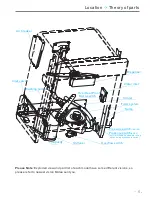

Inlet Valve

Theory of parts

-

>

Check machine part

1. If the electric part is OK, we need to check the machine part.

2. Remove the baseboard, left baseboard, top panel, left side panel and middle

rear

crosspiece.

3. Check the valve filter. if the valve filter is blocked, we need clear the residues.

4. If the valve filter is clear and the valve can’t inlet water, check whether valve can act or

not. If it isn’t , we need replace the valve.

5. If the water is continue entering, we need replace the valve.

-

10 -

Summary of Contents for WQP12-B9227E

Page 34: ...Troubleshooting 34 ...

Page 35: ...Troubleshooting 35 ...

Page 36: ...Troubleshooting 36 ...

Page 37: ...Troubleshooting 37 ...

Page 38: ...Troubleshooting 38 ...