2. Broken cord assembly

7. MAINTENANCE

Tip temperature

Cleaning

When not in use

After use

8. CHECK PROCEDURE

WARNING

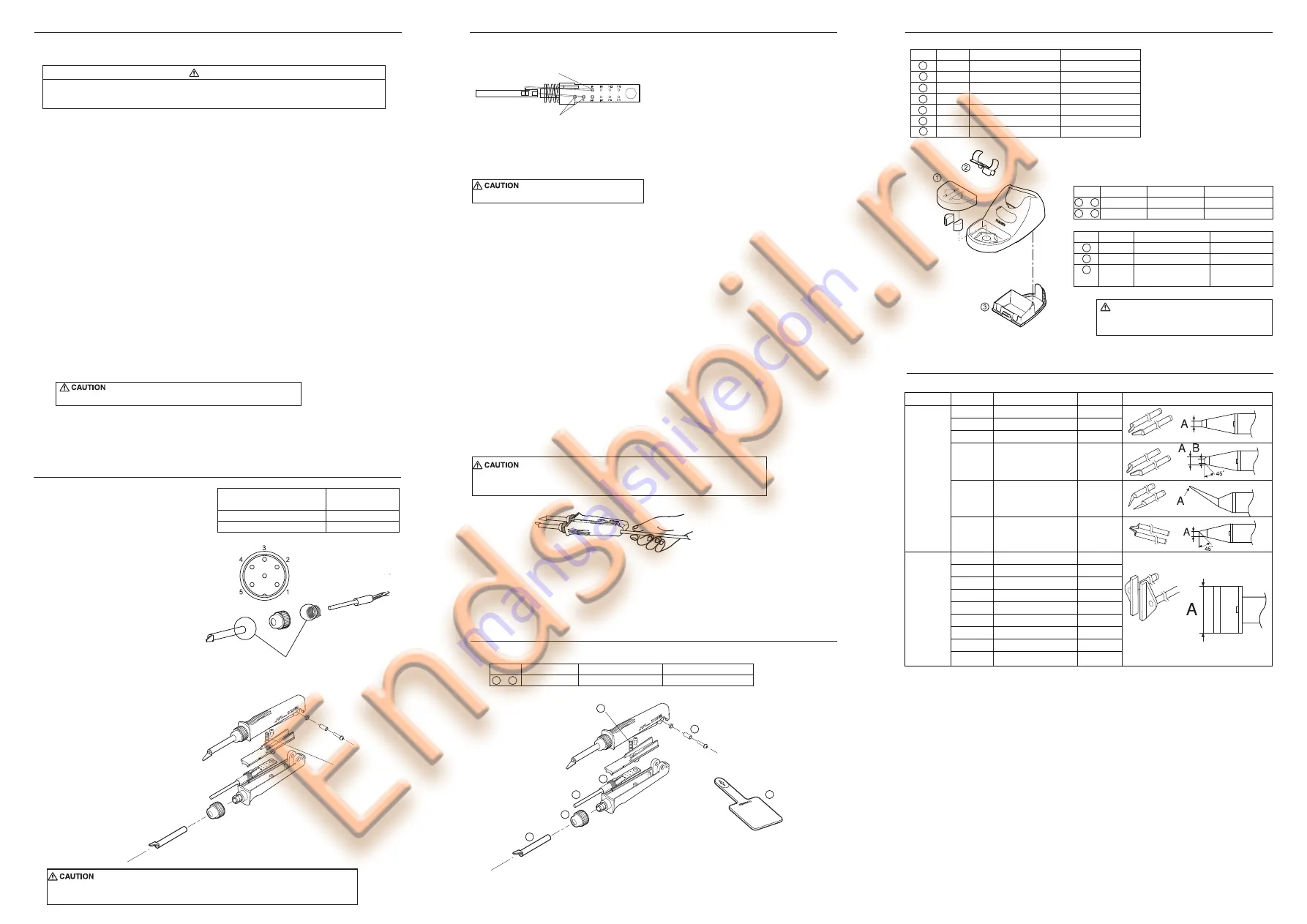

1. Broken heating element / sensor

Rub lightly with sand-paper or

steel wool.

Be sure to measure the resistance of the heating element in both handles A and B.

If one of the heating elements is broken, replace both heating elements.

Heating element (Red)

Sensor (Blue)

8. CHECK PROCEDURE

9. PARTS LIST

●

HAKKO FX-8804 Hot Tweezer

9. PARTS LIST

10. TIP STYLES

●

HAKKO FX-8804

A1577

A1379

A1378

A1388

A1389

A1576

A1390

A1391

A1380

A1381

A1382

A1392

A1383

A1384

A1385

Tip /CHIP 0.5L

Tip /CHIP 1L

Tip /CHIP 2L

Tip /CHIP 0.5C

Tip /CHIP 0.5I

Tip /CHIP 2.6C

Tip /SOP 4L

Tip /SOP 6L

Tip /SOP 8L

Tip /SOP 10L

Tip /SOP 13L

Tip /SOP 15L

Tip /SOP 18L

Tip /SOP 20L

Tip /SOP 25L

0.5 mm

1 mm

2 mm

1.5(0.5)

R0.25

2.6

4 mm

6 mm

8 mm

10 mm

13 mm

15 mm

18 mm

20 mm

25 mm

For

CHIP

For

SOP

Shape

Size A(B)

Performing proper and periodic maintenance extends product life and contributes to the

quality of soldering work. Efficient soldering depends upon the temperature, the quality and quantity of

the solder and flux. Apply the following service procedure as dictated by the conditions of the usage.

