28 / 48

Hakki Pilke 55 Pro

Translation

Version 3-2022

4.6.

After use

1.

After you have finished making firewood, stop the out-feed conveyor, shut down the machine and

remove the firewood from the splitting groove and conveyor.

2.

Ensure that the machine has not been damaged.

3.

Ensure that the machine can be moved safely off the processed firewood.

4.

Clean the machine.

If you will not be using the firewood processor for a while, do the following:

5.

Store the machine according to the instructions in Section 10.

5.

Machine maintenance

The machine must be disconnected from its power source before any maintenance, adjustment,

replacement or cleaning measures. Only use spare parts that are supplied by the manufacturer or your

retailer. If the guards of the machine have to be removed for maintenance, they must always be reattached

before the machine is activated. After maintenance and adjustment measures, the machine must be test

run according to the instructions in Section 4.1.

5.1.

Cutting blade and drive end

If the cutting blade of the machine does not penetrate the wood properly or the cut is skewed, the cutting

chain is most likely blunt or the saw bar is bent.

The most common cause for problems with cutting logs is

an unevenly dulled saw chain which veers 5

–

10 cm to either side and causes the saw bar to stop.

It is a

good idea to keep a replacement chain on hand, so that you do not need to interrupt your work to sharpen

the chain.

5.1.1.

Replacing and tensioning the saw chain

The Hakki Pilke 55 Pro firewood processor comes standard with a patented AC10

™

automatic and

hydraulically powered saw chain tensioner. When the machine is running, the hydraulic cylinder pushes the

saw motor backwards with a constant force, keeping the saw chain’s tension optimal. The o

perator does

not need to worry about the saw chain’s tension.

Replace the saw chain, as follows:

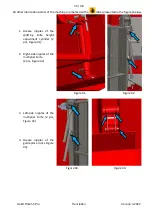

1. Turn off the machine, disconnect it from its power source and open the left and right guard.

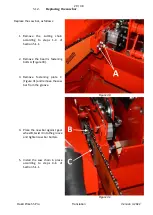

2. Turn lever B (Figure 9) to the OFF position to release the pressure in the automatic cutting chain

tensioner.

3. Pull the cutting chain downwards at the middle of the beam. This will loosen the chain and allow you to

remove it.

Note! Always wear cut protection gloves when handling the saw chain.

4. Install the new saw chain and ensure that the cutting teeth come first in relation to the rotating direction.

5. Turn lever B in Figure 9 to the ON position.

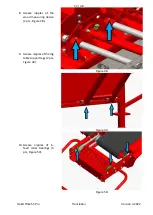

6. Close the machine guards and turn on the machine. This will automatically tension the cutting chain to

the right tension and raise the saw bar.

To check the tension of the cutting chain, wear protective gloves and pull the lower edge of the chain at

the middle of the beam. The tension is correct when you cannot pull a drive tooth to a fully visible position

with moderate force, but the chain moves on the bar when pulled with a tool.