23

Operation

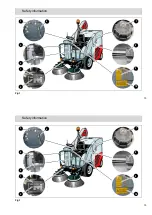

3.1.2 Solution system

The solution system is comprised of a

tank, pump, valve and spray jets. The

solution tank (Fig. 6/1) is located to the

left of the driver's seat and has a

volume of 100 liters. An electrical pump

feeds the solution to the spray jets. The

spray jets are arranged at the front on

the circular brush frame so that the jet

for solution sprays in front of the

brushes binding the dust and wetting

the surface prior to being cleaned by

the brushes. There is another spray jet

located in front of the fan. If the metal

filter option is installed, there is a spray

jet on the vacuum nozzle.

3.1.3 Sweepings container

The waste is vacuumed up by means of

the suction turbine (Fig. 6/2) and forced

into the sweepings container (Fig. 6/3).

To bind the dust optimally, solution from

the solution system is also supplied to

the vacuum nozzle.

Fig.6

2

1

3

23

Operation

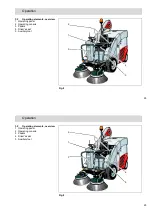

3.1.2 Solution system

The solution system is comprised of a

tank, pump, valve and spray jets. The

solution tank (Fig. 6/1) is located to the

left of the driver's seat and has a

volume of 100 liters. An electrical pump

feeds the solution to the spray jets. The

spray jets are arranged at the front on

the circular brush frame so that the jet

for solution sprays in front of the

brushes binding the dust and wetting

the surface prior to being cleaned by

the brushes. There is another spray jet

located in front of the fan. If the metal

filter option is installed, there is a spray

jet on the vacuum nozzle.

3.1.3 Sweepings container

The waste is vacuumed up by means of

the suction turbine (Fig. 6/2) and forced

into the sweepings container (Fig. 6/3).

To bind the dust optimally, solution from

the solution system is also supplied to

the vacuum nozzle.

Fig.6

2

1

3