Since the tip can reach a very high temperature, please work carefully.

Except where indicated, always turn the power switch OFF and disconnect the power plug

before performing any maintenance procedure.

High temperatures shorten tip life and may cause thermal shock to components.

Always use the lowest possible temperature. The excellent thermal recovery characteristics

of the HAKKO FX-888D ensures effective soldering at low temperature.

Always clean the tip before use to remove any residual solder or flux adhering to it.

Use a cleaning sponge or the HAKKO 599B tip cleaner.

Contaminants on the tip may have negative effects, including reduced heat conductivity,

which contribute to poor performance.

Never allow the unit to idle at a high temperature for extended periods. This will allow the

tip to become oxidized. Turn the power switch OFF. If it is to be out of service for

several hours, it is advisable to disconnect the power plug as well.

Always clean the tip and coat it with fresh solder after use. This guards against oxidation.

1. Set the temperature to 250℃(482℉).

2. When the temperature stabilizes, clean the tip and

check the condition of the tip. If the tip is badly worn or deformed, replace it.

3. If the solder plated part of the tip is covered with black oxide, apply fresh solder,

containing flux, and clean the tip again. Repeat until all the oxide is removed,

then coat the tip with fresh solder.

4. Turn the power OFF and remove the tip, using the heat resistant pad. Set the tip aside to

cool.

Do not file the tip in an attempt to remove the black oxide.

Disconnect the plug of the cord assembly

and measure the resistance value

between the pin of the connecting plug as follows.

If the values of “a” and ”b” are outside

the value in the table, replace the heating

element(sensor) and/or cord assembly.

If the value of “c” is over the value in the

table, remove the oxidization film by lightly

rubbing with sand-paper or steel wool

the points shown in the drawing on the right.

●

●

Tip

Nipple

Handle A

Handle B

a. Between pins 4 & 5

(heating element)

b. Between pins 1 & 2 (Sensor)

c. Between pin 3 & tip

2.5 ~ 4.5 Ω

(at time of room temperature)

43 ~ 58 Ω

2 or less Ω

1. Loosen the nipple by turning it counterclockwise.

2. Pull out the tip.

3. Remove the screw and strut pin. Separate into handle A and B.

Remove the tension spring.

Do not lose the tension spring.

4. Remove each tapping screw of the handle A and B, and remove the handle cover.

5. Pull out the P.W.B. and heating element.

*Measure when the heating element is at room temperature.

1. Heating element resistance (red) 2.5-4.5 Ω

2. Sensor resistance (blue) 43-58 Ω

If the resistance value is not normal, replace the heating element.

(Refer to the instructions included with the replacement part.)

After replacement

1. Measure the resistance between pins 4 and 1, 4 and 2, 5 and 1, 5 and 2.

If it is not ∞, the heating element and sensor are touching. This will damage the circuit board.

2. Measure the resistance “a” , “b” and “c” to confirm that the leads are not twisted and that

the grounding spring is properly connected.

There are two methods of testing the cord assembly as below.

1. Turn the power on and set the temperature control knob to 400℃(752℉). Then, bend the cord

at various locations along its length, including in the strain relief area.

If the LED heater lamp flashes, then the cord needs to be replaced.

2. Check the resistance between the plug pin and the terminal lead.

Pin 1: Red Pin 2: Blue Pin 3 : Green

Pin 4 : White Pin 5 : Black

If it is higher than 0 Ω or ∞, the cord should be replaced.

The power lamp starts to flash when the temperature reaches 400℃(752℉)

regardless of the condition of the cord.

FX8804-02

HAKKO FX-8804

1

〜

6

AC26V 65W

Item No.

Part No.

Part Name

Specifications

Item No.

Part Name

Tip

Heating element

Nipple

Terminal

Tension spring

Strut pin

Heat resistant pad

A1578

B2289

B2290

B2295

B2296

B2300

1

2

3

4

5

6

7

Item No. Part No.

Part Name

Specifications

See”TIP STYLES”

2 PCS.

1

2

5

4

3

7

66

Nut

Strut pin

Screw

Tension spring

●

Tip Maintenance

●

Iron holder parts

●

HAKKO FH-800 Iron holder

Item No.

1

2

3

Item No.

1

〜

3

1

〜

3

Part No.

FH800-04BY

FH800-04SV

Part Name

HAKKO FH-800

HAKKO FH-800

Specifications

Blue-Yellow

Silver

Part No.

A1559

B3666

B3475

Part Name

Cleaning sponge

Holder clip

Bottom plate with

protection plate

Specifications

with Protective Sheet

& rubber foot

CAUTION

For safety reasons, please attach the protective sheet

to the bottom plate when using the HAKKO FX-8804.