85

Page

85

SmartFOAM

DUAL TANK SYSTEM SELECTION

The following procedures are provided for operation with the

Hale ADT or MDT II Selectors.

CAUTION!

UNLESS ENGAGED IN CLASS “B” FOAM OPERATIONS,

THE HALE SMARTFOAM ADT TOGGLE SWITCH OR

HALE SMARTFOAM MDT II SELECTOR HANDLE MUST

BE IN THE TANK “A” POSITION. IF THE TOGGLE

SWITCH OR SELECTOR HANDLE IS IN THE FLUSH PO-

SITION WHEN THE FOAM PUMP IS STARTED, THE

FOAM PUMP RUNS FOR ONLY TWENTY (20) SECONDS,

THEN SHUTS DOWN.

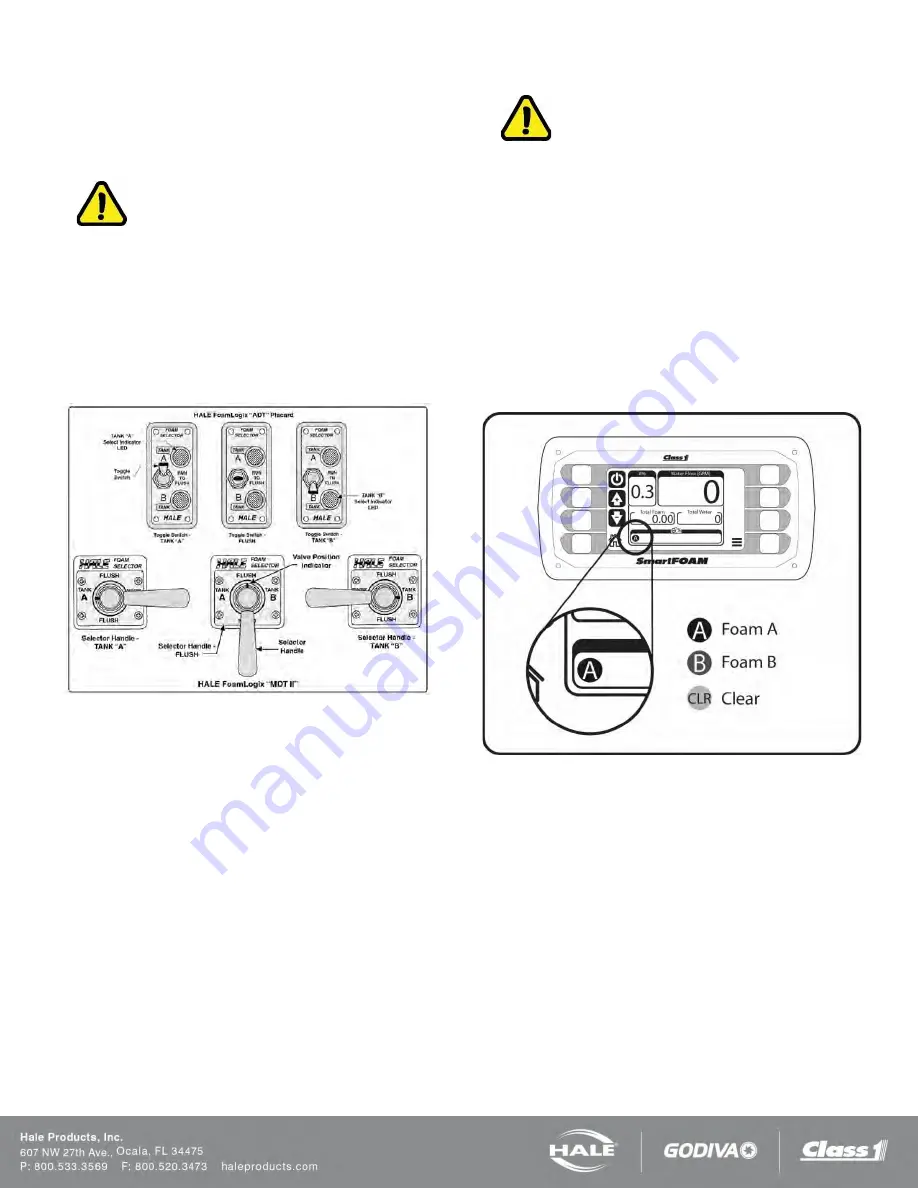

Figure 69: Dual Tank Selector Operating Positions

Make sure the Hale SmartFOAM is operating and foam solu-

tion is being discharged (

1. Set the Hale ADT toggle to the desired TANK, or

turn the Hale SmartFOAM MDT II handle until the in-

dicator points toward the desired TANK.

2. When changing toggle switch or selector handle po-

sition, move smoothly from the TANK

“

A” position

through the FLUSH position to TANK “B” position in

one motion without stopping. With the fire pump dis-

charging water and the Hale SmartFOAM operating,

a small volume of water is provided to separate the

two foam types helping to prevent possible adverse

reactions.

3. After completion of Class “B” foam operations,

briefly FLUSH the foam pump and return the Hale

SmartFOAM to the ready condition by returning to

the TANK “A” position and flowing a small amount of

Class “A” foam concentrate.

IMPORTANT!

MAKE SURE THE HALE SMARTFOAM DUAL TANK SYS-

TEM IS IN THE TANK “A” POSITION WHEN APPARATUS

IS PLACED IN THE READY CONDITION.

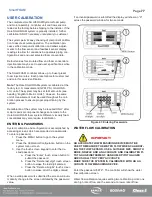

The SmartFOAM controller keeps track of which foam has

been selected via the selector handle and if that foam has

been run through the pump (

). The small round

icon in the bar graph indicates what foam is currently in the

pump: A, B, or CLR.

The SmartFOAM will display a warning message indicating

that a FLUSH operation must be performed if the operator

switches from one tank to the other without first FLUSHING.

The SmartFOAM controller will not allow operation of the

new tank until a FLUSH operation is performed.

Figure 70: SmartFOAM Foam in Pump Indicator

Summary of Contents for MiniCAFS 2.1A

Page 3: ...Page 2 SmartFOAM NOTES...

Page 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

Page 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Page 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Page 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Page 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Page 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Page 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Page 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

Page 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Page 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Page 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Page 77: ...Page 76 SmartFOAM NOTES...

Page 90: ...89 Page 89 SmartFOAM NOTES...