Page

40

SmartFOAM

system is ordered with the “no tank” option the

system installer must maintain NFPA compli-

ance. To be NFPA compliant, when flushing is

required, the system installer must provide

proper:

❑

Hoses

❑

Shut-off valves

❑

Check valves

❑

Reducer/regulator

❑

Connections for flushing water for the system

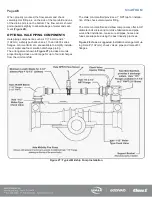

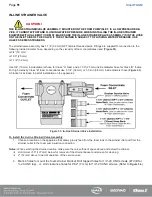

FOAM DISCHARGE DRAINS

Drains must be provided from foam capable discharge pip-

ing components to prevent freezing in cold weather. When

designing the drain system care must be taken to prevent

contamination of the water system with foam and the foam

concentrate with water. Some multiple drain systems that

allow individual drain lines to communicate also allow

foam to bypass the installed check valves causing contam-

ination of fire pump and the water or foam concentrate

storage tanks.

Hale offers an optional manual or air-operated 6-port drain

valve, Class1 Model MMD6 (p/n: 104961). The valve pro-

vides individual drains with a single control and is use for

applications where a single point for multiple drains is re-

quired. If a Hale MMD6 drain valve is not used, individual

drain lines and valves for foam capable discharge piping is

recommended.

APPARATUS DESIGN/BUILD FOR COLD

WEATHER (BELOW FREEZING) DUTY

If the end-user will use the fire apparatus in sub- freezing

temperatures, the onus is on the fire truck builder to build

into the apparatus design an appropriate ambient temper-

ature operating environment for the envelope where the

SmartFOAM system will be located. This routinely takes

on the form and function of mounting the SmartFOAM sys-

tem in a limited ventilation area that is served by an appro-

priate pump house auxiliary heater.

Simply, the fire truck builder must keep ambient air tem-

perature above 32°F (0°C) in the envelope around the

SmartFOAM hardware, including the base foam pump

unit, foam strainer, foam concentrate injection line, etc.

There are several best practices in the fire industry that

can be employed to meet this criteria and the fire truck

builder/designer can choose the best choice for their spe-

cific installation. Note that there must be ventilation availa-

ble to cool the area around the unit also, to prevent electric

motor overheating when the unit is operating in high tem-

perature ambient environments.

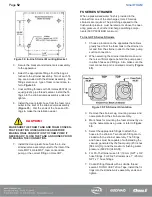

ELECTRICAL REQUIREMENTS

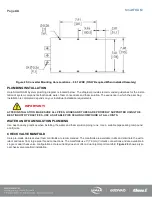

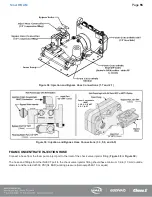

The system installer must provide the primary power wire

and a ground strap for the Hale SmartFOAM system.

Primary power must be supplied from the main apparatus

battery to the motor controller box on the foam pump and

motor assembly. The Hale SmartFOAM 2.1A and 1.7AHP

systems require a minimum of a 40 AMP electrical service.

The Hale SmartFOAM 3.3 and 5.0 systems require a mini-

mum of a 60 AMP electrical service. The Hale SmartFOAM

6.5 (12VDC) system requires a minimum of a 90 AMP elec-

trical service and the 6.5 (24VDC) system requires a mini-

mum of a 45 AMP electrical service.

For dual foam systems, the above minimum requirements

must be used to calculate the requirements for the units be-

ing installed. Primary electrical power must be supplied di-

rectly from the battery, the battery master disconnect switch,

or solenoids to the Hale SmartFOAM system. (Do NOT use

the chassis for the ground.)

IMPORTANT!

OTHER ELECTRICAL COMPONENTS MUST NOT BE

SUPPLIED FROM THIS WIRE. DO NOT CONNECT THE

PRIMER AND HALE SMARTFOAM USING THE SAME

POWER WIRE.

The primary power connection must be made so that power

is supplied to the Hale SmartFOAM when the main appa-

ratus electrical system is energized and the pump is in gear.

Use of a solenoid with a 150 AMP peak, 60 AMP continuous

rating (for the 6.5 12VDC system, use a solenoid with a 250

AMP peak, 90 AMP continuous rating)

is recommended.

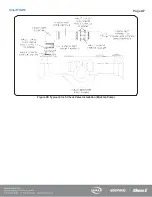

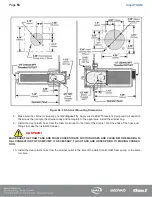

shows the recommended wiring for these relays.

Notes: This ensures immediate operation when the opera-

tor places the apparatus in PUMP mode, and to prevent bat-

tery power drain when the apparatus is not running.

Make certain that the recommended wire gage is selected

for the primary power connection based on the run length

(

Table 6: Recommended Primary Power Cable Sizes

).

Use solder lugs on cable ends with a 5/16-in (8 mm) diame-

ter hole.

Table 6: Recommended Primary Power Cable Sizes

Models 1.7 and 2.1

Maximum length

8 AWG (9mm

2

)

6 ft (1.8M) or less

4 AWG (21mm

2

)

6 ft (1.8M) to 15 ft (4.6M)

0 AWG (54mm

2

)

15 ft (4.8M) to 30 ft (9.1M)

Models 3.3, 5.0, & 6.5-24V

Maximum length

6 AWG (21mm

2

)

6 ft (1.8M) or less

2 AWG (34mm

2

)

6 ft (1.8M) to 15 ft (4.6M)

0 AWG (54mm

2

)

15 ft (4.8M) to 30 ft (9.1M)

Model 6.5-12V

Maximum length

4 AWG (21mm

2

)

6 ft (1.8M) or less

0 AWG (54mm

2

)

6 ft (1.8M) to 15 ft (4.6M)

00 AWG (68mm

2

)

15 ft (4.8M) to 30 ft (9.1M)

Summary of Contents for MiniCAFS 2.1A

Page 3: ...Page 2 SmartFOAM NOTES...

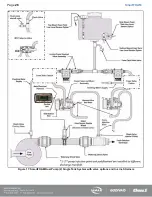

Page 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

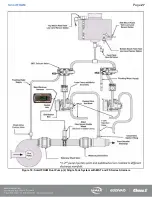

Page 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Page 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Page 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Page 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Page 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Page 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Page 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

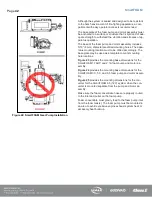

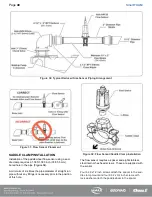

Page 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Page 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Page 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Page 77: ...Page 76 SmartFOAM NOTES...

Page 90: ...89 Page 89 SmartFOAM NOTES...