10

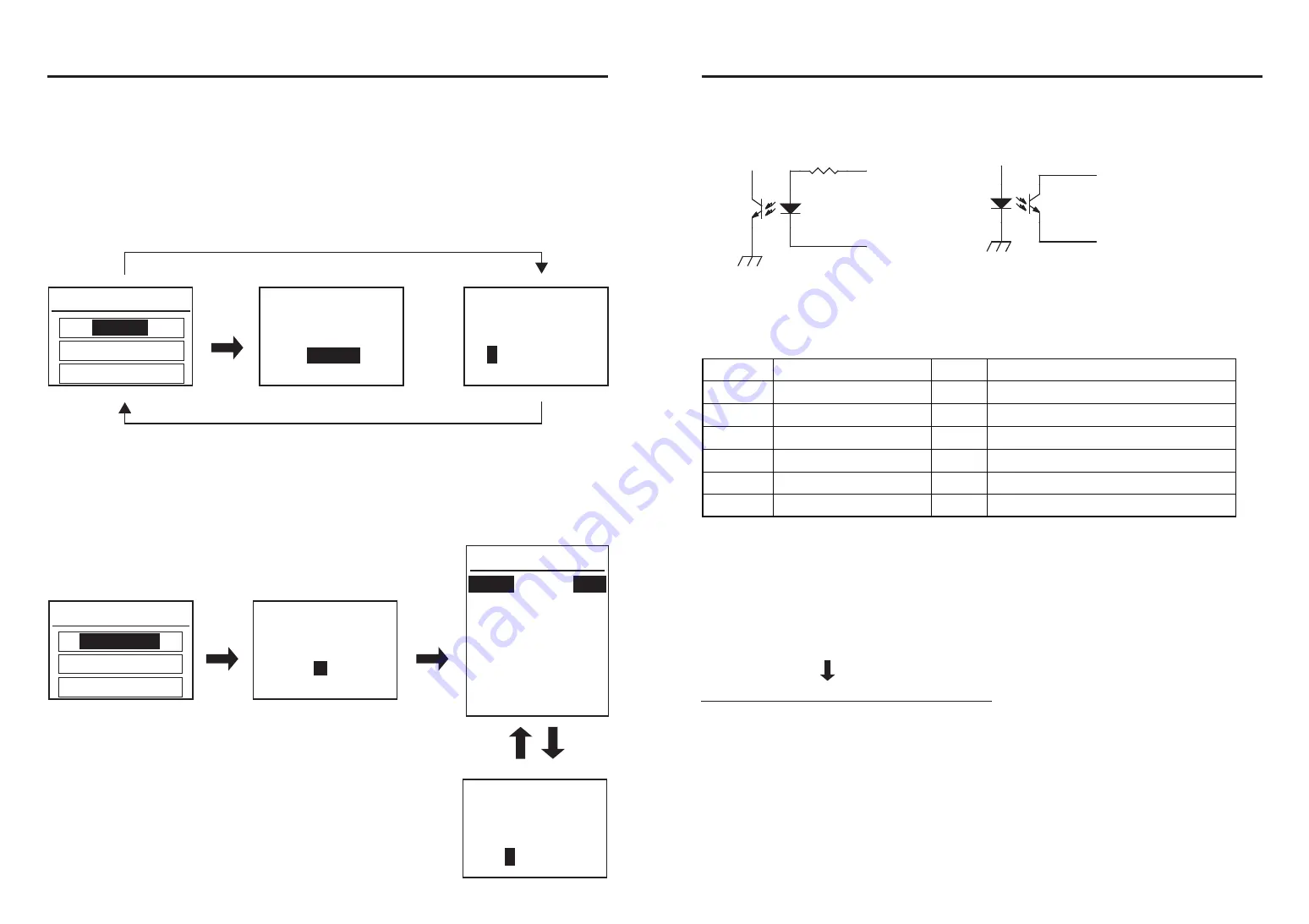

Input circuit

2

〜

10mA

(24V recommended)

1

2

4

3

In

IO_Vsup

Output circuit

1

2

4

3

Out

IO_GND

DCV48 or less, 50 mA or less

5.6K

Robot I/F input and output circuits

Pin No.

1

2

3

4

5

6

Signal name

RxD

TxD

Iron_Ready

Iron_GND

Iron_GND

Iron_Vcc

I/O

In

Out

In

In

Function

Incoming data

Outgoing data

HAKKO FU-601 Ready signal

HAKKO FU-601 GND

HAKKO FU-601 Vcc (5V)

HAKKO FU-601 I/F

Connecting cable (6-pole 6-core modular cable)

It transfers status and data to and from the HAKKO FU-601.

13

●

Selecting Solder Feed

When you select Solder Feed, you will enter Solder Feed Mode.

In this mode, you will specify the solder feed speed for continuous feed of solder.

No signal will be output to the robot. All input signals from the robot will be ignored and

no solder feed error will be detected.

Setting completed

Select SET FEED SPEED

START

●

Selecting Program Set

When you select Program Set, you will enter Program Setting Mode.

Up to 100 programs (0 to 99) can be programmed in either

PS (point soldering) or DS (drag soldering) mode.

Any other

than Exit

※Tens place -> Units place -> Confirm

※Tens place -> Units place ->

One decimal place -> Confirm

※For feed amount or feed speed, tens place -> units place -> one decimal place.

For heating time, units place -> one decimal place.

Select

program No.

Solder Feed

Select Feed Mode

START

SET FEED SPEED

Exit

Solder Feed

STOP

Feed Speed

1

0.0mm / sec

PS Mode

DS Mode

Exit

Select

Program Number

0

0

Primary

Feed Length

1

0.0mm

PC I/F : USB Mini-B

The PC I/F establishes communications with PC to send and receive various information.

It is operated on a virtual COM port.

Please install the driver (freeware) to your PC from the following URL:

http://www.cypress.com/?rID=63794

From the top page, proceed as follows:

(Support > Software Tools > Software and Drivers > Microsoft Certified USB UART Driver)

1) Uploading/downloading programs

The PC I/F writes (downloads) programs created in the PC to the controller or reads in and

uploads programs to the PC.

2) Uploading/downloading the HAKKO FU-601 setting information

The PC I/F uploads or downloads the set temperature, the offset temperature and the preset

temperature of the HAKKO FU-601.

Select Parameter

Feed1

Feed Speed1

Back Feed1

Back Speed1

Heat Time1

Feed2

10.0

10.0

01.0

02.0

2.0

10.0

...

Exit

DC24V OUT 500mA Max