46

7. Operation (continued)

(10)

Move

Moves to the set Start Pos./OFFSET or end point coordinates. If the value is blank, no movement

will be performed.

If the end point is blank when the start point is an offset, no movement will be performed even if

[Move]

on the start point side is tapped because calculation cannot be performed.

(11)

Individual point settings

Sets the Lifting Pos., Moving Speed, Soldering Speed, and Lifting Speed for individual points.

If a value is blank, the values in the top screen will be applied. When numerical values are input

for the Lifting Pos., those values will be used even if Z axis absolute lift position is not checked in

the top screen.

(12) CLEANING settings

Select from the cleaning numbers

[1]

–

[5]

set in the Cleaning Settings Screen. The cleaning

timing can be set as before or after soldering of that point. For details on cleaning settings, refer

to “7-1-2 Cleaning Settings” (p. 47).

(13) Soldering

Select from PS (point soldering), DS (drag soldering), or None (movement only)

(14) Preset No.

Sets the soldering conditions number. Settable range: 1 – 250

(15) Return to

Sets the movement destination for after solder completion. For start point, movement will be to the

start point or offset destination; for Z lift position, movement will be vertically to the Z axis lift position.

(16)

Palletizing

When checked, palletizing settings can be performed. Palletizing is used when the settings

for a created point will be repeated multiple times.

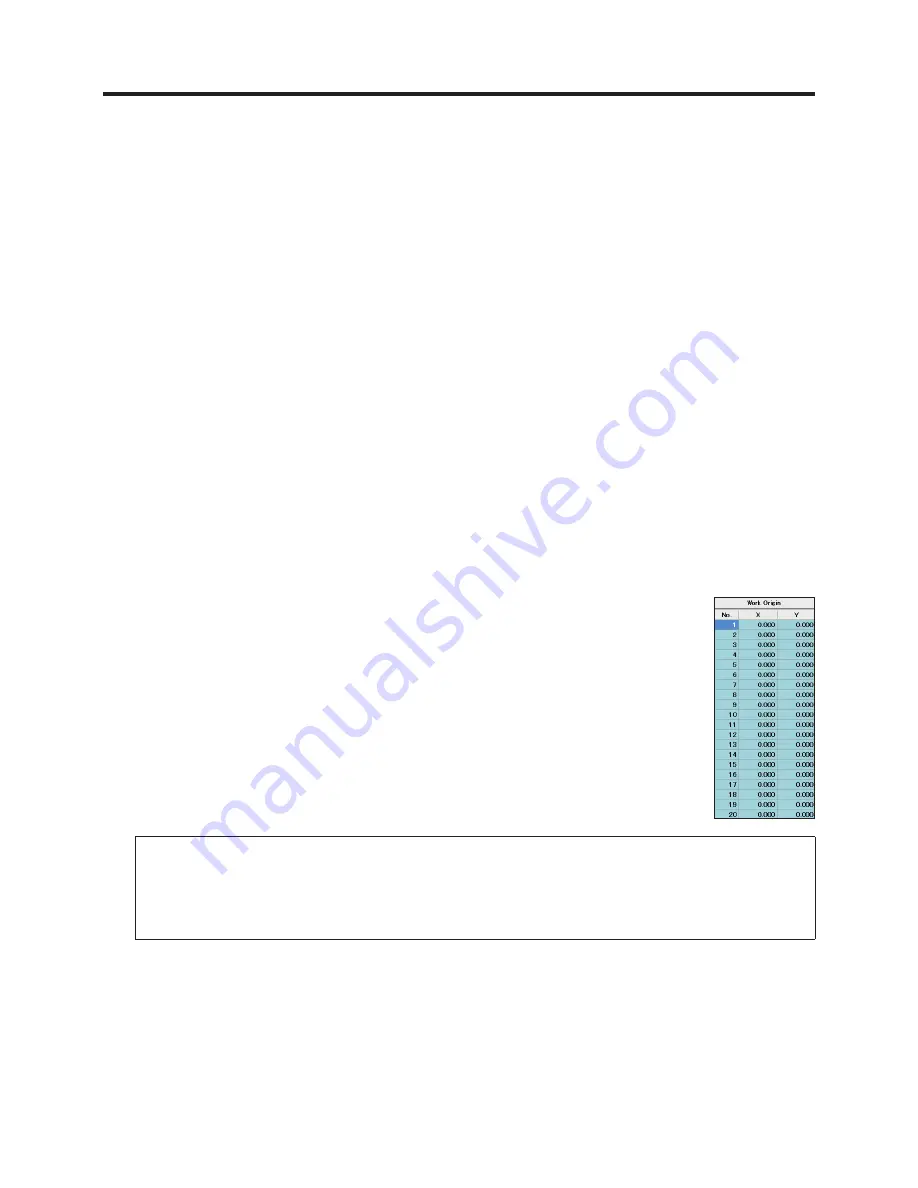

(17) WORK ORIGIN

Sets the WORK ORIGIN number in the

Work Origin

screen.

When blank, X=0.000, Y=0.000 will be used as the Work Origin.

(18) Cancel

Discards the points currently being edited and closes the screen.

(19)

Prev.

Moves to the previous point.

(20) Next

Moves to the next point.

— Note —

If the necessary settings for start point coordinates, end point coordinates, and soldering

conditions have not been set, a setting error will be shown and movement to the next Point Edit

Screen will not be performed. If the next point is a new point, it will inherit the start point/offset

display and soldering conditions.

(21) I/O Settings

Opens the point I/O Settings Screen. For details on the I/O Settings Screen, refer to “7-7-4 I/O

Settings” (p. 109).

(22) Exit

Finishes the settings and closes the current Point Edit Screen. If the necessary settings for start

point coordinates, end point coordinates, and soldering conditions have not been set, a setting

error will be shown and the screen cannot be closed. However, if movement to a new row has

been performed using

AUTO SET

or

[Next]

and all coordinate values are blank, the point

currently being edited will be discarded and the screen will close.