HP SERIES

PORTABLE PUMPS

USER OPERATION AND MAINTENANCE

28

7

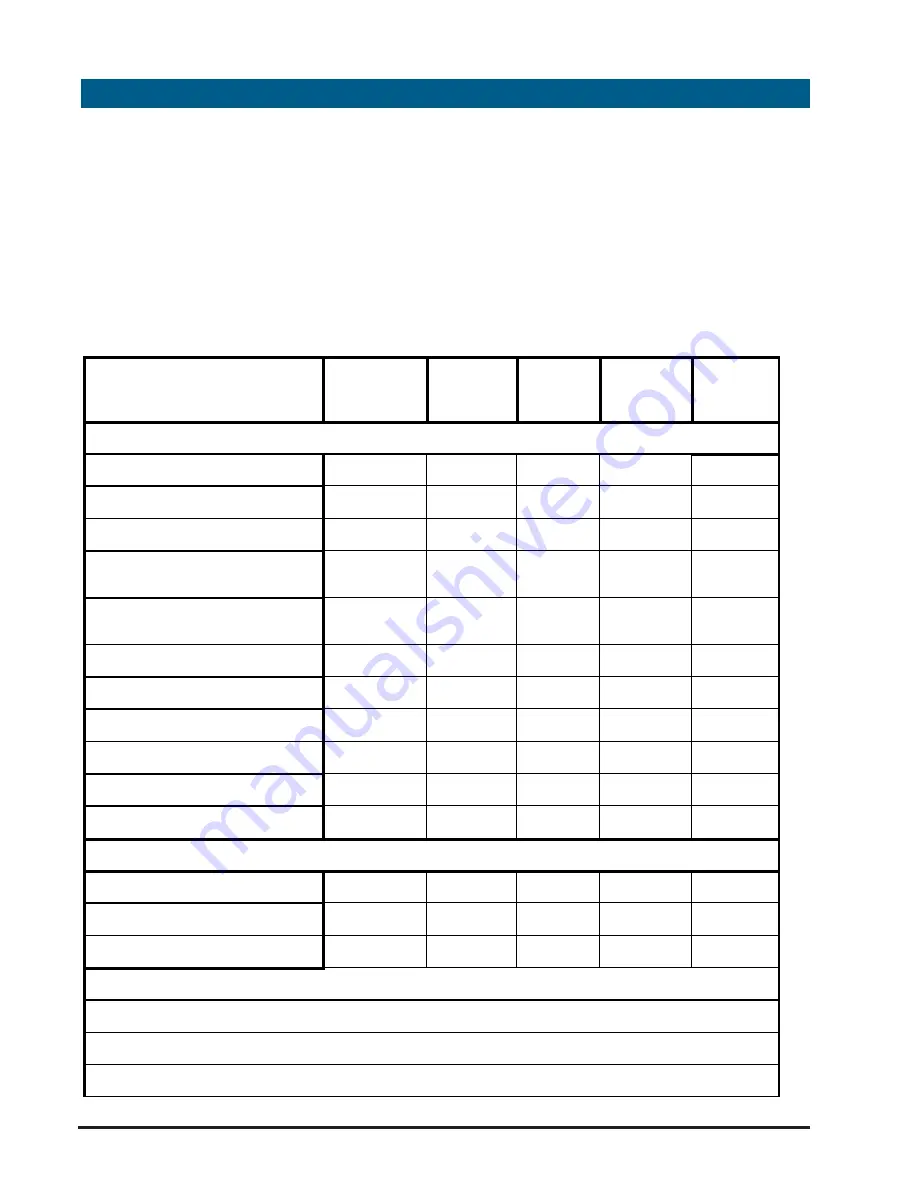

MAINTENANCE SCHEDULE

MAINTENANCE INTERVALS

To prolong pump life and ensure reliable operation the pump user shall perform the

maintenance described in the following section on a regular basis. The table that

follows provides a listing of the minimum maintenance intervals. Following the chart

are detailed maintenance procedures.

MAINTENANCE OPERATION

Every 8

Hours or

Daily

25 Hours or

Weekly

50 Hours

or Monthly

100 Hours

or Yearly

Yearly

ENGINE MAINTENANCE

Check Oil Level

●

Change Oil † (NOTE 1)

●

Change Oil Filter

●

Clean Foam Air Cleaner

Pre-Cleaner (NOTE 2)

●

Service Air Cleaner Cartridge

(NOTE 2)

●

Clean Cooling System (NOTE 2)

●

Clean Debris Gard (NOTE 2)

●

Inspect Spark Arrester

●

Replace In-Line Fuel Filter

●

Replace Spark Plug

●

Check Valve Clearance

●

PUMP MAINTENANCE

Check Oil Level (NOTE 3)

●

Change Gear Oil (NOTE 3)

●

Leak Test

●

† : Change oil after first 8 hours.

NOTE 1: Change oil every 25 hours when operating under heavy load or in high ambient temperature.

NOTE 2: Clean more often under dusty conditions or when airborne debris is present.

NOTE 3: HP100 Model Pump Only.

Summary of Contents for HP 400

Page 2: ...HP SERIES PORTABLE PUMPS USER OPERATION AND MAINTENANCE 2...

Page 4: ...HP SERIES PORTABLE PUMPS USER OPERATION AND MAINTENANCE 4...

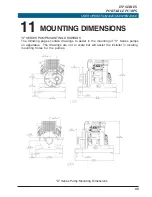

Page 44: ...HP SERIES PORTABLE PUMPS USER OPERATION AND MAINTENANCE 44 X Series Pump Mounting Dimensions...

Page 48: ...HP SERIES PORTABLE PUMPS USER OPERATION AND MAINTENANCE 48 I Series Pump Dimensions...

Page 72: ......