HAKKI PILKE RAVEN

TRANSLATION

VERSION 1-2015

6.

Use a winch to lift the conveyor to the

desired angle (max 40°) and lock the

upper section of the output conveyor to

the operating position using lock D (Fig-

ure 8).

Figure 8.

Place the output conveyor in the transport position as follows:

1.

Turn off the machine.

2.

Release lock D (Figure 7) and lower the conveyor to the lowest possible position with the winch.

3.

Turn support bar C (Figure 7) to a position over the belt, and turn the upper section of the con-

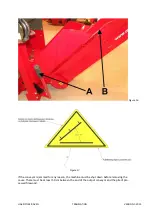

veyor onto the lower section using handle B (Figure 5).

4.

Turn the conveyor to the middle position (only in machines with a pivoting conveyor). See Sec-

tion 3.6.

5.

Lift the conveyor with the winch until it locks into the raised position. Ensure that lock A (Figure

5) settles properly into place.

Note! Do not stand on the output conveyor! Do not use the winch if the belt is worn!