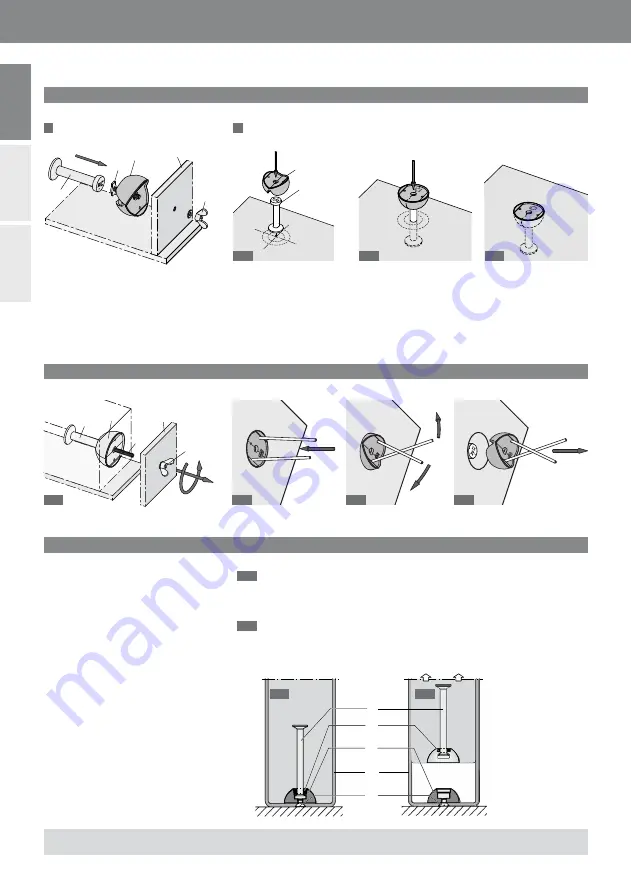

Part A: Installation procedure for all types

Installation using Rubber recess former

4. Installation with Steel recess former

1

To the formwork

2

From above into the fresh concrete

3. Removing the rubber recess former after the concrete is hardened

If installation is from above after casting the fresh concrete, the recess former

together with the pre-assembled HALFEN DEHA Spherical head anchor is

inserted at the specifi ed position by pushing and lightly rocking the recess

former until its top edge is fl ush with the concrete surface. Using formwork

lubricant, particularly in the inner of the recess former, is benefi cial when

stripping the formwork, and to improve the lifespan of the recess former.

In those cases where the precast unit

has to be lifted out of the mould

without having access to the recess

former, steel recess formers are used.

Two fi xing versions are available:

- for fastening with fi xing bolts

(steel or timber mould) and

- for magnetic fastening to steel

moulds, where holes cannot

be

drilled.

If this type of former is used to positi-

on the anchor horizontally within the

formwork, provisions should be taken

to prevent the anchor from becoming

dislodged when pouring the concrete

(e.g. by fi xing it to the reinforcement

or securing it with spacers).

After removing the mould the rubber

grommet

is separated from the

cast-in HALFEN DEHA lifting anchor.

4.1

Recess former plus spherical

head transport anchor after

installation, ready for

concreting.

4.2

Lifting the precast element

from the mould.

See also instructions

KKT-A

for the recess formers!

Fixing components

Formwork

Recess former

Spherical head lifting anchor

Fresh concrete

2.1

3.1

3.2

3.3

3.3

2.2

2.3

Rubber grommet

4.1

4.2

Auxiliary tool, i.e. reinforcement bar

2

© 2020 HALFEN · INST_KKT-E 07/15 · www.halfen.com

HALFEN KKT-E

Assembly Instructions

Deutsch

English

Polski