51

Maintenance and Care

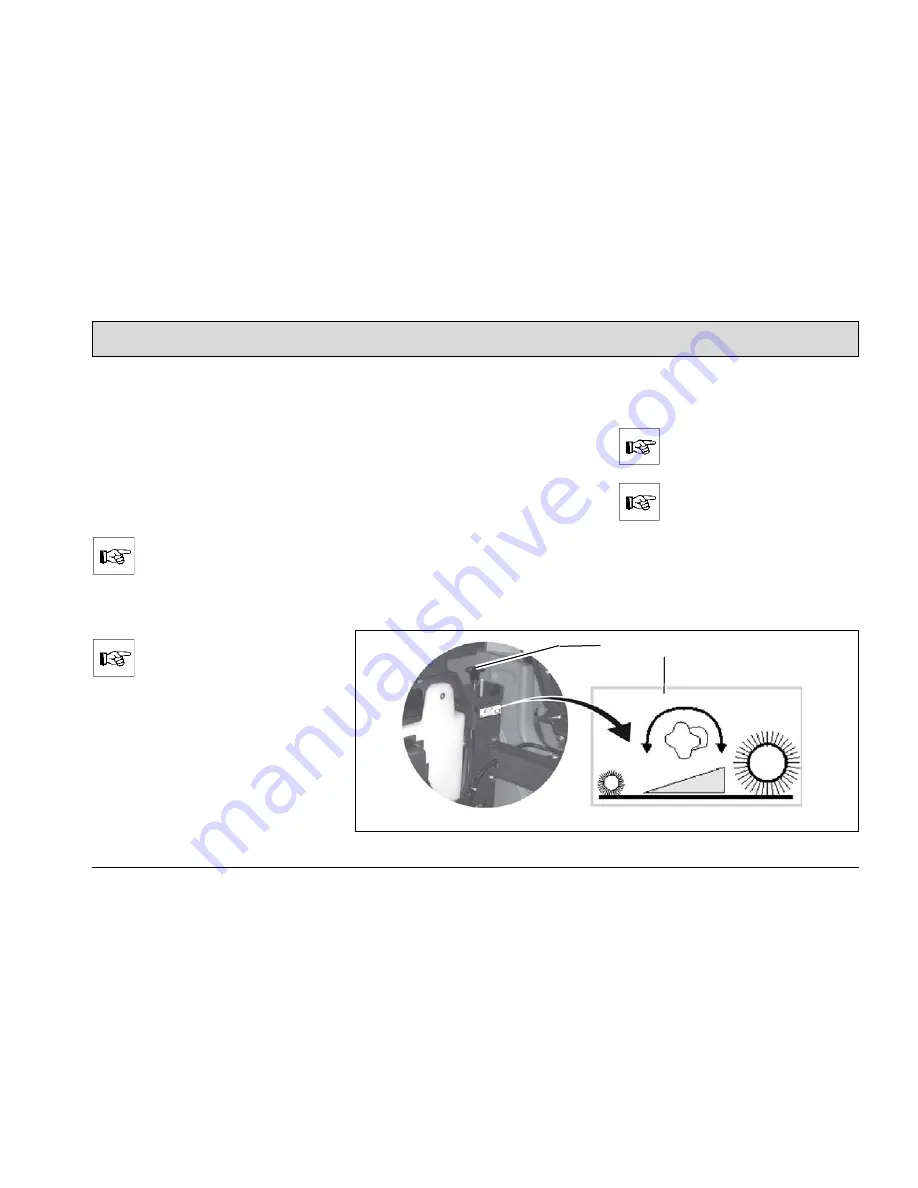

5.5.2 Adjust Sweeping Track

An adjustment device allows adaption

to different sweeping conditions. The

sweeper roller has to be adjusted for

normal use and with regard to a low de-

gree of wearing as described in the fol-

lowing.

Check the sweeper adjustment on level

ground as follows:

Before checking:

Mark level surface for checking

sweeper adjustment by chalk

(1000 x 300 mm).

Drive sweeping roller over un-

derline floorspace.

Check inflation pressure of

tyres (6bar).

Air tyres only.

• Secure machine by engaging park-

ing brake.

• Lower sweeper roller and let it run

dry.

• Lift sweeper roller and forward the

Sweepmaster B1200 RH a bit.

With the correct sweeper adjustment

the prallel sweeping marks have to

be appear on the floor (sweeping

track).

The sweeping track width is to be

70 mm with the Sweepmaster B1200

RH.

The sweeping track width can be ad-

justed at the star-shaped knob (Fig. 16/

1) as follows:

• Stop machine and pull key switch.

• Engage parking brake.

• Open seat hood.

• Turn star-shaped knob (Fig. 16/1)

to the left = wider sweeping tack

to the right = smaller sweeping track

(Sweeper adjustment sticker (Fig.

16/2)

Fig.16

• Check sweeping track

With one full turn of the knob,

the track widens or broadens

by approx. 10mm.

When exeeding the sweeping

tack width the sweeper roller

wearing increases as well as

the load of the drive.

2

1