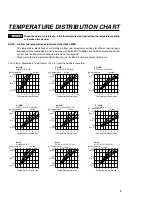

CAUTION

HOT

PREPARATION: ASSEMBLY AND ELECTRICAL CONNECTION

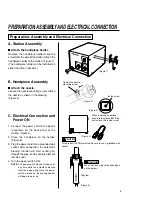

Preparation: Assembly and Electrical Connection

A. Station Assembly

●

●

●

●

●

Attach the handpiece holder.

Remove the handpiece holder mounting

screw from the side of the station. Attach the

handpiece holder to the station. (Figure 1)

(The handpiece holder can be installed on

either the left or right side.)

B. Handpiece Assembly

●

●

●

●

●

Attach the nozzle.

Loosen the nozzle mounting screw. Attach

the nozzle as shown in the drawing.

(Figure 2)

C. Electrical Connection and

Power ON

1. Connect the power cord to the power

receptacle on the back panel of the

station. (Figure 4)

2. Place the handpiece on the holder.

(Figure 5)

3. Plug the power cord into a grounded wall

socket. After connection, the automatic

blowing function will start sending air

through the pipe, but the heating element

remains cool.

4. Turn the power switch ON.

NOTE:

The power switch may be turned on at

any time while the automatic blowing

function is operating. Once the power

switch is turned on, the heating element

will begin to warm up.

Tighten the nozzle

mounting screw.

(Figure 1)

(Figure 2)

(Figure 3)

Inside screw

(Figure 4)

When installing an optional

nozzle to the Hakko 850B, do

not remove this inside screw.

CAUTION

This product is ESD-protected. Be sure to use a grounded wall

socket.

Top View

(Figure 5)

CAUTION

When not in use, place the handpiece

on the holder.

4

Summary of Contents for 850B

Page 15: ......