11

4.1 Machine to the

employment prepare

When being supplied to you, the

Hakomatic is packed in a cardboard

box. The floor consists of a wooden

plat form where the machine is fixed

by means of plastic straps.

Open the box from its bottom side and

remove it by pulling upwards.

After detaching the plastic wraps, you

now can follow the below 4 instruc-

tions.

Important Note

Owner’s personnel is not allowed to

open the machine.

1

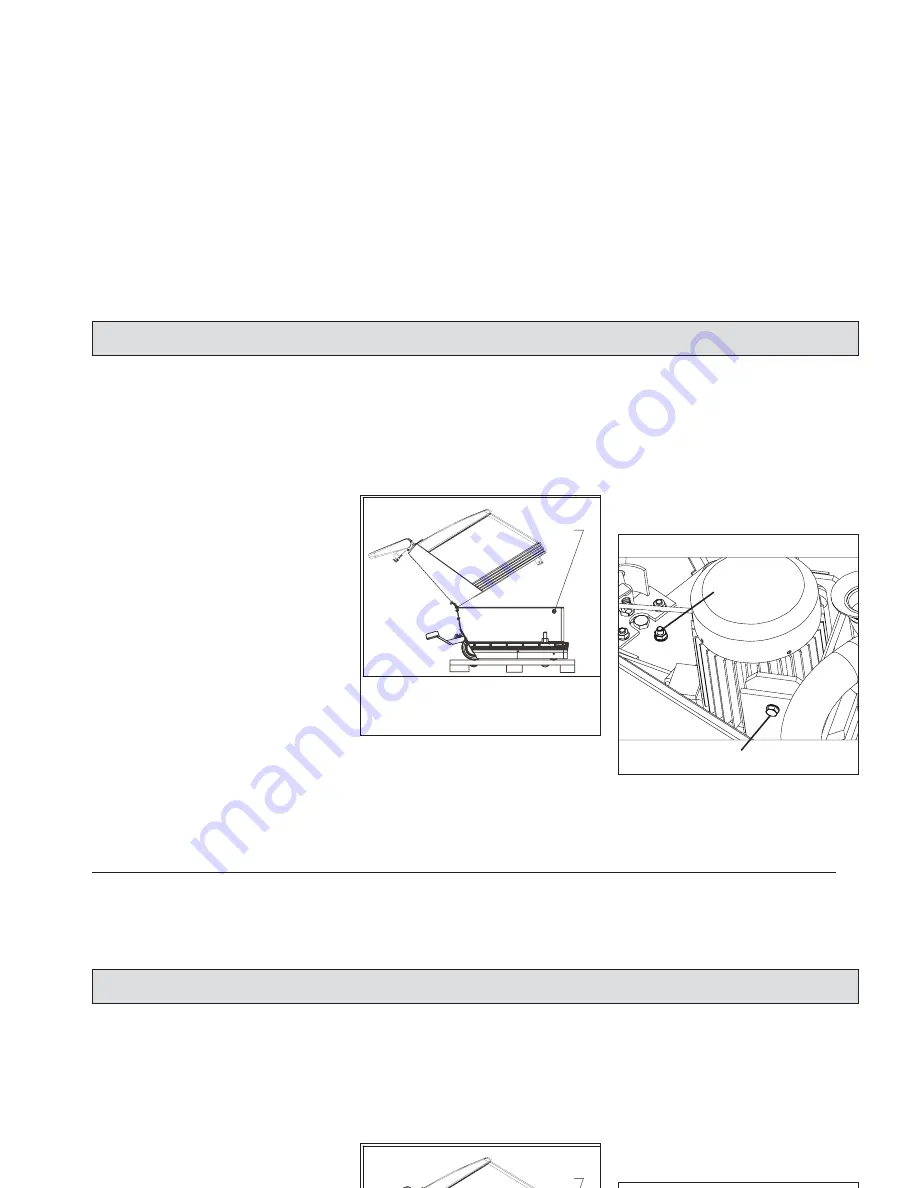

Tilt the body of the machine after re-

moving rubber caps & allen

screws(on both sides) in order to

Gain access to the inside of the ma-

chine.

2

The brush motor is fastened to its

guide ways by a screw in order to

prevent unwanted movement during

transport. Remove this screw and

check for the up-and-down move-

ment of brush motor. Also remove

the tie bolt indicated

4. Taking into operation

Rubber cap

& screw

Fig.8

Fig.9

Screw

Tie bolt

11

4.1 Machine to the

employment prepare

When being supplied to you, the

Hakomatic is packed in a cardboard

box. The floor consists of a wooden

plat form where the machine is fixed

by means of plastic straps.

Open the box from its bottom side and

remove it by pulling upwards.

After detaching the plastic wraps, you

now can follow the below 4 instruc-

tions.

Important Note

Owner’s personnel is not allowed to

open the machine.

1

Tilt the body of the machine after re-

moving rubber caps & allen

screws(on both sides) in order to

Gain access to the inside of the ma-

chine.

2

The brush motor is fastened to its

guide ways by a screw in order to

prevent unwanted movement during

transport. Remove this screw and

check for the up-and-down move-

ment of brush motor. Also remove

the tie bolt indicated

4. Taking into operation

Rubber cap

& screw

Fig.8

Fig.9

Screw

Tie bolt

Summary of Contents for Hakomatic E 430

Page 1: ...Instruction Manual Hakomatic E 430 7324 12...

Page 29: ......