The factory charge is sufficient for 25 feet of standard liquid line. For longer or shorter liquid line

lengths, adjust the charge as follows:

1/4" Line +/- 0.3 oz. Per foot

5/16" Line

+/- 0.4 oz. Per foot

3/8" Line

+/- 0.6 oz. Per foot

1/2" Line

+/- 1.2 oz. Per foot

Vertical Separation between Indoor and Outdoor Units

Maximum allowable vertical separations between indoor and outdoor units are illustrated in

Figure

3-A and Figure 3-B

. It's 70' when the indoor unit is below the outdoor unit (Figure 3-A), and 50' when

the indoor unit is above the outdoor unit (Figure 3-B).

To ensure good oil return to the compressor when the indoor unit is below the outdoor unit, suction

line oil trap should be used as illustrated in Figure 3-A.

Tubing Connections

! CAUTION

- Use extreme caution in removing the caps from the suction and liquid line fittings, as

there is pressure present. A fitting is on the liquid line to remove pressure.

! CAUTION

- Condensing units are charged with refrigerant. Condensing unit liquid and suction

valves are closed to contain the charge within the unit. Do not force the valve stem against the retaining

ring. If the valve stem is backed out past the retaining ring, system pressure could force the valve stem

out of the valve body and possibly cause personal injury.

! CAUTION

- The piston is in the accessory bag. Don't forget to take it out and put into the indoor

liquid pipe orifice.

Instructions on the field tubing connections and valve opening procedure are as follow:

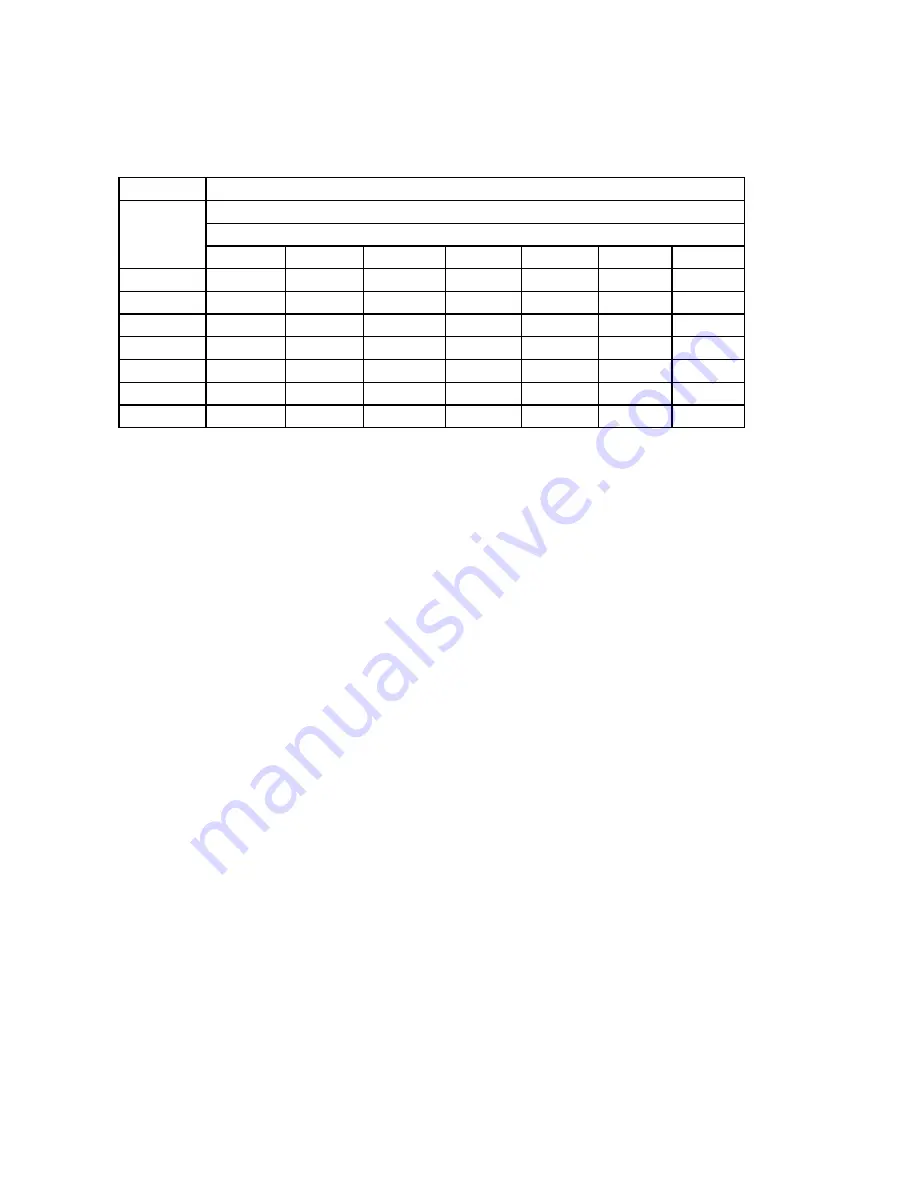

Refrigerant Line Sizing

Check the following table (

Table 2

) for correct suction and liquid line sizes for any combination of

the unit size and the maximum refrigerant line length.

Table 2:Refrigerant Line Sizing

Unit Size

(Ton)

Suction

Liquid

Suction

Liquid

Suction

Liquid

Seer

1.5

5/8

3/8

3/4

3/8

3/4

3/8

9

/10

2.0

5/8

3/8

3/4

3/8

3/4

3/8

9

/10

2.5

3/4

3/8

3/4

3/8

7/8

1

/

2

9

/10

3.0

3/4

3/8

3/4

3/8

7/8

1/2

9

/10

3.5

3/4

3/8

7/8

3/8

1 1/8

1/2

9

/10

4.0

3/4

3/8

1 1/8

3/8

1 1/8

1/2

9

/10

5.0

7/8

3/8

1 1/8

3/8

1 1/8

1/2

9

/10

50-74

Refrigerant Line Length(Ft)

Line Outside Diameter(In)

0-24

25-49

6

Summary of Contents for V1124C2H

Page 17: ...Made in P R C...