Page

49

SmartFOAM

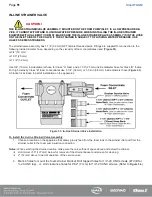

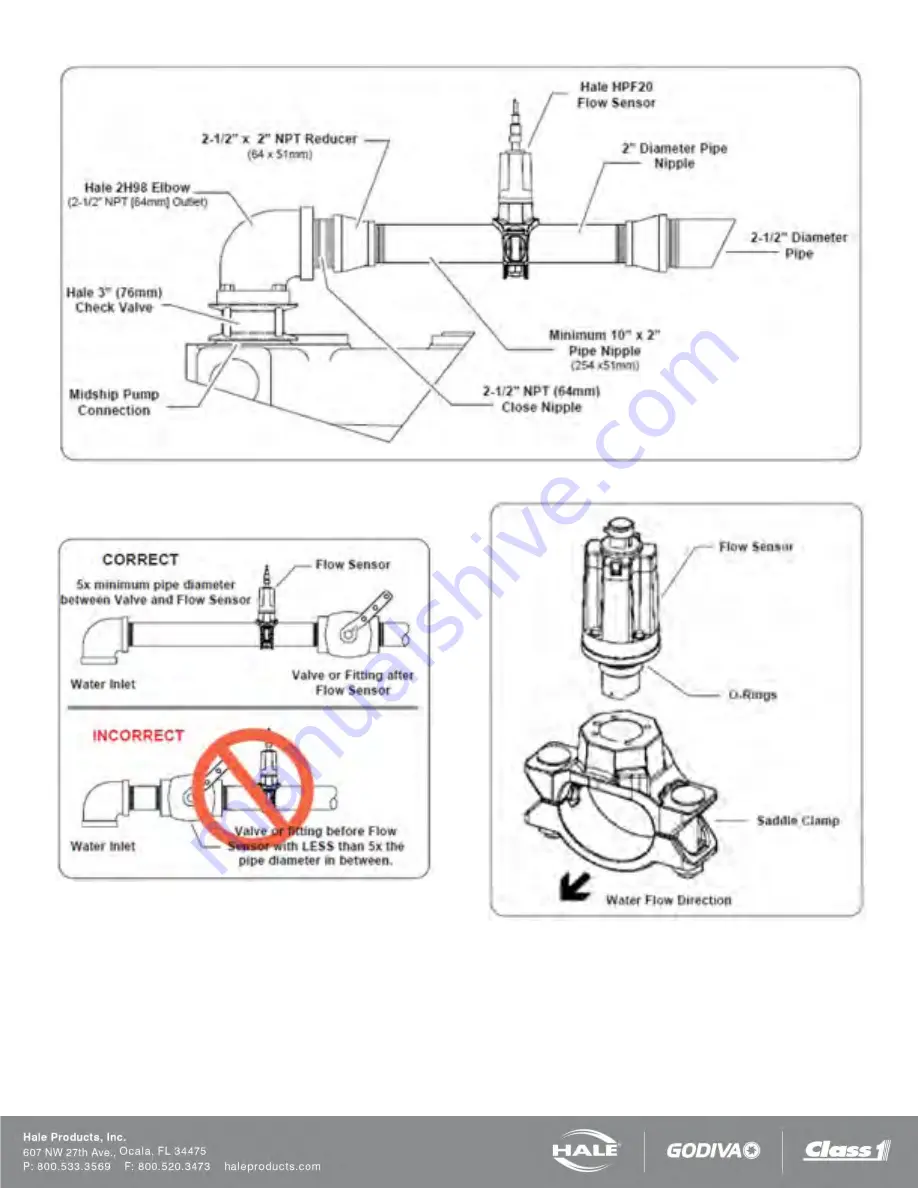

Figure 30: Typical Reduced Size Sensor Piping Arrangement

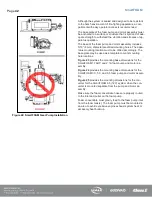

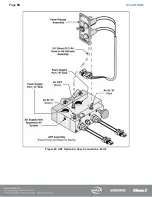

Figure 31: Flow Sensor Placement

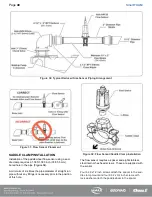

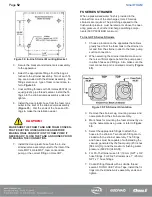

SADDLE CLAMP INSTALLATION

Installation of the paddlewheel flow sensor using a sad-

dle clamp requires a 1.385/1.390 inch (35/35.3 mm)

bored hole in the pipe (

).

A minimum of six times the pipe diameter of straight run

pipe without any fittings is necessary prior to the position

of this hole.

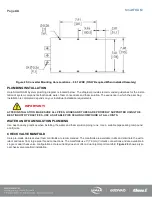

Figure 32: Flow Sensor/Saddle Clamp Installation

The flow sensor requires a spacer and eight stainless

steel internal hex head screws. These are supplied with

the sensor.

Four 6-32 x1/2 inch screws attach the spacer to the sad-

dle clamp mount and four 6-32 x 3/4 inch screws with

lock washers attach the paddlewheel to the spacer.

Summary of Contents for MiniCAFS 2.1A

Page 3: ...Page 2 SmartFOAM NOTES...

Page 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

Page 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Page 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Page 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Page 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Page 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Page 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Page 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

Page 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Page 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Page 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Page 77: ...Page 76 SmartFOAM NOTES...

Page 90: ...89 Page 89 SmartFOAM NOTES...