17

en

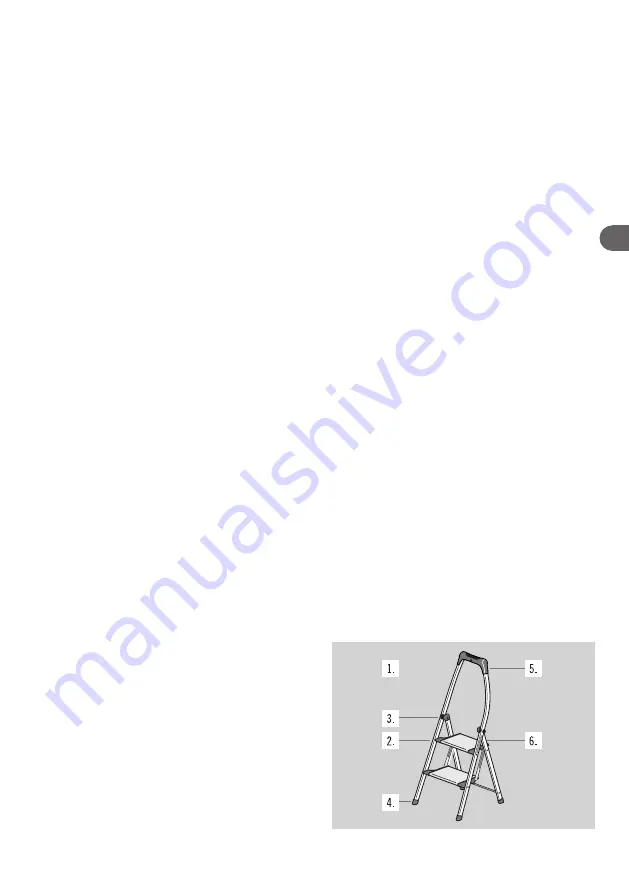

1. General inspection points

Are there any contaminants (e.g., dirt, mud,

paint, oil or grease) on the step stool?

All fastenings (rivets, screws, bolts, etc.) must

be completely present. Are any fastenings pos-

sibly loose or corroded?

2. Aluminium side rails, steps

Are step stool sides and reinforcement strips

possibly bent, curved, twisted, dented, torn,

corroded or rotten? The step stool sides must

be in a good state at the fixing points for other

parts. All steps must be completely present.

Are steps possibly worn out, loose, corroded or

damaged?

3. Joints, hinges

Check the function, strength and complete-

ness as well as for damage and corrosion.

Are hinges, joints possibly damaged, loose or

corroded?

4. Step stool feet

Inspect feet for tightness as well as damage

and corrosion. All feet must be present. Are any

feet loose, worn out or corroded?

5. Safety rail with tray

Inspect technical condition of the safety rail.

Are damage or cracks present?

6. Step stool markings

Are all labels present and perfectly legible?

• Regular inspection by a qualified person is required

for commercial use.

• The contractor has to ensure that step stools are

inspected recurrently for proper condition (visual

and functional inspection).

For this purpose, the type, scope and time periods

of the required inspections must be determined.

• The time intervals for the inspection will conform

to the operating conditions, in particular the fre-

quency of use and demands during use as well as

the frequency and severity of established defects

during the preceding inspections.

• The contractor also has to ensure that defective

step stools are removed from use and stored in

such a way that further use is not possible until

proper maintenance or disposal takes place.

• There exists the risk of a fall due to damaged,

defective or non- functional step stool units;

there is also a risk of tipping over when using the

step stool.

• Users of the step stool can sustain serious inju-

ries during a fall.

• Objects can likewise be damaged if the step stool

tips over.

During the regular inspection of the step stool,

inspection points 1-6 should be taken into account.

If any of the tested points cannot be fully satisfied,

you should NOT use the step stool.

11. Inspection plan

Summary of Contents for K100 TopLine

Page 74: ...74 1 2 3 4 5 6 7 8 9 10 11 e 74 75 76 77 77 79 80 80 80 80 81 76 1 4303 xxx 3 4302 xxx 2...

Page 75: ...75 ru A B A B C e A B C EN 14183 150 2...

Page 77: ...77 ru 1 1 5 4...

Page 78: ...78 5...

Page 79: ...79 ru 6 10...

Page 81: ...81 1 2 3 4 5 6 1 6 11 ru...

Page 82: ...82 84 4 5 1 1 2 3 4 5 6 7 8 9 10 11 82 83 84 85 85 87 88 88 88 88 89 4303 xxx 3 4302 xxx 2...

Page 83: ...83 ja A B A B C A B C EN 14183 150 kg 2...

Page 85: ...85 ja 5 4 1 x 1 x...

Page 86: ...86 5...

Page 87: ...87 10kg ja 6...

Page 89: ...89 ja 1 2 3 4 5 6 1 6 11...

Page 90: ...90...

Page 91: ...91...