6

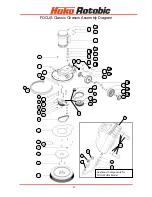

TRANSPORTATION

For transporting the machine on level surfaces

adjust the handle in an upright position, and

transport the machine on the back wheels refer to

Pic 21.

When transporting the machine and stairs are

encountered mechanical lifting aids should be

used. Do not transport the machine up stairs by

pulling on the handle, this practice increases

forces on the operator that can cause injury.

Where lifting of the machine is inevitable operators

should be trained in team lifting and manual

handling techniques.

PAD AND BRUSH MAINTENANCE

Replace brushes and pads that are excessively

worn, to reduce the risk of floor damage.

Wash pads on a regular basis and then store to

dry.

Excessive amounts of polish congealed on brush

bristles or embedded in the pad will cause

excessive drag, that can over load the machine.

For best results use clean or new brushes and

pads.

Abrasive materials embedded in pads can scratch

the floor surface. Ensure clean pads are used.

Remove brushes and pad holders from the

machine when stored. In storage the weight of the

machine can deform these parts causing the

machine to vibrate on the next use.

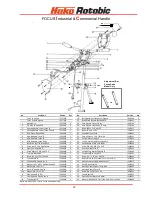

POWER CORD MAINTENANCE

Unplug the electrical cord from the power outlet

when the machine is not in use, or when cleaning

or maintaining the machine.

Wind the power cord between the handle and cord

storage arm from the machine end to reduce

knuckling, check for damage, and remove soilage

as shown in Pic 22.

Replace cords that are badly kinked, knuckled, cut

or damaged.

If the cord is damaged it must be replaced with the

original manufacturers part and by an Authorized

dealer or similarly qualified person.

FOCUS SUDS MAINTENANCE

Do not use water in the solution tank above 80°C

Use only water or neutral chemicals in the solution

tank. Do not use alkaline chemicals in the solution

tank.

At the end of each shift empty the cleaning solution

from the tank. Flush clean water through the tank

and solenoid valve to remove residual chemicals.

Pic 21 Transporting the Machine.

Pic 22 Cleaning and Checking the

Cord