26

Operation

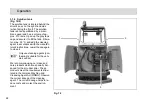

3.1.4

Solution tank

The solution tank is located behind the

driver's seat, on the right-hand side

(when facing the front). The solution

tank is a tank partitioned by a mem-

brane panel and has a volume of ap-

prox. 310 liters. Open up the gray tank

cap and secure it to fill the tank. Fill wa-

ter, max. 50 °C, and add the cleaning

agent in accordance with the manufac-

turer's instructions. Lower the cap again

to close it.

Only use cleaning agents (non-

foaming) suitable for the vehi-

cle's vendor.

We recommend using our clean and

care products which are specially bal-

anced for the scrubber drier. These

products meet the requirements stipu-

lated in the German Washing and

Cleansing Agent Act (WRMG). Observe

the correct dosage of the cleaning

agent. The correct dosage helps to re-

duce costs and protect the environ-

ment.

Fig. 12

3

1

2