7.

CHECK PROCEDURE

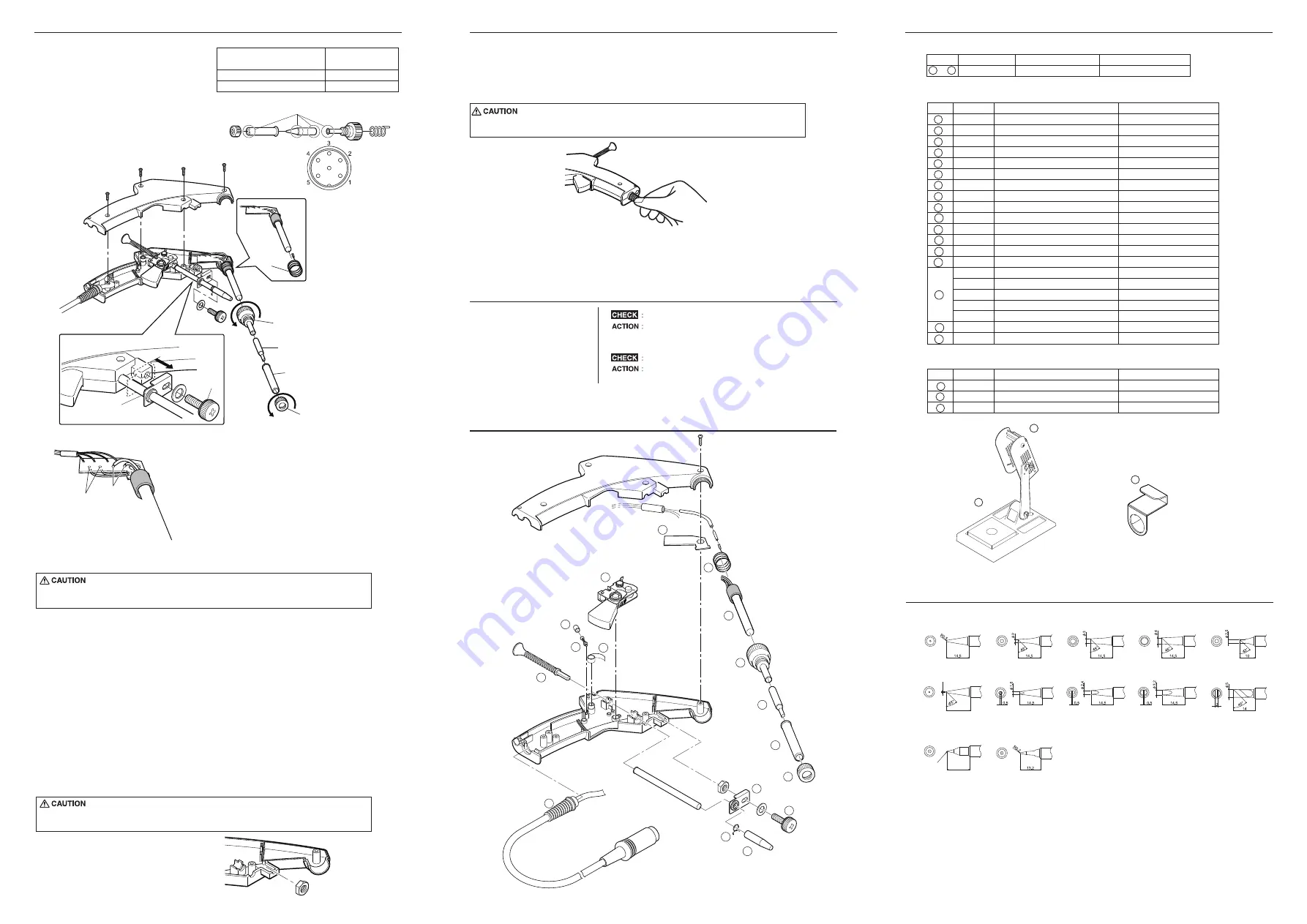

2. Broken cord assembly

7. CHECK PROCEDURE

Resistance value

of heating element

Resistance value

of sensor

●

Soldering gun parts

●

HAKKO FX-8803

10. TIP STYLES

9. PARTS LIST

9. PARTS LIST

6

7

8

1

2

3

4

5

9

10

11

14

16

17

12

Hexagon nut M4

15

●

Option

1

2

3

13

●

●

There are two methods of testing the cord assembly as below.

