-11-

6

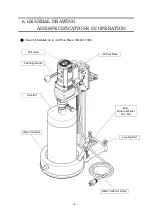

8. MAINTENANCE AND SERVICING

【

1

】

Maintenance

1) Clean the surface of the machine after using.

Regarding the outer frame of the Drill Head, the part of the gear case is made of aluminum,

and the part of the motor is made of the sturdy synthetic resin.

If gasoline, thinner, petroleum or kerosene are adhered to the outer frame of the Drill Head,

the surface of the Drill Head will be damaged.

When you clean the out frame of the Drill Head, use the dried cloth or the cloth which is

soaked with the soapy water.

2) Maintenance for motor.

After entire operation is over, secure Drill Head onto Pole Base, run motor with no-load and

remove dirt and dust from motor interior.

【

2

】

Regular Servicing

1. Checking of Carbon Brush

1) How to check

Remove Carbon Brush Cap using the flathead screw

driver etc., and take Carbon Brush out. After

inspecting, tighten the carbon cap.

2) Item to be checked

○ If the wearing of the Carbon Brush increases, it will

be caused motor failure. Check it regularly, and if

the length of carbon brush is worn up to the wear

limit line (6mm), replace with new ones.

○ Keep the Carbon Brush clean for free sliding in brush holder.

CAUTION

Use HAKKEN genuine Carbon Brushes for replacement.

Carbon Brush