Reviews:

No comments

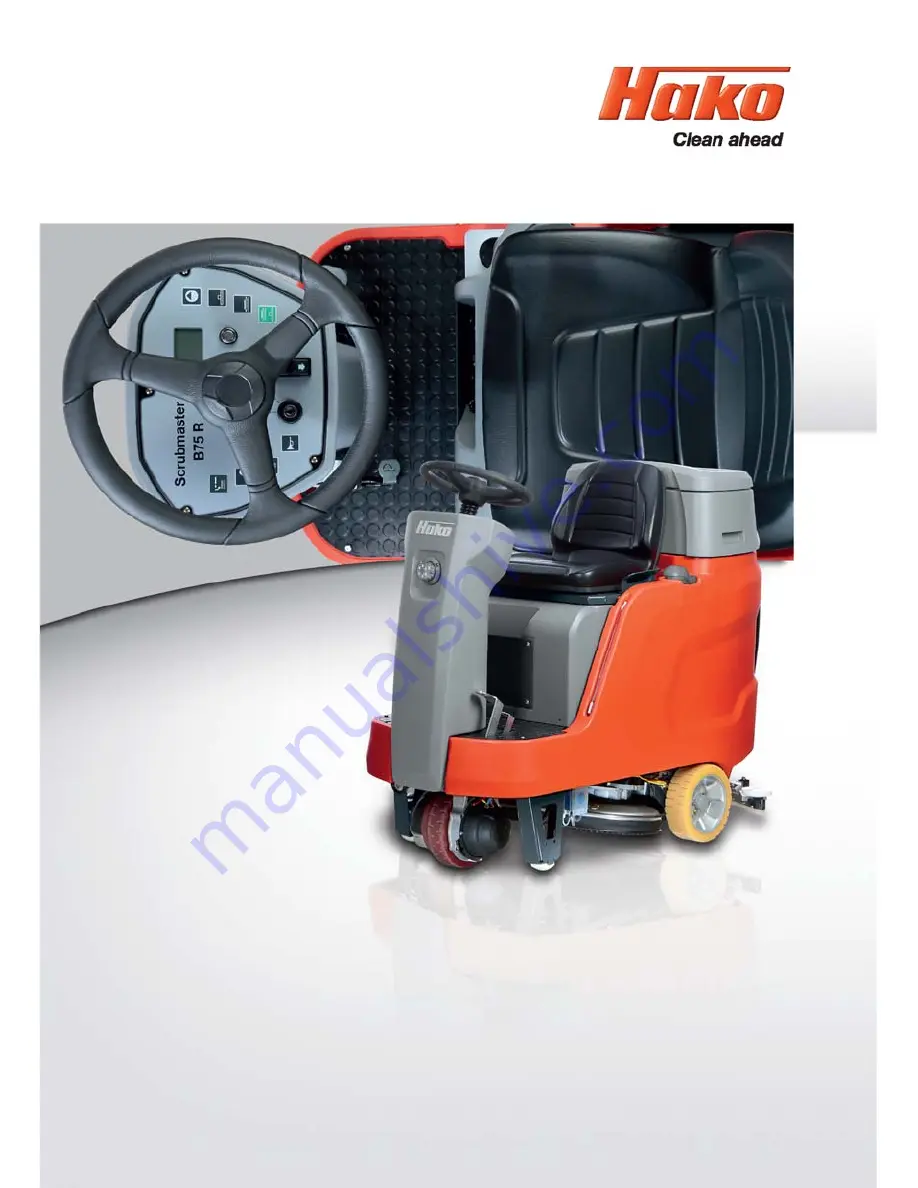

Related manuals for Scrubmaster B75R

PEX 500-C-TICK

Brand: U.S. Products Pages: 28

FANG 32T-EU

Brand: Viper Pages: 402

GT 25 Series

Brand: GADLEE Pages: 56

ICON 1002

Brand: RCm Pages: 126

ARM-EVAC 50

Brand: Pace Pages: 10

RT-50D

Brand: Sunmax Pages: 16

31 B 46

Brand: Gansow Pages: 78

I115SS

Brand: Clemas & Co Pages: 49

i-mop Lite

Brand: Clemas & Co Pages: 58

HC-2197

Brand: Mannol Pages: 15

EASY ARM 2

Brand: Kurtz Ersa Pages: 30

HA-CMSC-G2-W-AEA

Brand: HealthyAir Pages: 43

Boxxer H2O

Brand: HydraMaster Pages: 62

SC530 53 B GO

Brand: Crescent Pages: 47