24

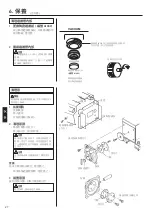

使用後的保養

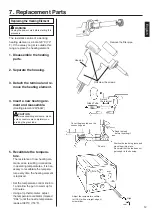

使用 HAKKO 474 吸錫槍後 , 應依照右列程

序進行保養 , 以確保經久耐用。

B. 吸力減弱

. 更換過濾器 , 清理吸嘴及發熱元件內部。( 參照第 25_26 頁 , 吸錫槍和機

身維修 )

●真空系統漏氣

指示燈不能表示漏氣情況。

檢查下列部件的密封空氣 , 如有損壞便應該更換 :

排除故障指南

警告

如果電源線損壞 , 應請製造商 , 或其代理商 , 或合格人士更換 , 以

免發生傷人或損壞機身事故。

● 電源指示燈不亮 ?

. 電源線是否插妥 ?

將插座插緊電源。

. 保險絲是否熔斷 ?

檢查出保險絲熔斷的原因 , 排除故障 , 並更換新保險絲。

例如

吸錫槍內部是否短絡 ?

● 泵不能操作

. 電線組件是否妥當接通 ?

重新接通電線組件。( 參閱第 20 頁 )

. 吸嘴或發熱元件內部的孔徑是否阻塞 ?

必須清理。(參閱第 25 頁 )

● 不能吸錫

. 彈簧過濾管是否充塞焊錫 ?

更換新彈簧過濾管。( 參閱第 26 頁 )

. 陶瓷過濾紙是否硬化 ?

更換新陶瓷過濾紙。

. 真空艙是否裂漏 ?

檢查連接部份 , 更換任何損壞部件。( 參閱第 24 頁 )

● 吸嘴不熱

. 吸錫槍的電線組件是否連接妥當 ?

重新連接。( 參閱第 20 頁 )

. 發熱元件是否損壞 ?

更換新發熱元件。( 參閱第 28 頁 )

註

交付修理時 , 請將吸錫槍和控制臺一起交給銷售商檢修。

a. 吸嘴接觸點和發熱元件

b. 過濾管前端蓋及其周圍部件

c. 後握器的圓環

d. 軟管

e. 真空出口蓋

f. 連接電線裝配及其周圍部件

.清除吸嘴內和發熱元件的焊錫。

.用清潔海綿清理吸嘴後 , 在吸嘴頭鍍上一層新焊錫 , 以保護鍍吸層。

中 文

Summary of Contents for 474

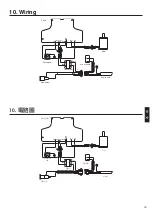

Page 19: ...3 18 1 2 M4 25 380 480 HAKKO...

Page 21: ...20 5 B1094 B1095 HAKKO 474 1 M4 25 2 3 4 IRON VACUUM...

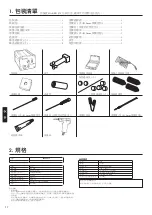

Page 22: ...21 1 2 1 2 5 6 3 5 3 1 HAKKO 191 HAKKO 192 HAKKO 474 380 480 1 2 3 4 5 6...

Page 23: ...22 2 3 4 5...

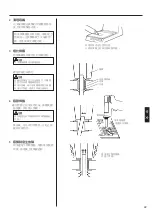

Page 24: ...23 1 HAKKO 475 HAKKO 475 HAKKO 475 2 1 3 3 2 1 A B A 70 80 25 25 5 25...

Page 25: ...24 HAKKO 474 B 25_26 20 25 26 24 20 28 a b c d e f...

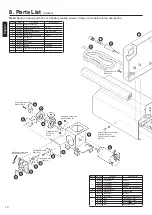

Page 26: ...6 25 HAKKO 474 1 2 3...

Page 27: ...26 6 A1033 A1033 4 A1033 5...

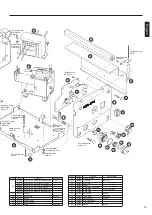

Page 28: ...27 1 A1009 2 1 2 3 A1009 S20 6 VACUUM...

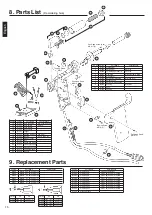

Page 29: ...28 7 23 2 4 1 2 3 4 24V 50W 5 1 3 CAL 380 CAL...