-9-

7. OPERATIONAL INSTRUCTIONS

【

1

】

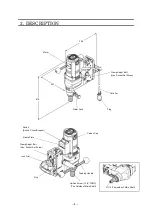

Anchoring Core Drill

◎

Core drill can be anchored by means of Anchor Bolt, Vacuum Pad or Support Jack.

Follow the below procedures for bolt anchor method.

【

2

】

Anchoring Core Drill by Anchor Bolt

1. Installation of anchor bolt

1) Drill anchor bolt hole, using a hammer drill.

2) Set anchor bolt (W1/2) into the hole.

2. Installation of core drill

1) Screw bolt (W1/2) into Anchor Bolt.

2) Insert bolt (W1/2) into the slot of Pole Base and fasten square washer and hex. nut (W1/2)

3) Install Drill Head onto pole.

4) Adjust the position of Pole Base so as to align main shaft with the hole to be drilled.

5) Adjust leveling with leveling bolts so as to eliminate rattling of pole base. After completion of

adjustment, secure leveling bolt with wing nut.

6) Tighten hex. nut (W1/2) to secure Pole Base.

7) Set desired rotating speed with speed change knob.

3

.

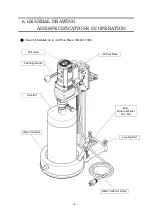

Installation of core bit

◎

Thread core bit onto main shaft.

4

.

Installation of Water Collector

◎

Secure Water Collector with Water Collector Fitting.

5

.

Arrangement for water disposal

◎

Receive water into a bucket by connecting a hose with drain port of water collector or suck

water through drain port using a vacuum cleaner.

6. Arrangement for water supply

◎

Connect a hose between a water source and water cock using Hose Adapter.

WARNING

Be sure to use Water Collector to prevent spattered water from getting into

motor

during operation.

WARNING

Do not stop water supply during operation.