8

Controls

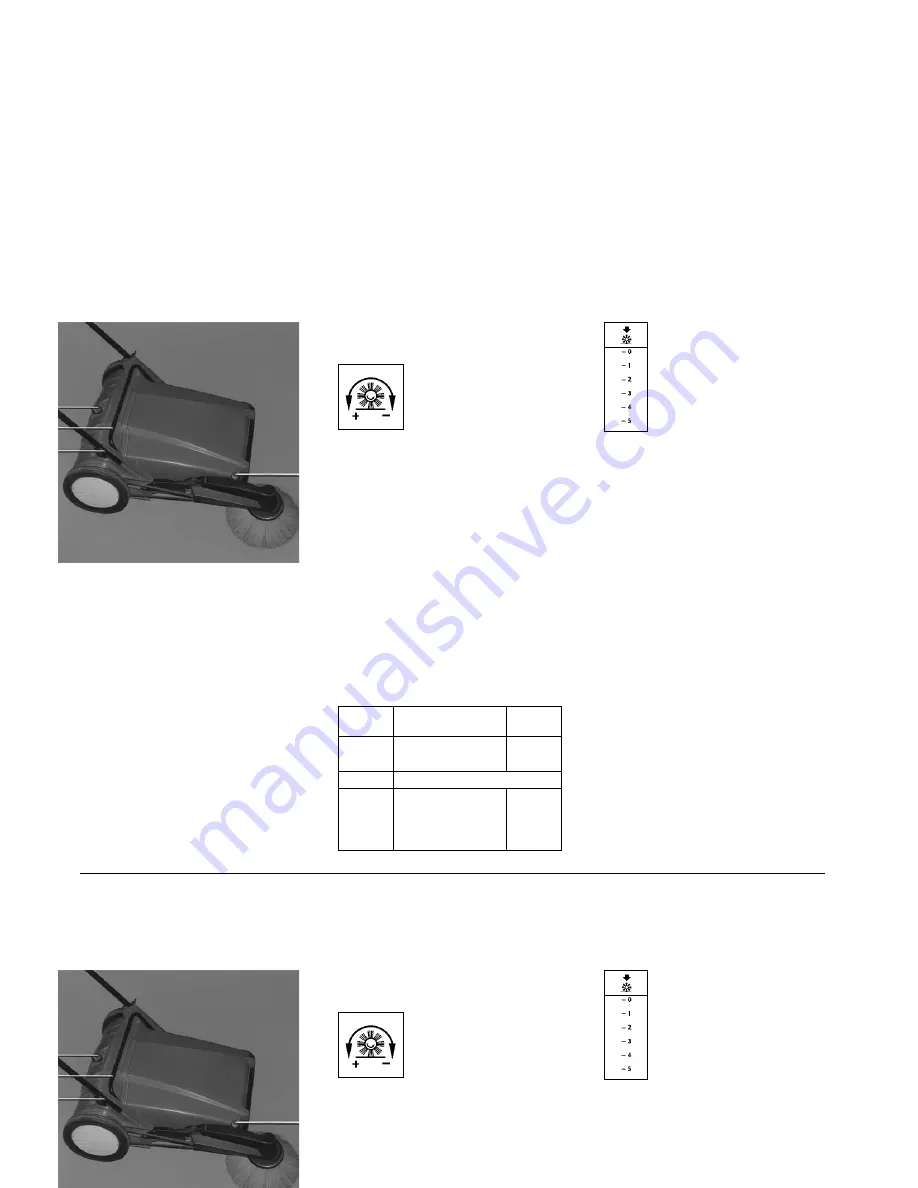

1 Handwheel for sweeping roller

adjustment

is used for adjustment of the swee-

ping roller ground pressure.

The sweeping roller ground pres-

sure should be adjusted as recom-

mended by us, or be adapted to

local conditions, until good swee-

ping performance will be achieved.

Adjustment is indicated by the

scale close to the track wheel.

Recommended adjustment

(valid for sweeping roller in ”as

new“ condition“)Basic adjustment:

Scale code 1.5

1 handwheel for sweeping roller

adjustment

2 hopper handle

3 butterfly nuts for fixing of handlebar

4 handwheel with knurled nut for side

brush adjustment

Note:

Sweeping roller ground pres-

sure, if adjusted to too high a

value, requires higher physical

force to push the machine, and

increases the wear of brooms. Best

sweeping performance will be

achieved at

2.5 m.p.h. = 4 km.p.h., i. e. normal

pedestrian’s speed.

2 Hopper handle

is used to remove the dust hopper.

3 Butterfly nuts for fixing

of handlebar

are used to secure the handlebar.

I

Scale

litter

ground

code

1

light-weight,

unruffled

dry litter

1.5

basic adjustment

2

heavy dirt, or big

rough

dirt quantities;

or

humid or sticky

uneven

dirt

1

2

3

1

8

Controls

1 Handwheel for sweeping roller

adjustment

is used for adjustment of the swee-

ping roller ground pressure.

The sweeping roller ground pres-

sure should be adjusted as recom-

mended by us, or be adapted to

local conditions, until good swee-

ping performance will be achieved.

Adjustment is indicated by the

scale close to the track wheel.

Recommended adjustment

(valid for sweeping roller in ”as

new“ condition“)Basic adjustment:

Scale code 1.5

1 handwheel for sweeping roller

adjustment

2 hopper handle

3 butterfly nuts for fixing of handlebar

4 handwheel with knurled nut for side

brush adjustment

Note:

Sweeping roller ground pres-

sure, if adjusted to too high a

value, requires higher physical

force to push the machine, and

increases the wear of brooms. Best

sweeping performance will be

achieved at

2.5 m.p.h. = 4 km.p.h., i. e. normal

pedestrian’s speed.

2 Hopper handle

is used to remove the dust hopper.

3 Butterfly nuts for fixing

of handlebar

are used to secure the handlebar.

I

Scale

litter

ground

code

1

light-weight,

unruffled

dry litter

1.5

basic adjustment

2

heavy dirt, or big

rough

dirt quantities;

or

humid or sticky

uneven

dirt

1

2

3

1

Summary of Contents for Sweepmaster M600

Page 1: ...OTUSVDUJPO BOVBM Instruction Manual Sweepmaster M600...

Page 2: ......