4. Operation

(cont'd)

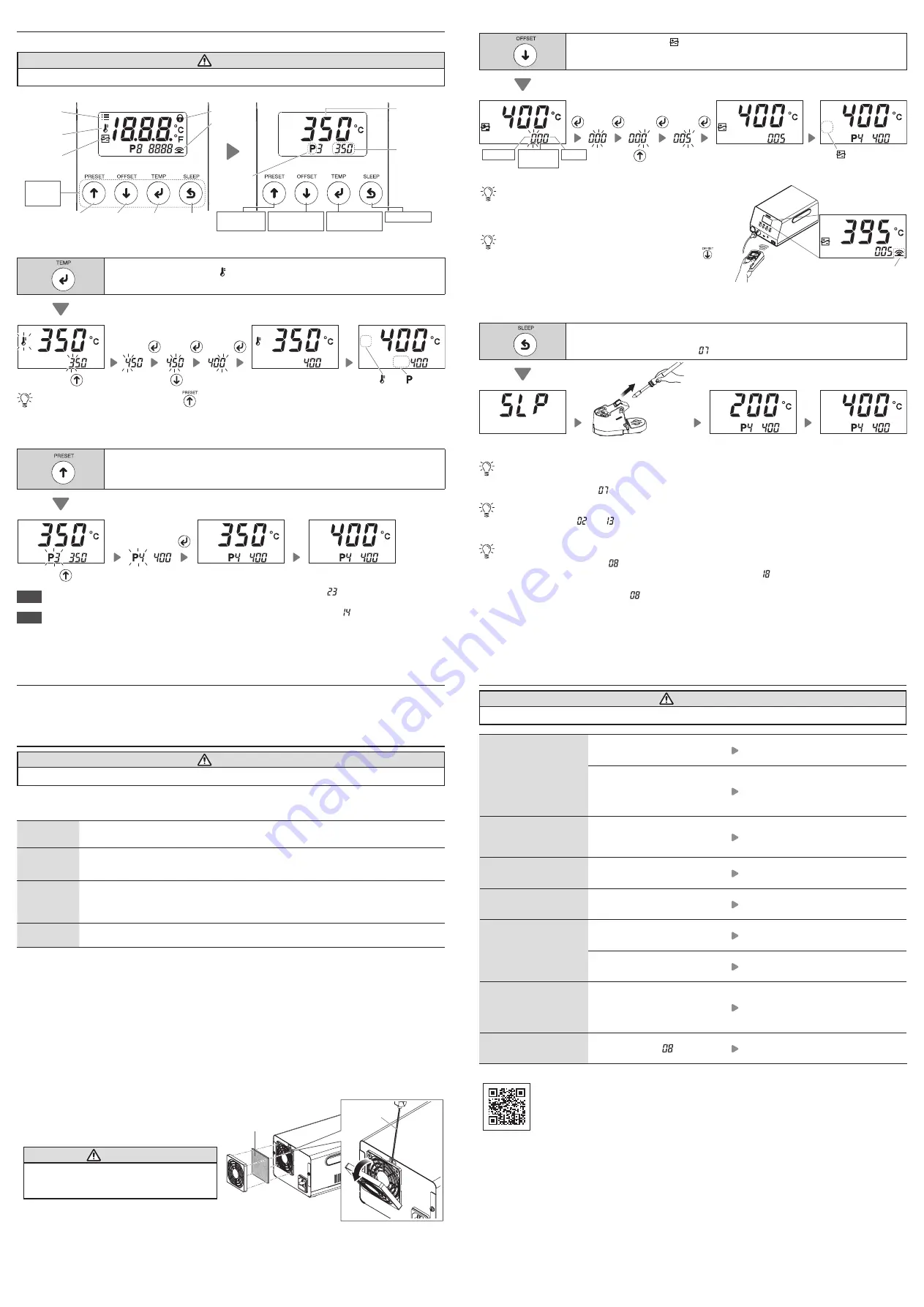

4-3. Operation

CAUTION

Place the handpiece into the iron holder and then turn on the power.

The following display appears after turning the power on.

Lock icon

Temperature

icon

Offset icon

Operation

button

Communication

icon

Setting

temperature

Temperature

Correction Mode

Temperature

Setting Mode

Preset icon

Sleep Mode

Back

button

Confirm

button

Down

button

Up

button

Parameter

icon

Tip sensor

temperature

Preset No.

Mode

■

Changing the temperature setting

Push

Push this button once to display [ ] and transition to "temperature setting mode."

This mode is used when changing the set temperature.

Push

once

[ ] and [

]

disappear.

Temperature

control begins

Normal screen

To change to 400ºC

Push

five times

Push

Push

Push

Once the normal screen appears, push the

button to transition to preset No. mode.

■

Changing the preset No.

You can register up to five frequently used setting temperatures on the product, and then select the registration No. to change

the setting temperature.

Push

Push this button once to transition to "preset No. mode."

Select one of the five temperatures registered in this mode.

( Factory default temperature settings: P1 250ºC (600ºF), P2 300ºC (700ºF), P3 350ºC (750ºF),

P4 400ºC (800ºF), P5 450ºC (850ºF))

Push

once

Temperature

control begins

Normal screen

To change to P4 (400ºC)

Push

NOTE

The registered temperature of each preset No. can be changed in "parameter No.

."

(See the separate document "Quick Parameter Settings")

NOTE

If you want to limit setting temperature changes, change the setting in "parameter No.

."

(See the separate document "Quick Parameter Settings")

■

Tip temperature correction (offset)

Push

Push this button once to display [

] and transition to "temperature correction mode." If the setting

temperature and the measured value of the tip temperature differ in this mode, you can correct the temperature.

(Correction range:

±

50ºC/

±

90ºF)

Push

five times

Temperature

control begins [

] disappears.

