* Measure when the heating element is at room temperature.

Resistance value of heating

element (RED)

Resistance value of sensor

(BLUE)

2.5 – 3.5

43 – 58

Resistance value

of heating element

Resistance value

of sensor

If the resistance value is not normal, replace the heating

element.

(Refer to the instructions included with the replacement part.)

After replacing the heating element,

1. Measure the resistance value between pins 4 & 1 and 4 & 2, and

pins 5 & 1 and 5 & 2. If the resistance value is not infinite for all four

measurements, the heating element and sensor leads are

touching. This will damage the P.W.B. When reassembling, be

sure that the heating element and sensor leads do not touch.

2. Measure the resistance value ‘a’ ‘b’ ‘c’ to confirm that the leads are

not twisted and that the grounding spring is properly connected.

CAUTION

When reassembling, match the

convex part of the hexagon nut to

concave part of the housing.

Broken soldering gun cord

There are two methods of testing the soldering gun cord.

CAUTION

The LED heater lamp will flicker even with a normal gun cord if the temperature

reaches 480

C (896

F).

1. Turn the unit on and set the temperature to 480

C (896

F). Then

wiggle and kink the gun cord at various locations along its length,

including strain relief area. If the LED heater lamp flickers, then the

cord needs to be replaced.

2. Check the resistance value between the pin of the plug and the

wire on the terminal.

Pin 1: Red Pin 2: Blue Pin 3: Green Pin 4: White Pin 5: Black

The value should be 0

.

If it is greater than 0

or is infinite, the cord should be replaced.

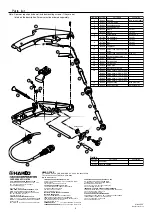

Parts list (Tips)

0

C

3

0.5(0.02)

900M-T-1.6D

0

C

5

0.5(0.02)

900M-T-2.4D

6.5

0.5(0.02)

900M-T-3.2D

0

C

951

900M-T-SB

0

C

900M-T-0.8C

-10

C/-18

F

900M-T-2C/900M-T-2CF*

0

C

900M-T-3C/900M-T-3CF*

0

C

900M-T-S4

0

C

900M-T-S10*

0

C

900M-T-S11*

0

C

951 tip out diam. ø6.5mm

• For heavy duty soldering Hakko recommends the 952 gun with heavier tips.

952

900L-T-B

0

C

900L-T-2B

0

C

0

C

900L-T-2.4D

900L-T-3.2D

0

C

-20

C/-36

F

900L-T-2C/900L-T-2CF*

0

C

900L-T-3C/900L-T-3CF*

900L-T-4C/900L-T-4CF*

0

C

900L-T-5C/900L-T-5CF*

0

C

900L-T-K

+20

C/+36

F

CAUTION

Use only genuine replacement tips for Hakko 951,952. The tips for Hakko Dash are not available to use.

These tips are tinned flat only.

952 tip out diam. ø8.5mm

(0.12)

ø

3.2

(0.09)

ø

2.4

(0.06)

ø

1.6

(0.25)

17(0.66)

17(0.66)

17(0.66)

(0.2)

(0.1)

14(0.55)

R0.2(0.008)

(0.08)

ø

2

900M-T-B/900M-T-BF2*

0

C

*BF2 is tinned a distance of 2mm (0.08 in.) from the end of the tip.

17(0.66)

R0.5(0.02)

17(0.66)

(0.031)

ø

0.8

45

17(0.66)

(0.08)

ø

2

45

17(0.66)

(0.1)

ø

3

45

900M-T-4C/900M-T-4CF*

0

C

17(0.66)

(0.16)

ø

4

45

15(0.6)

R0.25(0.01)

(0.08)

ø

2

17(0.66)

(0.1)

ø

3

55

17(0.66)

(0.16)

ø

4

55

20(0.79)

R0.5(0.02)

20(0.79)

R1(0.04)

20(0.79)

(0.09)

ø

2.4

5(0.2)

0.5(0.02)

20(0.79)

(0.12)

ø

3.2

8(0.32)

0.5(0.02)

20(0.79)

(0.08)

ø

2

45

20(0.79)

(0.1)

ø

3

45

20(0.79)

(0.16)

ø

4

45

15(0.6)

(0.2)

ø

5

45

18(0.71)

(0.2)

ø

5

2(0.08)

45

15(0.6)

900M-T-K

45

+30

C/+54

F

(0.2)

ø

5

2(0.08)

The tip temperature will vary according to the shape of the tip. The preferred

method of adjustment uses a tip thermometer. (Refer to the instruction manual

for the station.) A less accurate method involves adjusting the temperature

settings according to the adjustment value for each tips.

Examples: When using a 900M-T-0.8C tip at 400

C (750

F), the

difference between this tip and standard tip is –10

C (–18

F).

Set the temperature to 410

C (768

F).

Refer to the chart for the correct adjustment values.

3

Hexagon nut M4