Page

38

SmartFOAM

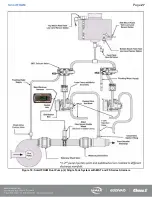

If panel mounted FS series strainers are installed, mount

the strainer in the foam concentrate hose that supplies

concentrate to the ADT, MDT II or MST. The FS series

strainer may also be mounted in the outlet hose of the

MDT II or MST.

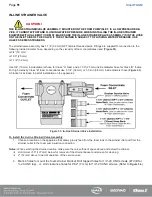

IMPORTANT!

WHEN DETERMINING THE STRAINER LOCATION

KEEP IN MIND THE REQUIREMENT FOR GRAVITY

FEED OF FOAM CONCENTRATE TO THE FOAM PUMP

THROUGH THE STRAINER AND AVOID AIR TRAPS IN

THE HOSES. ALSO, CLEARANCE MUST BE PRO-

VIDED TO ALLOW REMOVAL OF THE BOWL ASSEM-

BLY TO CLEAN THE STAINLESS STEEL MESH, TO

MAKE HOSE CONNECTIONS TO THE STRAINER AND

FOR OPERATION OF THE SERVICE VALVE.

The installer must provide a strainer service isolation valve

in the foam concentrate hose to prevent spillage during

service. An MST or MDT II can serve this purpose.

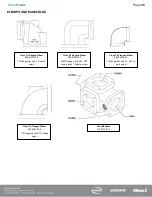

CONTROL UNIT AND INSTRUCTION /

SYSTEM DIAGRAM PLACARD

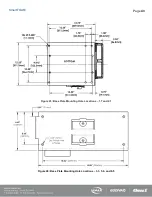

Determine a location on the operator panel of the appa-

ratus for the control unit and instruction/ system diagram

placard, if provided. These components must be located

at the main pump operator position in close proximity to

each other. Consideration must be given for routing the

control cable from the control unit to the motor controller

on the foam pump and motor assembly. If necessary, order

longer or shorter cable assemblies to suit the location de-

mands.

INSTALLER SUPPLIED COMPONENTS

Due to the many differences in apparatus configurations

and design requirements the Hale SmartFOAM system in-

staller must supply components such as:

❑

Mounting brackets

❑

Piping

❑

Hoses

❑

Fittings

❑

Electrical wiring

❑

Foam tank(s)

The following guidelines are recommendations for selec-

tion of additional components for a complete system instal-

lation. These recommendations reflect materials and com-

ponents that are tested extensively with Hale SmartFOAM

systems and provide proven reliable performance.

Always obviously/uniquely label the wiring for the 6.5 24V

portion of the foam system when installed on a 12V appa-

ratus.

FOAM CONCENTRATE SUCTION HOSE

SmartFOAM 2.1A and 1.7 AHP Foam systems

These systems are provided with 15 ft (4.6 m) of 1/2-in

(13 mm) ID reinforced PVC foam concentrate suction hose.

The system installer may need to supply additional fittings

and hose from the foam tank to the inlet of the foam pump.

All components selected transfer foam concentrate; there-

fore they must be compatible with the foam concentrates be-

ing used in the system.

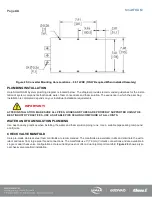

SmartFOAM 3.3, 5.0, and 6.5 Foam systems

Hoses for Class “A” foam concentrates have minimum 3/4-in

(19 mm) inside diameter. Hoses for Class “B” foam concen-

trates must have a minimum 1-in (25.4 mm) inside diameter

due to higher viscosity of the concentrate.

Note: Certain types of Class “B” AFFF-ARC or ATC concen-

trates require a 1-1/4

-in

or 1-1/2

-in

(32 or 38 mm) ID foam

concentrate supply line.

Hoses for the foam concentrate suction that are not subject

to high pressure, i.e. flushing water or foam concentrate dis-

charge, must have a rating of 23 inHg (584 mm) vacuum

and 50 PSI (3.5 BAR) pressure or greater.

Note: NFPA requires that foam concentrate suction hose be

clear to observe foam concentrate flow during foam pump

operation.

Recommended components

Hose:

PVC, Kuriyama Kuri-Tec K3130 or K7130 series.

Fittings:

Hose Barb Type; Brass, Stainless Steel or Nylon.

Foam concentrate suction hose subjected to flushing water

pressure must be rated for 23 inHg (584 mm) vacuum and

the maximum discharge pressure of the fire pump (500 PSI

[34 BAR] minimum). These hoses include the hose from the

outlet of the MDT II or MST to the foam pump inlet.

Recommended components

Hose:

Aeroquip 2580 series or Equivalent Reinforced

Hydraulic Hose.

Fittings:

Brass or Stainless Steel Hose End Crimp or Reus-

able Type (Aeroquip 412 series or Equivalent).

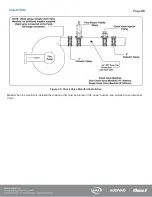

A foam tank shut-off valve and drain valve should be pro-

vided in the foam tank suction hose to allow strainer service,

tank drainage and easier priming.

These components are subject to the same material charac-

teristics and pressure ratings as stated above. When the In-

line strainer/valve assembly option is installed the shut-off

valve is included. A separate valve is not required.

Summary of Contents for MiniCAFS 2.1A

Page 3: ...Page 2 SmartFOAM NOTES...

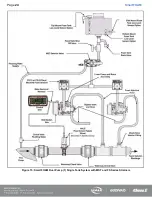

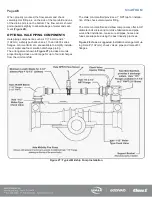

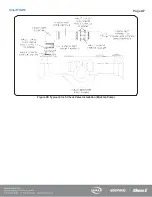

Page 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

Page 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Page 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Page 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

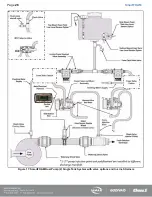

Page 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Page 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Page 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Page 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

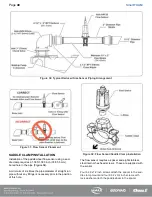

Page 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Page 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Page 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Page 77: ...Page 76 SmartFOAM NOTES...

Page 90: ...89 Page 89 SmartFOAM NOTES...