Engine oil filter

Replace oil filter together with the oil

after every 150 hours of operation.

Note :

after having started engine,

check oil system for leaks.

Fuel system

The fuel tank is located behind the

cabin, on the left. The filler neck is

accessible and can be locked by key.

Stop engine before refueling and

remove ignition key. Never fill fuel in

indoor locations, remove spilled

fuel with a cloth right away. Avoid

smoking or handling open flames

when refueling or working in the

vicinity of the fuel system.

Fill with Diesel fuel CZ 51min. accor-

ding to EN 590.

Fuel capacity is 52 litres.

Note:

for more information about fuel,

in particular under the aspect of winter

service, refer to the VW Owner's

Manual. The fuel line from the tank

holds a fuel strainer that has to be

changed after first 300 hours of opera-

tion but at least after 600 hours of

operation.

When filling oil, avoid spilling over hot

engine - fire hazard.

Fill engine oil

Unscrew filler cap on cylinder head, fill

oil, check level on dipstick.

Note :

avoid oil level above max.

mark.

Change oil

Engine oil has to be changed after

every 150 hours of operation; make

sure engine is warm.

Drain plug is located on the left end

of the sump. To get access remove

bottom fairing under engine compart-

ment. Collect oil and dispose of in

accordance with current requirements.

Filler neck is located in the valve cap.

Engine oil: SAE 5-W40, SAE 10-W40,

SAE 15-W40 (equals VW spec. 50500

or 50501). Fill 4.5 litres. Check oil

level.

61

Air cleaner

Note:

We cannot give a warranty for

cleaned air cleaner cartridges.

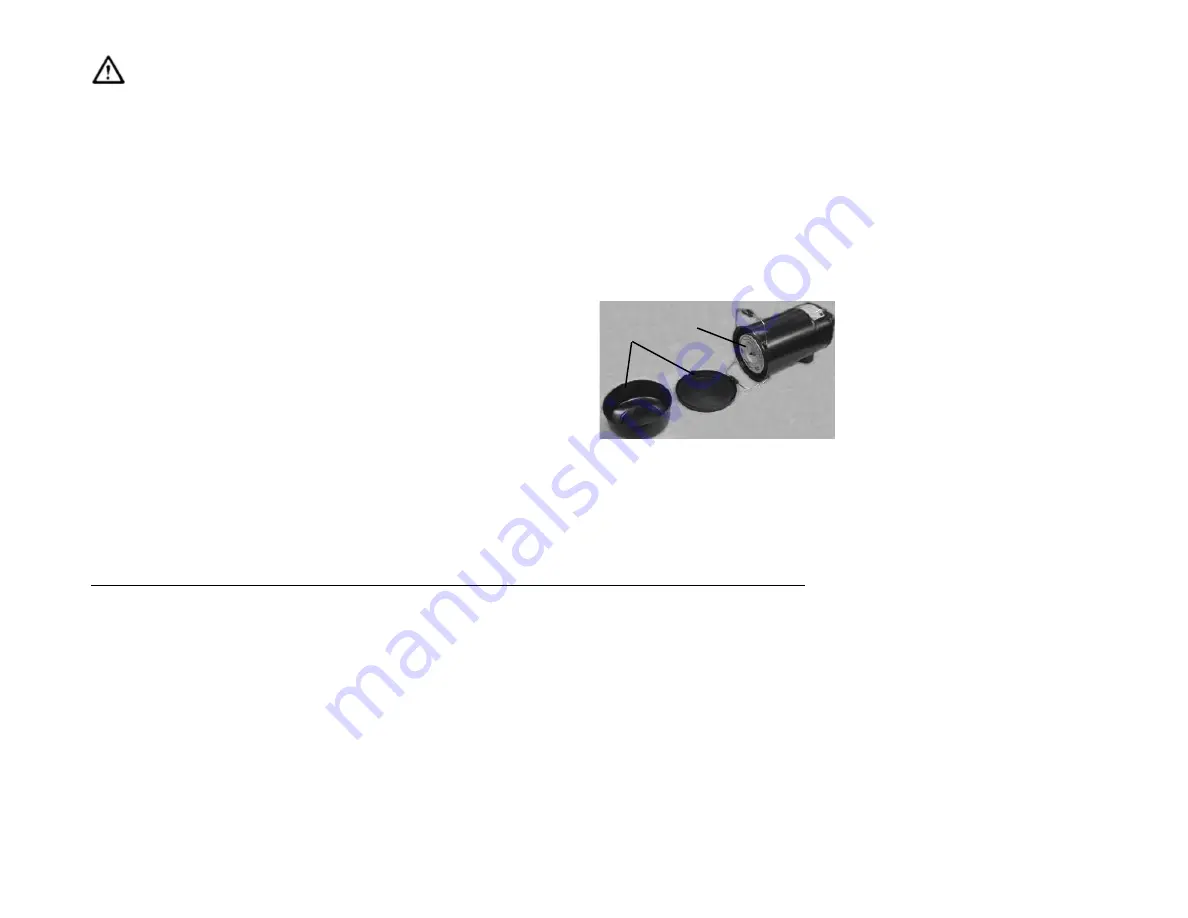

With its filtering cartridge, the air clea-

ner uses a separator (Fig. A/1) which

considerably extends the service life of

the cleaner element (Fig. A/2). Check

this separator for soiling weekly and

clean if required. The cleaner cartridge

has to be replaced e.g. if the indicator

lights permanently but at least after

600 hours of operation.

Note:

do not clean or replace the clea-

ner cartridge with the engine running.

1

2

A