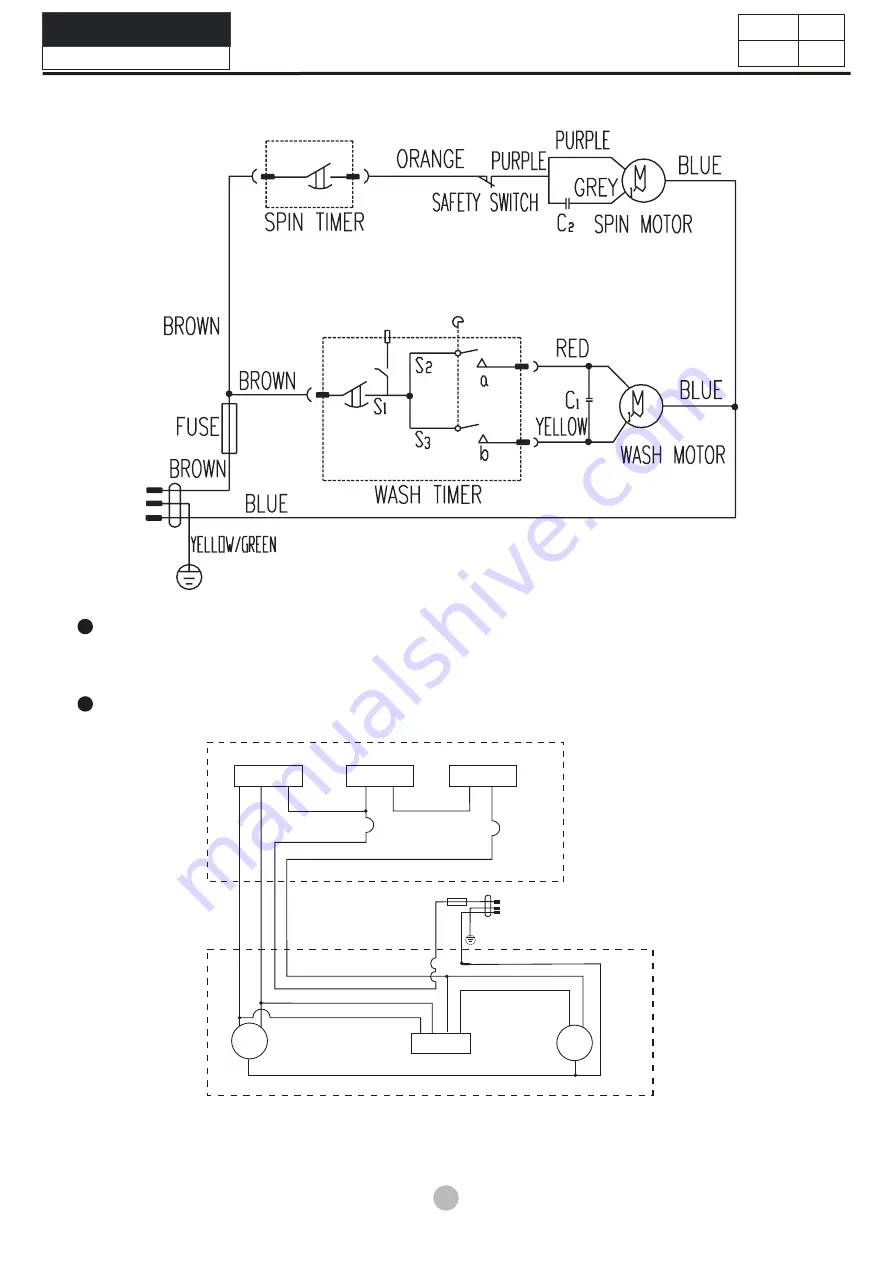

Actual Circuit Diagram

There is overload protector installed in the motor. In case that the motor is overload or meets

breakdown in working, the protector will act and stop the motor. When the breakdown is

removed, the motor will resume normal working.

Figure12

Chapter 10: WIRING DIAGRAM

18

Service Manual

Issue

Rev.

Model NO:LMD6124PBBB0

spin timer

microswitch

wash timer

wash

motor

capacitor

fuse

red

red

red

yellow

yellow

Grey

Grey

Grey

brown

brown brown

blue

Yellow/green

orange orange

purple

purple

purple

yellow

blue

Cabinet

Control

Panel

spin

motor