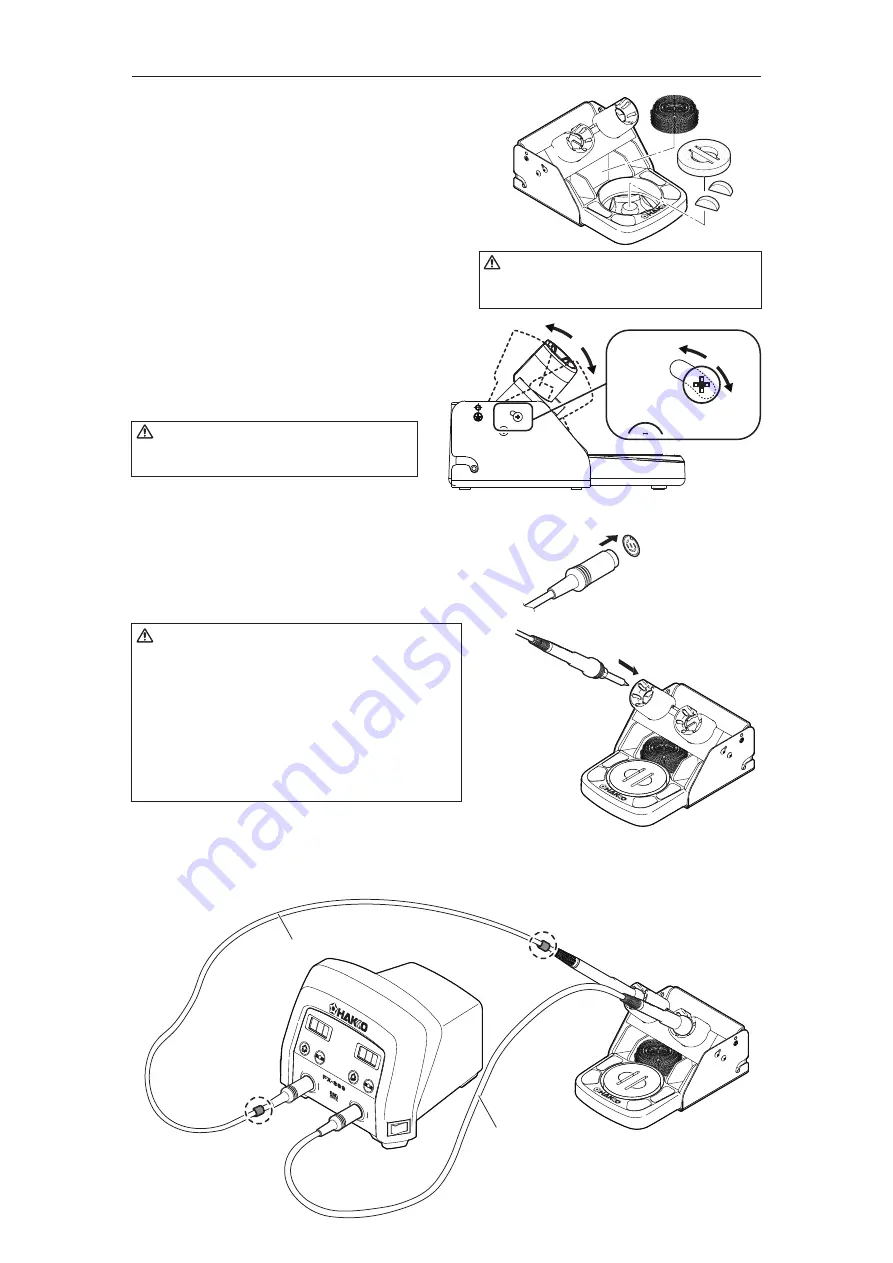

4. INITIAL SETUP

A. Setup the iron holder

(1) Cleaning Sponge

1. Fit the small sponge pieces into the hollows of the

iron holder base.

2. Add an appropriate amount of water into the iron

holder base. The small sponge will absorb water

and help keep the large sponge damp at all times.

3. Dampen the large sponge and place it on the iron

holder base.

(2) Cleaning Wire

Place it in the iron holder as shown on the right.

See “B. Using the cleaning wire” in section

“7. MAINTENANCE”.

The angle of the iron receptacles is adjustable by

changing the fastening position of the screws.

B. Connect the iron to the station

1. Connect the cord assembly to the receptacle.

2. Place the iron into the iron holder.

3. Plug the power cord into an appropriate power

supply.

※ When using two soldering irons simultaneously

Attachment of the color bands to one of the soldering irons will help identify which soldering

iron is connected to receptacle “A.IRON” and “B.IRON”.

(1)

(2)

CAUTION

Be sure the sponge is moistened with water

before use to avoid damaging the tip.

CAUTION

Increasing the angle of the iron receptacle will

cause an increase in the iron grip temperature.

CAUTION

• Be sure to turn off the power before connecting or

disconnecting the cord assembly for the iron to and

from the receptacle to avoid damaging the circuit

board.

• Do not use any iron other than those listed in Section

1 of this manual. Doing so may result in inadequate

performance and / or possible damage to the unit.

• The unit is protected against electrostatic discharge

and must be grounded for full efficiency.

Push on the plug until

it stops, making sure it is

securely connected.

Receptacle

To disconnect, hold the plug

and pull it out of the receptacle.

With color bands

Without color band