Comparison with new parts using

photo image

Case 5:

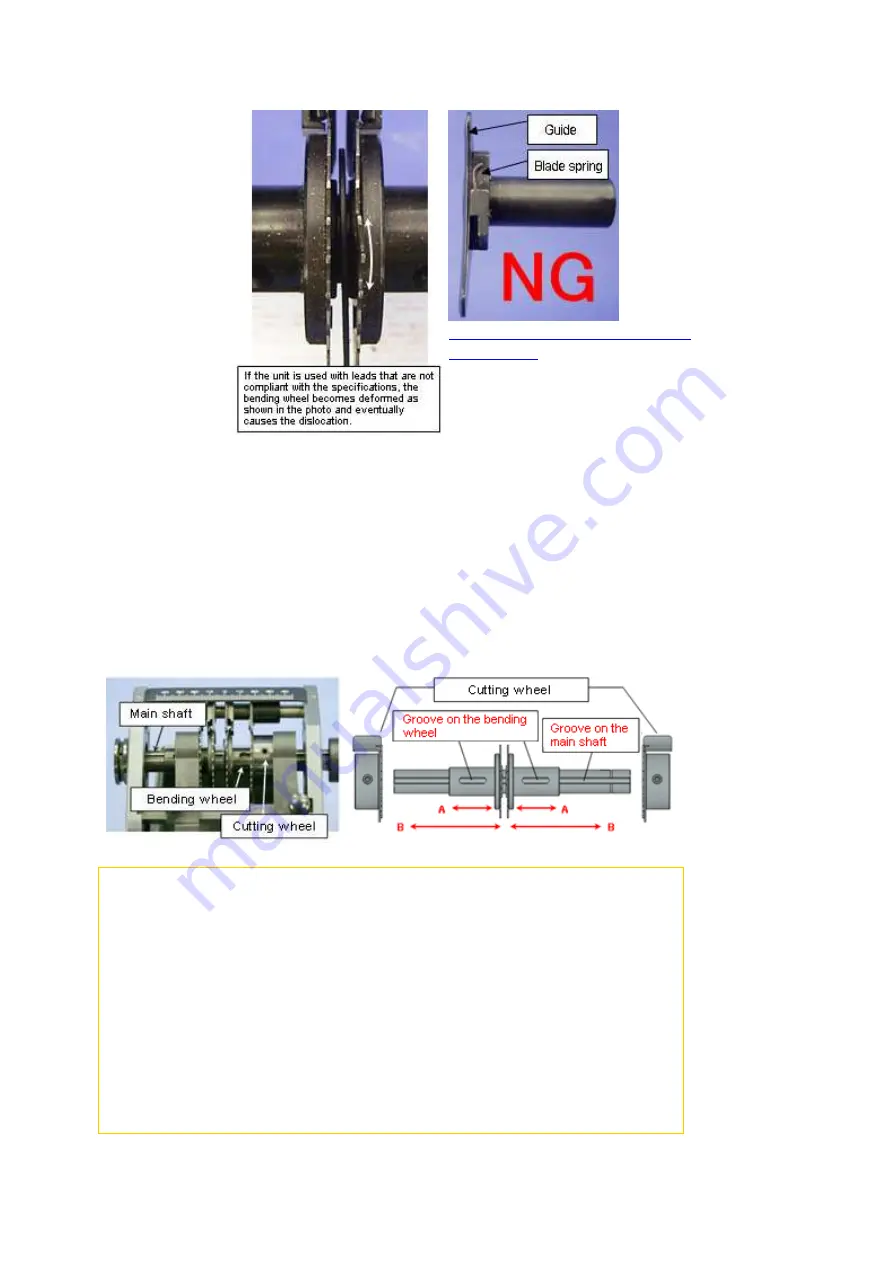

Adjustment of parts such as bending wheels and cutting

wheels is becoming increasingly more difficult. Why?

The probable cause is the deterioration of shaft and bending wheel.

If the unit must be adjusted often due to the frequent changes of pitches to form (e.g. after

each set of work), the grooves on the main shaft and bending wheel (where the screws touch)

are scratched, and the unit will not operate smoothly.

1. When the cutting wheel does not operate smoothly

Burrs are formed on the part of the bending wheel where the cutting wheels

can traverse (A).

Polish the part around the groove on the bending wheel with a file.

*To file the groove on the bending wheel, first remove it from the main shaft.

2. When the bending wheel does not move smoothly

Burrs are formed on the part of main shaft where the bending wheels can

traverse (B). Polish the part around the groove on the main shaft with a file. If

the movement does not improve, the shaft may be bent.

Replace it with a new one.

* To file the main shaft, first remove it from the Lead Former.