10

To change the offset value with the

control card in the station:

●

Removing solder

Clean the nozzle tip.

Be sure the nozzle tip is tinned with clean,

fresh solder.

If the nozzle tip is coated with oxidation

or contamination, its thermal conductivity

deteriorates. In contrast, if the nozzle end is

wetted with a small amount of clean solder,

its thermal conductivity increases.

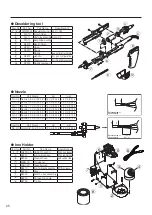

1. Melt the solder.

Position the nozzle above the lead to be

desoldered as shown in the illustration and

melt the solder.

CAUTION

Never allow the nozzle to touch the board itself.

Confirm that the solder is melted.

CAUTION

To confirm that all solder is melted, observe the inside of

the hole and the backside of the P.W.B. If this is difficult to

do, try slowly moving the lead with the nozzle. If the lead

moves, the solder is melted. Never move the lead by force.

If it doesn’t move easily, the solder isn’t yet fully melted.

2. Extract the solder.

After confirming that the solder is completely

melted, extract the solder by pressing the

button (or squeezing the trigger).

CAUTION

Never leave any solder remaining inside the hole in the

P.W.B.

3. Problems during desoldering.

If solder remains, resolder the component and

repeat the desoldering process.

1. Press and hold the button for at least

one second.

The current offset value is displayed, and then

the hundreds digit begins to flash one second

later. This indicates that the station has

entered the offset entry mode. Follow steps

3 and 4 for setting the offset value of the tip

temperature.

2. If the button is not pressed and held

for at least one second, the current

OFF set value is displayed, and then the

temperature setting is displayed.

Nozzle

P.W.B.

Solder

Lead

Slowly move

the lead with

the nozzle.

Extract the solder by slowly

moving the lead back and forth

with the tip of the nozzle.