Armadillo 6X and AM7D-III PB# 4100043UM Rev. B 07/20

PowerBoss®, Copyright 2014

Page 5

PowerBoss

®

The Power of Clean

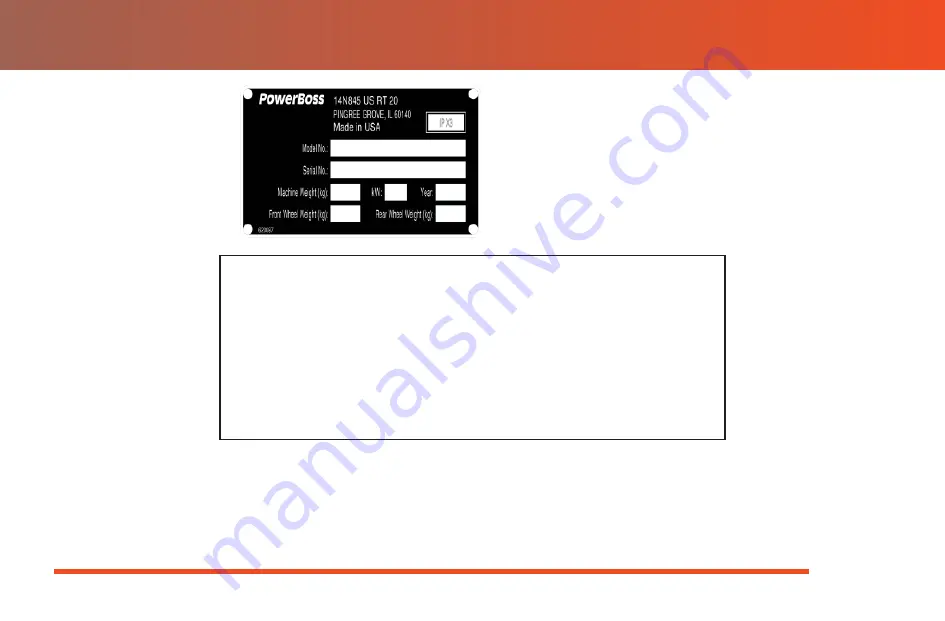

Example I.D Plate:

MACHINE DATA

Fill out at installation

Machine Serial Number: ____________________________

Engine Serial Number: ____________________________

Sales Rep.: ______________________________________

Date of Install: ___________________________________

All information contained in this manual is current at the time of printing. Minuteman International, Inc.

reserves the right to make changes at any time without notice.

PowerBoss®, Minuteman International, Inc., Printed in USA ©2014