Page

65

SmartFOAM

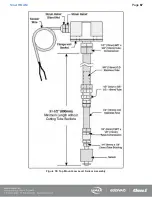

Side Mount Installation

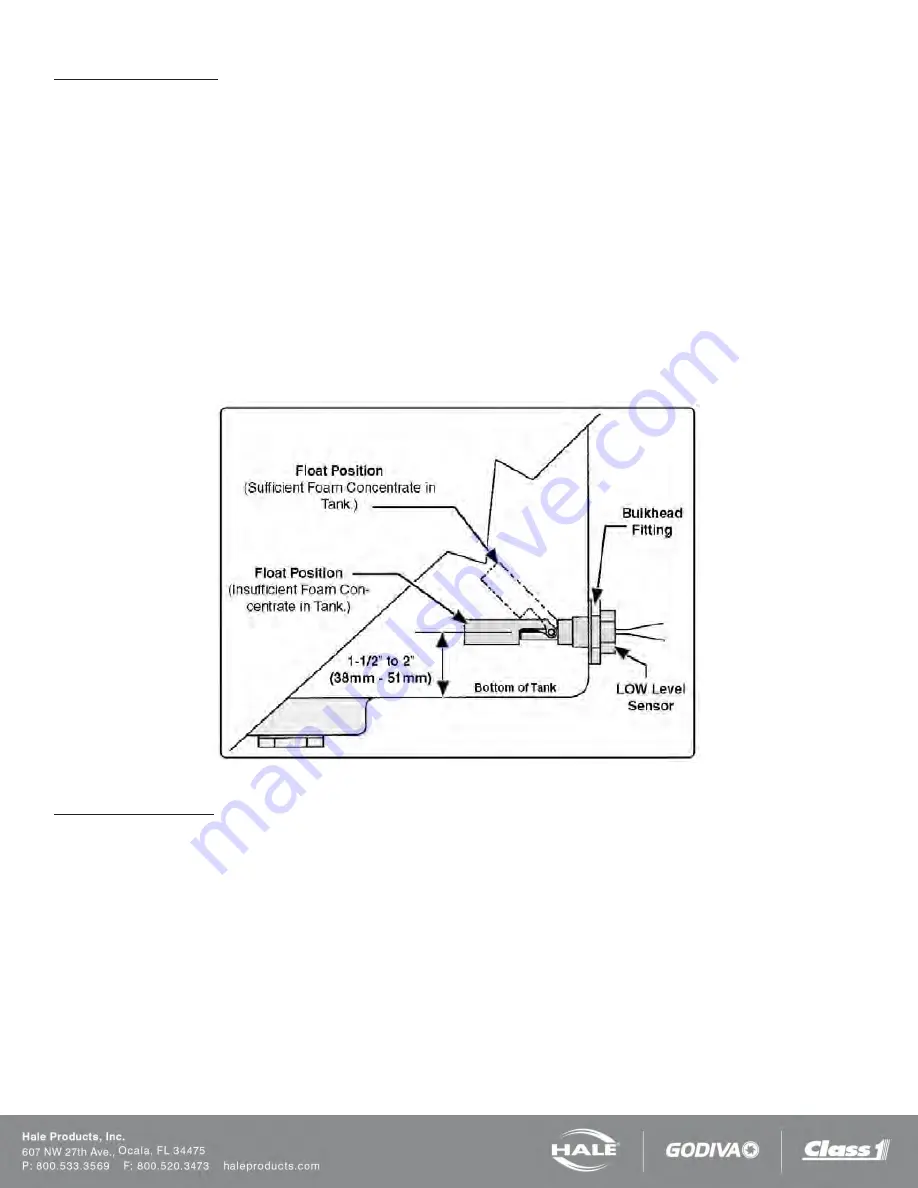

A side mount low tank level sensor is used if the bottom of the foam tank is not accessible.

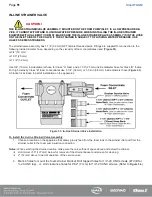

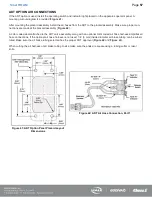

1. The sensor has 1/2-in (13 mm) NPT threads. If tank design and construction allows, the side mount sensor is

threaded directly into the side of the tank at the proper height (

). Also, the sensor can be mounted on

the foam tank using a 1/2-in x 1” (13 x 25 mm) NPT bushing and a bulkhead fitting with 1” (25 mm) FNPT threads.

2. The center of the switch must be located at least 1-½ to 2 inches (38 to 51 mm) from the bottom of the foam tank

with the float positioned on top of the switch to allow up and down movement.

Note: When the side mount low level sensor senses a low concentrate condition the system operates for an addi-

tional one minute unless the foam concentrate level is restored. If the foam concentrate level is not restored the

system SHUTS DOWN. When locating the side mount low tank level sensor on the tank sufficient foam concen-

trate should be present for one minute of operation at the rated flow.

3. Coat the threads of the sensor with a suitable sealant and insert into tank fitting. Tighten sensor making sure the

float is on the top of the sensor (

4.

After installation, check operation of the side mount low tank level sensor with a powered test light. With no foam

in the tank, the light should be ON. If light does not illuminate, rotate the side mount low tank level sensor until the

test light is ON.

Figure 53: Side Mount Sensor Location Dimensions

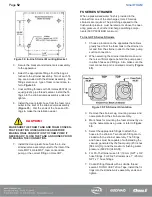

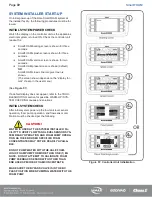

Top Mount Installation

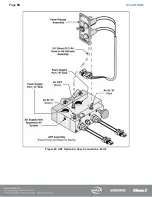

The top mount low level sensor assembly is available for installations where the sides or bottom of the foam tank are not

accessible, or sensor service is required without draining the foam tank.

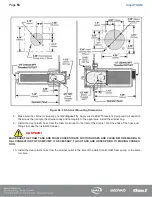

The sensor assembly is flange mounted in an access hole at the top of the foam tank. The two section telescoping as-

sembly permits adjustment of the low tank level sensor position for various foam tank depths from 31- 1/2-in to 60” (800

mm to 1,524 mm).

Flange cut-out dimensions are shown in

. The flange gasket can also be used as a template to mark hole loca-

tion.

Summary of Contents for MiniCAFS 2.1A

Page 3: ...Page 2 SmartFOAM NOTES...

Page 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

Page 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Page 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Page 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Page 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Page 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Page 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Page 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

Page 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Page 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

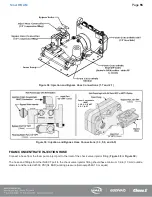

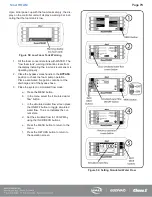

Page 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Page 77: ...Page 76 SmartFOAM NOTES...

Page 90: ...89 Page 89 SmartFOAM NOTES...