Page

50

SmartFOAM

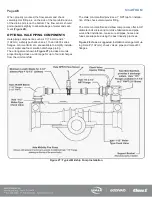

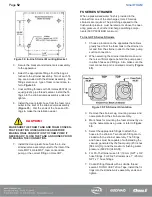

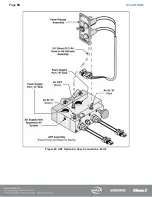

Align the indexing pin of the saddle clamp to the index-

ing hole of the spacer to align the saddle clamp mount.

Secure with four 1/2-in machine screws, no lock wash-

ers. Torque to 8.5 in.-lbs. (1.0 N-m).

Align the paddle wheel indexing pin to the indexing hole

in the spacer and secure using four 3/4” screws and lock

washers. Torque to 7.5 in.-lbs. (0.9 N-m).

Apply a small amount of grease to the saddle clamp gas-

ket before the final installation of the assembly onto the

pipe. Firmly tighten the saddle clamp onto the pipe.

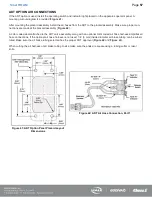

FOAM PUMP FLUSH SYSTEM

Dual Tank System

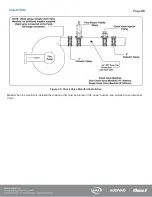

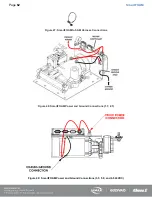

Flushing water must be provided to flush the system of

foam concentrate after each use. This prevents adverse

reactions of some foam concentrates should they mix to-

gether. The Hale ADT and MDT II each have provisions

for connecting flushing water to the foam concentrate in-

jection system. If 2 MDT II are required, each will need

its own flush line.

Single Tank System

The Hale MST provides a selector valve and gives the

system flush capabilities for NFPA compliance. A fitting

provided on the Hale MST simplifies the flushing water

connection.

No Tank Option

The system installer must provide a flushing water sup-

ply to comply with NFPA standards.

The flushing water hose must be a minimum of 1/2-in

(12 mm) inside diameter and capable of withstanding the

maximum fire pump discharge pressure, 500 PSI (34

BAR) minimum. The flush water supply should be pro-

vided from one of the pressure taps on the discharge of

the fire pump.

It is recommended that a check valve be installed at the

pressure tap to prevent contamination. Flush water

thread connections are:

❑

ADT - 1/2-in (13 mm) NPT

❑

MDT II and MST - 1/4” (6.4 mm) NPT

The system installer must provide proper fittings for

these connections.

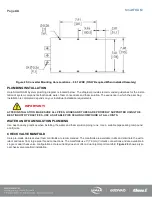

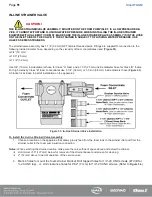

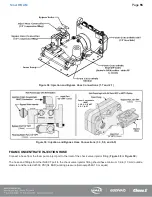

FOAM CONCENTRATE PLUMBING

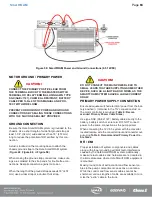

CAUTION!

MAKE SURE THE FOAM TANK AND FOAM CONCEN-

TRATE SUCTION HOSES ARE CLEAN BEFORE

MAKING A FINAL CONNECTION TO FOAM PUMP.

FLUSH TANK(S) AND HOSES PRIOR TO MAKING

CONNECTIONS. MAKE SURE THE FOAM CONCEN-

TRATE IS GRAVITY FED FROM THE TANK TO THE

PUMP.

Foam concentrate plumbing consists of:

❑

Foam concentrate suction hose

❑

Foam strainer

❑

Foam concentrate discharge hose

❑

Check valve/injector fitting

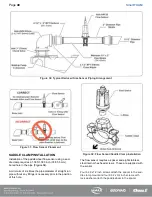

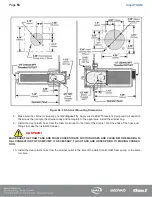

FOAM STRAINER CONNECTION

CAUTION!

THE FOAM CONCENTRATE STRAINER ASSEMBLY,

MOUNTED ON THE FOAM PUMP INLET, IS A LOW

PRESSURE DEVICE. IT WILL NOT WITHSTAND

FLUSHING WATER PRESSURE. IF FLUSHING WA-

TER IS TO BE PROVIDED THE PRESSURE MUST BE

LIMITED TO 50 PSI (3.5 BAR).

The strainer/valve assembly has 1/2-in (12 mm) NPT fe-

male threaded ports. A 1/2-in hose barb fitting is sup-

plied to connect the 1/2-in ID hose, provided with the

Hale SmartFOAM 2.1A installation kit.

The hose from the foam tank to the strainer must have

adequate wall stiffness to withstand the vacuum of the

foam pump while it is operating (23” [584 mm] Hg and

50 PSI [3 BAR], Kuriyama, Kuri-tec K-3130 or K-7130

series or equal).

After the foam pump is mounted on the apparatus, con-

nect the PVC hose provided to the strainer inlet.

Install the clear plastic hose from the foam tank outlet to

the inlet of the strainer/valve assembly. The inlet is on

the valve end. Wetting the ends of the hose and fittings

makes the installation on the hose fittings easier.

CAUTION!

MAKE SURE THE FOAM TANK AND FOAM CONCEN-

TRATE SUCTION HOSES ARE CLEAN BEFORE

MAKING FINAL CONNECTION TO FOAM PUMP. IF

NECESSARY FLUSH TANK AND HOSES PRIOR TO

MAKING CONNECTION.

Summary of Contents for MiniCAFS 2.1A

Page 3: ...Page 2 SmartFOAM NOTES...

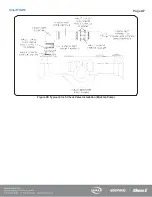

Page 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

Page 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Page 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Page 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Page 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Page 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Page 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Page 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

Page 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Page 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Page 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Page 77: ...Page 76 SmartFOAM NOTES...

Page 90: ...89 Page 89 SmartFOAM NOTES...