First Edition: March 31, 2007

2-4 Voltage Application Check (FX-951/FH-200)

(5) Check the offset value.

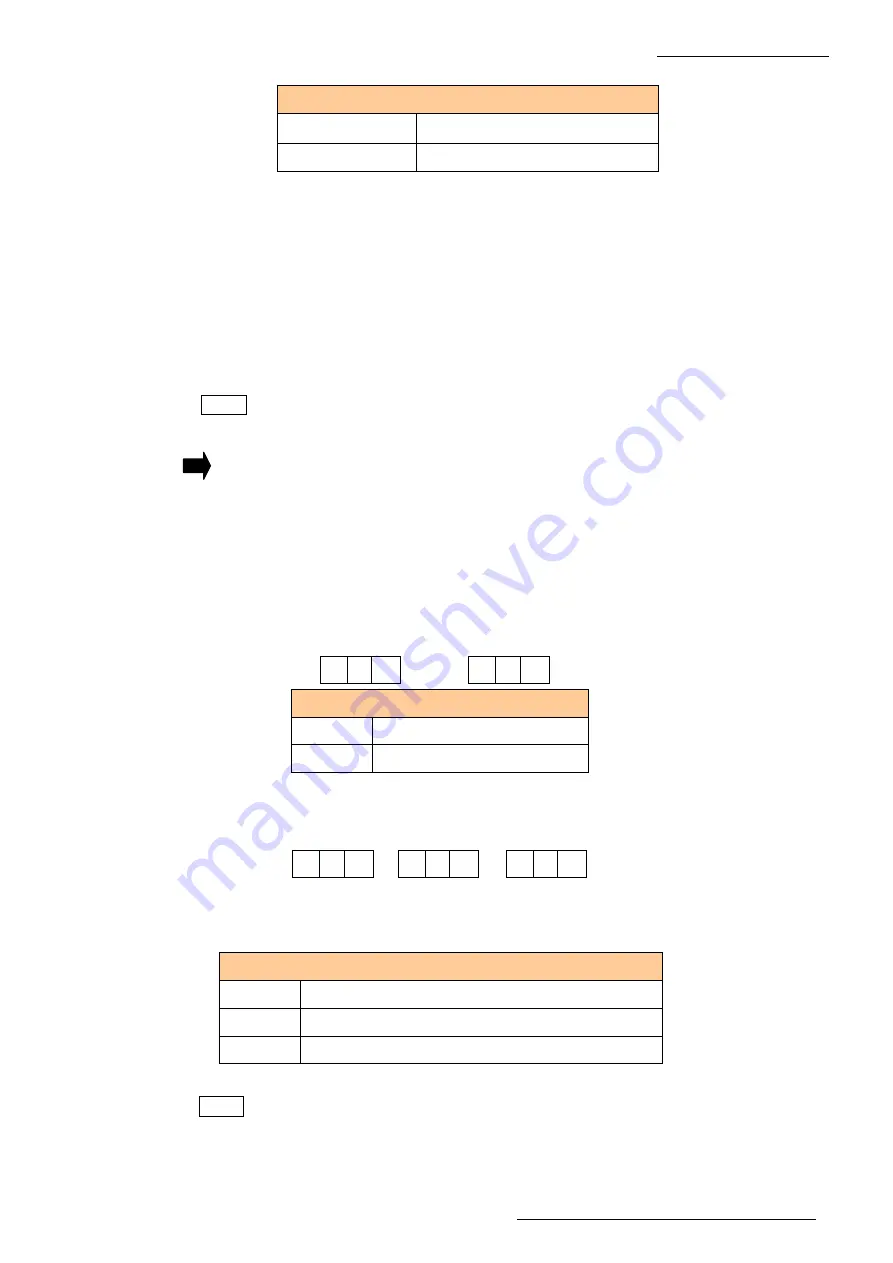

Input range for the offset value

In Centigrade

-50°C to + 50°C

In Fahrenheit

-90°F to + 90°F

1. Hold down [#] for one second or longer to make the indicator [Left] flash, indicating

“0” or “-”.

2. Press [UP] and [DOWN] to check that the indication changes alternately between [0]

and [-].

3. Indicator [Center] flashes by pressing [*]. Press [UP] and [DOWN] to check that the

indication changes within the input range.

4. Indicator [Right] flashes by pressing [*]. Press [UP] and [DOWN] to check that the

indication changes within the input range.

5. Press [*] to return to usual operations.

NOTE

If an input range of offset values is exceeded, the operation returns to the

beginning.

If the unit does not operate correctly:

The P.W.B. is faulty. Check the P.W.B. using the procedure in step (7).

(6) Check the parameters.

1. Turn off the power switch before inserting the card.

2. If turning on the power switch while pressing the [UP] and [DOWN] at the same time,

the mode will change to the temperature scale setting.

•

Check that pressing the [UP] and [DOWN] changes the indication alternately as

follows:

3. Pressing [*] accepts the indicated setting and proceeds to the “

Power save

setting

”.

•

Check that pressing [UP] and [DOWN] changes the indication within the input range.

NOTE

Check the power-save operation according to the procedure in Section 2-5: "Iron

Holder Check “

1

C

1

F

Temperature scale setting

C

Centigrade (°C)

F

Fahrenheit (°F)

Power save setting

0

OFF

1 to 29

Indicates “SLP” after the set time has elapsed.

30

Indicates “---” after 30 minutes.

2

0

2

1

2 3 0

* The above example

shows the case when it

is set to 1 min.