63

Maintenance and Care

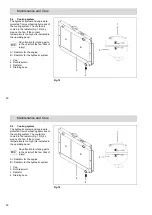

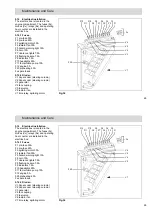

5.10.1 Cleaning the fine particle filter

Check the coarse particle sieve and

filter hoses daily for accumulations of

dirt, clean as necessary.

1. Switch the suction turbine off.

2. Agitate the filter system. Actuate the

agitating device (automatic agitating

time approx. 20 sec.) several times,

if necessary.

3. Open the fastening device (Fig. 27/

2). Pull out the pivoting lever (Fig. 27/

3) and pivot the filter case (Fig. 27/1)

to the rear. Dry clean the filter hoses

(Fig. 27/6).

4. Pivot the filter case downwards so

that the loose dirt can slide out. If

necessary, switch on the agitating

device.

Do not use liquids to clean the

filter hoses, simply beat clean

or use compressed air.

5. Remove the coarse particle sieve

(Fig. 28/1) and clean it. Reinsert the

coarse particle sieve, pivot the filter

case back in place and close it

properly.

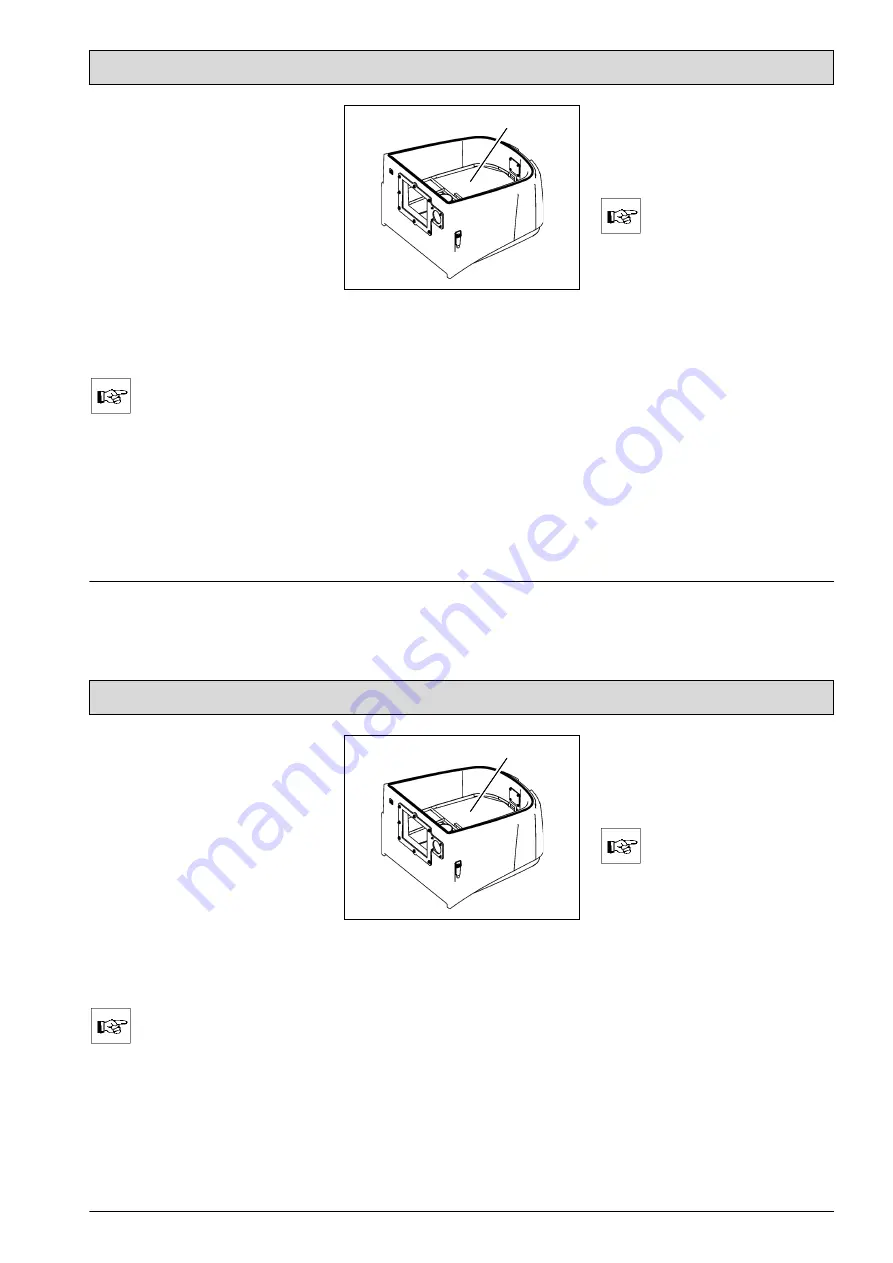

Fig.28

1 Coarse particle sieve

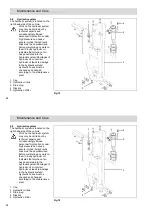

5.10.2 Changing the fine particle

filter

Check the filter hoses every 250

operating hours for signs of wear,

replace if necessary.

1. Open the fastening device (Fig. 27/

2) and pivot the filter case (Fig. 27/1)

out towards the rear.

2. Remove the screws at the corners.

3. Raise the filter package slightly and

unplug the cable in the agitating

motor.

4. Remove the filter package fully.

5. Remove the filter hoses from the

perforated metal plate.

6. Clean the perforated metal plate

(Fig. 27/7) thoroughly, insert new

filter hoses and press on evenly.

Before inserting the new filter

hoses, we recommend heating

the clamping piece a little using

hot air or hot water.

Installation is carried out in the reverse

sequence.

1

63

Maintenance and Care

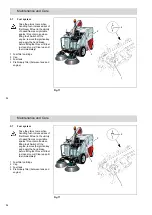

5.10.1 Cleaning the fine particle filter

Check the coarse particle sieve and

filter hoses daily for accumulations of

dirt, clean as necessary.

1. Switch the suction turbine off.

2. Agitate the filter system. Actuate the

agitating device (automatic agitating

time approx. 20 sec.) several times,

if necessary.

3. Open the fastening device (Fig. 27/

2). Pull out the pivoting lever (Fig. 27/

3) and pivot the filter case (Fig. 27/1)

to the rear. Dry clean the filter hoses

(Fig. 27/6).

4. Pivot the filter case downwards so

that the loose dirt can slide out. If

necessary, switch on the agitating

device.

Do not use liquids to clean the

filter hoses, simply beat clean

or use compressed air.

5. Remove the coarse particle sieve

(Fig. 28/1) and clean it. Reinsert the

coarse particle sieve, pivot the filter

case back in place and close it

properly.

Fig.28

1 Coarse particle sieve

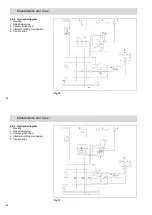

5.10.2 Changing the fine particle

filter

Check the filter hoses every 250

operating hours for signs of wear,

replace if necessary.

1. Open the fastening device (Fig. 27/

2) and pivot the filter case (Fig. 27/1)

out towards the rear.

2. Remove the screws at the corners.

3. Raise the filter package slightly and

unplug the cable in the agitating

motor.

4. Remove the filter package fully.

5. Remove the filter hoses from the

perforated metal plate.

6. Clean the perforated metal plate

(Fig. 27/7) thoroughly, insert new

filter hoses and press on evenly.

Before inserting the new filter

hoses, we recommend heating

the clamping piece a little using

hot air or hot water.

Installation is carried out in the reverse

sequence.

1