31 / 35

Hakki Pilke XL - Conveyor

Translated

version 4-2021

2.10.

Machine maintenance

The machine must be disconnected from its power source before any maintenance, adjustment,

replacement or cleaning measures. Only use spare parts that are supplied by the manufacturer or your

retailer. If the guards of the machine have to be removed for maintenance, they must always be reattached

before the machine is activated. After maintenance and adjustment measures, the machine must be test

run according to the instructions in Section 4.1.

2.11.

Lubrication

All other lubrication points of the machine are marked with a

label presented in the figures below.

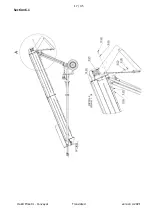

1.

Bottom

roller

nipples

(2 pcs, Figure 9).

2.

Turning

device

nipple

(1

pc,

Figure 10).

Figure 9.

Summary of Contents for XL Conveyor 1

Page 9: ...9 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 1...

Page 10: ...10 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 2 1...

Page 11: ...11 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 2 2...

Page 12: ...12 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 2 3...

Page 13: ...13 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 3...

Page 14: ...14 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 4...

Page 15: ...15 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 5 1...

Page 16: ...16 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 5 2...

Page 17: ...17 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 6 1...

Page 18: ...18 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 6 2...

Page 19: ...19 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 6 3...

Page 20: ...20 35 Hakki Pilke XL Conveyor Translated version 4 2021 Section 7...