Normal screen

To correct a temperature by 5ºC for a setting of 400ºC (to correct

actual tip measurement reading 395ºC when set to 400ºC)

0 to 5

(ºF: 0 to 9)

0 to 9

Push

Push

Push

Push

–/0

*Note that temperatures that exceed the correction range cannot be entered.

Once a tip degrades from wear, the tip temperature tends to drop.

The tip temperature changes if you replace the tip, the offset will

need to be readjusted. Make sure to change the offset value as

needed while monitoring the actual tip temperature.

You can automatically change the offset value using a HAKKO

thermometer with a temperature sending function. Push the

b

utton before sending the measured value. (See the figure on the

right)

FX-805

Temperature sending

screen

The communication icon is

only displayed at this state.

■

Pausing work (sleep mode)

Push

Push this button once to immediately transition to "sleep mode (state where the tip temperature has

dropped to the set activation temperature)." Use this function occasionally to prevent tip oxidation.

(Factory default setting: Parameter No.

setting is enabled and the activation temperature is 200ºC)

Temperature control

begins

Normal screen

Transition to normal mode

・

Lift the handpiece from the iron holder.

・

Push any of the operation buttons.

The product will not transition to sleep mode in the following cases:

・

When the setting temperature is lower than 300ºC (580ºF)

・

When the parameter No. setting is disabled

Approximately six minutes after placing the handpiece on the iron holder, the product automatically transitions to sleep mode.

Change parameter No. and settings as necessary for your work. (See the separate document "Quick Parameter

Settings")

To further prevent tip oxidation, set auto shut-off.

(1) Enable the parameter No. setting.

(2)

Set the time until the product is automatically shut-off in parameter No.

.

The shorter the set time, the more effective it is.

If you disable the parameter No.

setting, the product will not automatically shut-off even when the set time has

elapsed.

5. Parameter Settings

You can change the parameter settings to suit different work environments. See the separate document

"Quick Parameter Settings."

6. Maintenance

CAUTION

Do not file oxidation attached on the tip. This will shorten the tip lifespan.

Conducting maintenance will help keep the product in good condition and prolong the usage of the unit.

■

Daily maintenance

Setting

temperature

Using the product at a temperature that is higher than necessary can accelerate tip deterioration

and damage parts that are susceptible to heat. Use the lowest temperature whenever possible.

Before

beginning work

Perform a visual check of the tip. Replace it if it is bent or considerably worn. Use the cleaning

sponge to wipe off any oxidation or old solder from the tip. Impurities on a circuit board can result

in poor soldering.

When pausing

work

Use sleep mode instead of leaving the handpiece set to a high temperature for a long period of

time. This prevents tip oxidation which helps to maintain workability, which can extend the tip

lifetime. Turn off the power switch when not using the product for a long period of time.

(See "

■

Pausing work (sleep mode)")

After finishing

work

Thoroughly clean the tip with the cleaning sponge and then coat it with new solder. Doing so can

prevent oxidation of the tip.

■

Periodic maintenance

●

Tip

Wear and tear on the tip will vary due to the operating temperature as well as the quality and amount of

solder/flux used. Maintenance should be performed based on what suits your usage.

(1) Turn the power ON.

(2) Set the temperature to 250ºC (482ºF).

(3) Once the temperature is stable, use the cleaning sponge to wipe the tip.

(4)

If there is any black oxidation on the solder plating, apply new solder containing flux and then wipe it off

with the cleaning sponge. Repeat this process until the oxidation is removed. Afterward, coat it with new

solder.

(5)

Turn the power off and remove the tip once it has cooled.

If you find flux, debris, and other particulates on anything other than the end of the tip, wipe it off with

industrial alcohol.

●

Air inlet filter

Check the air inlet filter to make sure it is not

clogged.

Clogging can cause the internal temperature of

the station to rise, resulting in malfunction.

CAUTION

When replacing the filter, turn off the power

switch and disconnect plug from the power

outlet.

●

Handpiece

Remove flux, debris, and other particulates adhering to the nipple.

It may cause contact failure inside the handpiece.

●

Iron holder

・

Press down the release button and remove the iron holder base, then clean the collected solder waste

from the iron holder.

・

Rotate the cleaning wire as need to a clean side where solder is not accumulated.

Screwdriver

Filter

7. Troubleshooting

CAUTION

Before performing an inspection or replacing parts, make sure to disconnect the power plug from the outlet.

No operation even if

power switch is turned

ON.

Has the power cord or

connection plug been removed?

Plug unit into outlet.

Is the fuse blown?

Replace the fuse.

If the fuse is blown again, send the

main unit (including handpiece, power

cord) back for service.

[C - E] is displayed.

Is an incompatible soldering

iron connected? Or has the

handpiece plug been removed?

Turn off the power switch, reconnect

the handpiece, and turn the power

switch back on again.

[S - E] is displayed.

Is the tip fully inserted?

Insert tip firmly into the handpiece.

(do not use excessive force)

[t - E] is displayed.

Are you using a tip that is

applicable with this product?

If not, replace it with a T37 or T33 series

tip.

Cannot get solder on the

tip.

Is the tip setting temperature too

high or too low?

Set an appropriate temperature.

Is there any oxidation on the tip?

Remove the oxidation.

(See "6. Maintenance")

The tip temperature is

too high.

The tip temperature is

too low.

Is the offset value entered

correct?

Measure and adjust the value.

(See "

■

Tip temperature correction

(offset)" in "4-3. Operation")

The auto shut-off

function does not work.

Is parameter No. [OFF]?

Change it to [on] to enable feature.

For more support information, visit the website.

If you cannot find a solution in this manual or on the website, or if another problem occurs,

please contact the retailer where you purchased the product.

https://www.hakko.com/doc_fx805