7

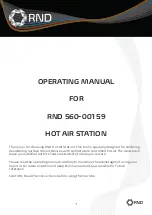

6. OPERATION

Auto mode

In auto mode, the unit operates according to commands from the robot.

There are two types of auto mode: PS and DS.

For more information, see the timing chart below:

・

PS (Point soldering) mode

Point soldering process

*

When selecting a program number, set the signal P7 (MSB) to 0 (zero).

*

The controller outputs either the status signal Form1 or Form2

(according to the setting made during program setting).

Program selection setup time : t

ps

>

5msec

Program selection hold time : t

ph

>

25msec

Start signal pulse width : t

sw

>

25msec

Program No. (In)

Start solder feed (In)

Controller ready (Out)

Primary feed (Internal)

Primary back feed (Internal)

Unit down command (Out)

Upper limit detection (In)

Lower limit detection (In)

Primary heating (Internal)

Secondary feed (Internal)

Secondary back feed (Internal)

Secondary heating (Internal)

Tertiary feed (Internal)

Tertiary back feed (Internal)

Tertiary

heating (Internal)

Status signal: Form1 (Out)

Status signal: Form2 (Out)

Run

16

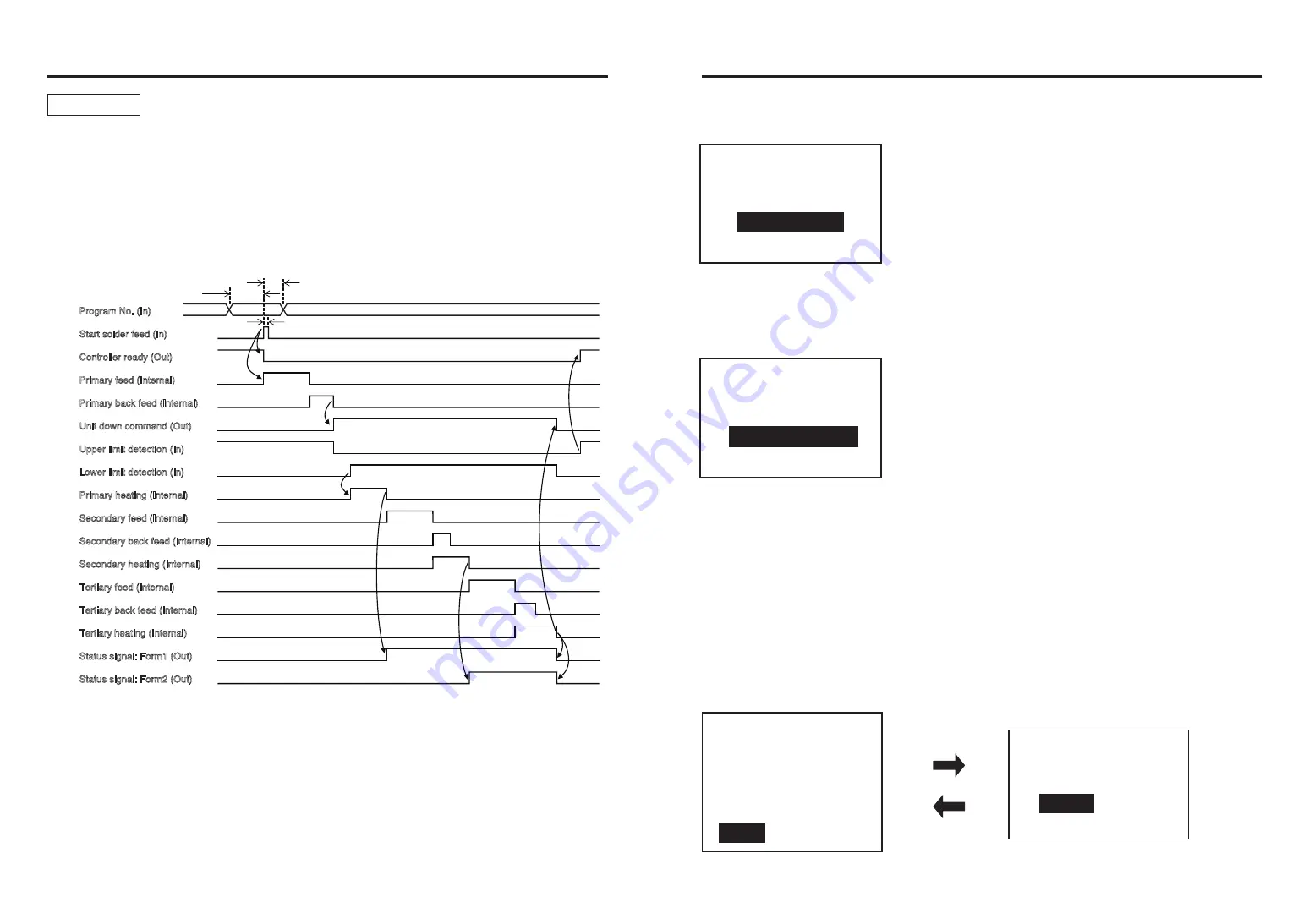

4. Iron Connect (Connection status to the HAKKO FU-601)

Connection or Disconnection

When Not Connect is selected, preset settings can only

be made in the HAKKO FU-601 and no iron controller

error is detected.

5. Iron Status (Selecting the HAKKO FU-601 Ready or Error signal)

You can select which signal HAKKO FU-601 will output

to the robot, Ready or Error.

Iron Control

Connect

Connection

Disconnection

Iron Control

Status

Iron Ctrl Ready

Iron Ctrl Error

●

Selecting Log View

When you select Log View, you can view the number of soldering points that have been made

and the total amount of solder that has been fed.

If you select Log Clear, you will enter the Log Clear screen. Selecting OK in this screen will

reset the count and you will enter the Mode Select screen.

If you select Cancel, you will return to the previous screen.

Log Clear

Operation Log

Total Point

xxxxxx p

Total Feed

xxxxxx mm

EXIT

Log Clear

Log Clear ?

Cancel

OK

Cancel

On

Off

On

Off

On

On

On

On

Off

Off

Off

Off

t

ps

t

ph

t

sw