1. Turn the power on and set the temperature control knob to 480℃. Then, bend the iron cord at

various locations along its length, including in the strain relief area.

If the LED heater lamp flashes, then the cord needs to be replaced.

2. Check the resistance between the plug pin and the terminal lead.

Pin 1: Red Pin 2: Blue Pin 3 : Green

Pin 4 : White Pin 5 : Black

If it is higher than 0 Ω or ∞, the cord should be replaced.

B2643

B2032

A1560

B2022

B3469

B1785

B2648

B2646

B2645

B2658

B2657

B3467

B1710

B2652

B2653

B2654

B2655

B2656

B2649

B2650

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

26V-65W

See “10.TIP STYLES”

With nut

0.6mm ESD

0.8mm ESD

1.0mm ESD

1.2mm ESD

1.6mm ESD

With grommet

For guide pipe

Terminal board

Grounding spring

Heating element

Nipple

Tip

Tip enclosure

Nut

Trigger set

Solder feed adjusting screw guide

Solder feed adjusting screw

Spring for trigger assembly

Solder inlet

Cord bushing

Nozzle securing ring

Guide nozzle

Guide nozzle

Guide nozzle

Guide nozzle

Guide nozzle

Support fitting

Adjudting screw

Item No. Part No.

Part Name

Specifications

FX8803-02

HAKKO FX-8803

1

〜

17

26V-65W

Part No.

Item No.

Part Name

Specifications

C1437

A1042

B2723

1

2

3

With cleaning sponge

With screw

Iron holder

Cleaning sponge

Hook

Part No.

Item No.

Part Name

Specifications

T18-B

T18-C2

T18-CF2 *

T18-C3

T18-CF3*

T18-C4

T18-CF4*

T18-CSF25*

T18-K

T18-D16

T18-D24

T18-D32

T18-S4

R0.125

14.5

T18-C08

15.5

φ0.8

T18-SB

* Tinned on the soldering surface only.

The power lamp starts to flash when the temperature reaches 480℃ regardless of the

condition of the cord.

8. TROUBLE SHOOTING GUIDE

Do you pull solder from a reel when using the trigger?

Do not pull solder from a heavy reel with the trigger.

Keep the solder loose (without tension) on the solder

inlet side at all times while soldering.

Is the solder inserted properly?

Refer to “1.Inserting the solder” under “5.OPERATION”.

●

Solder gets stuck

1. Broken heating element / sensor

Disconnect the plug of the cord assembly

and measure the resistance value

between the pin of the connecting plug as follows.

If the values of “a” and ”b” are outside

the value in the table, replace the heating

element(sensor) and/or cord assembly.

If the value of “c” is over the value in the

table, remove the oxidization film by lightly

rubbing with sand-paper or steel wool

the points shown in the drawing on the right.

a. Between pins 4 & 5

(heating element)

b. Between pins 1 & 2 (Sensor)

c. Between pin 3 & tip

2.5 ~ 3.5 Ω

(at time of room temperature)

43 ~ 58 Ω

2 or less Ω

Rub lightly with sand-paper or

steel wool.

Grounding

spring

Nipple

Tip

Tip enclosure

Nut

Support fitting

Adjusting

screw

1. Remove the adjusting screw and keep the support fitting apart from the housing.

2. Turn the nut counterclockwise and remove the tip enclosure and tip.

Be sure to remove the nut before removing the nipple. Removing the nipple first

could cause the heater leads to twist and cause a short circuit.

3. Turn the nipple counterclockwise and remove it from the gun.

4. Remove the 4 screws and open the housing.

5. Pull the grounding spring out of the sleeve.

*Measure when the heating element is at room temperature.

1. Heating element resistance (red) 2.5-3.5

Ω

2. Sensor resistance (blue) 43-58

Ω

If the resistance value is not normal, replace the heating element.

(Refer to the instructions included with the replacement part.)

After replacement

1. Measure the resistance between pins 4 and 1, 4 and 2, 5 and 1, and 5 and 2.

If it is not ∞, the heating element and sensor are touching. This will damage the circuit board.

2. Measure the resistance “a”, “b”, and “c” to confirm that the leads are not twisted and

that the grounding spring is properly connected.

When reassembling, be sure to match the convex part of the hexagon nut to concave

part of the housing.

Hexagon nut M4