5. Once the axle stands are properly located, VERY SLOWLY turn the pole section of the handle

anti-clockwise until the vehicle begins to lower onto the stands. Lower the vehicle slowly so as

not to shock load the jack stands.

6. BEFORE GOING UNDER THE VEHICLE ensure that all axle stands and chocks are correctly

in place and there is no chance of the vehicle becoming unstable.

TO LOWER THE VEHICLE:

Once repairs are completed raise the vehicle slightly, remove the axle stands and VERY SLOWLY

turn the pole section of the handle anti-clockwise until the vehicle begins to lower.

CAUTION:

Ensure all body parts are kept clear of the jack and vehicle during the raising and

lowering operation.

MAINTENANCE, CARE AND LUBRICATION

1. This jack contains no user serviceable parts. Any modification will render the jack unsafe.

2. All moving joints require lubricating often. Lubricate all linkages, pivot points and castor wheels

using a grease gun.

3. Regularly check the plunger, main piston and linkages for signs of corrosion. Clean any light

surface corrosion with a suitable maintenance spray. If the corrosion is deeper than surface

do not attempt to use.

4. When not in use keep the jack stored on all 4 wheels with the arm and plunger all the way

down to prevent corrosion.

TO ADD OIL

IMPORTANT

When adding or replacing oil, ONLY use a quality hydraulic oil adhering to ISO VG 32

or similar. DO NOT use brake fluid, transmission fluid, alcohol, glycerine, detergent motor oil,

or dirty oil etc. as improper fluid will cause serious internal damage to jack making it unsafe to use.

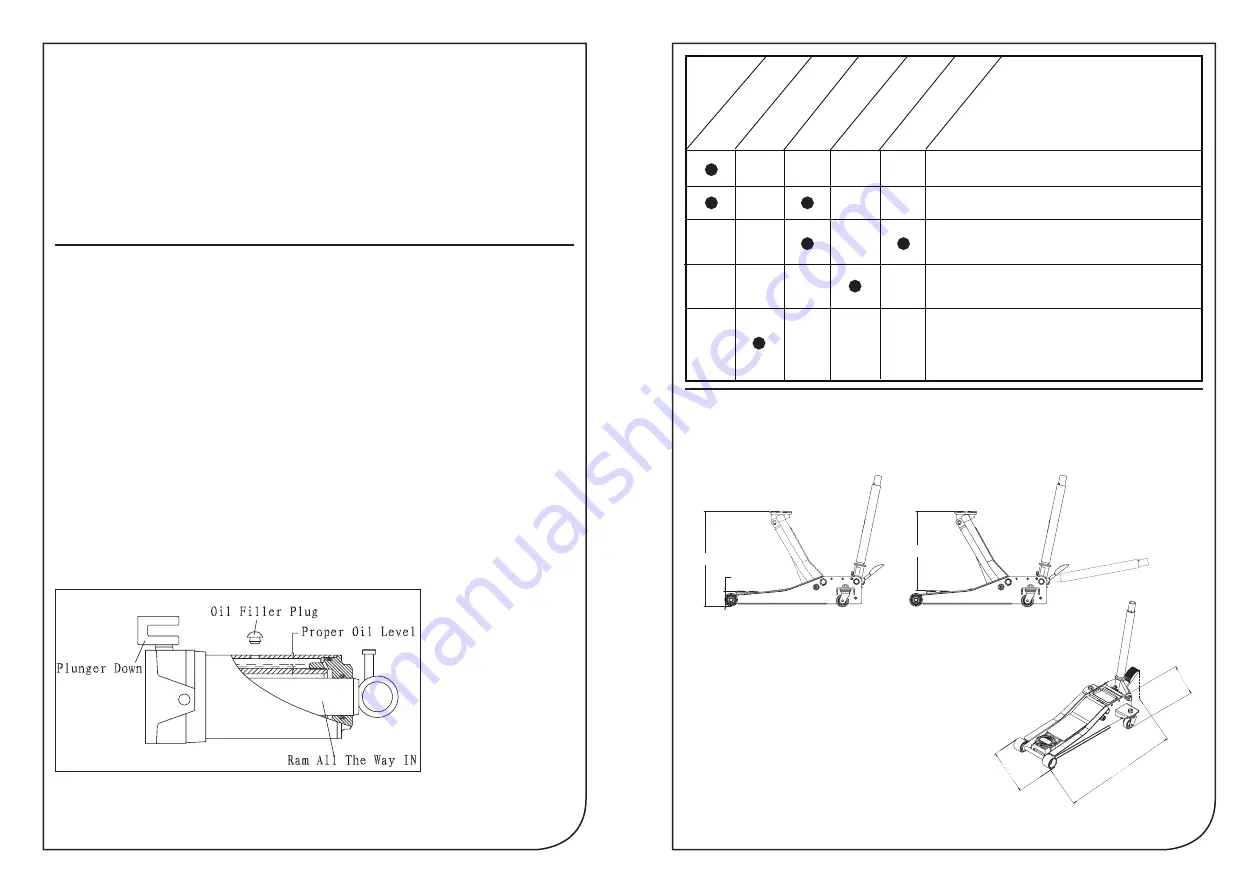

1. Place the jack on level ground with the lifting arm and plunger fully lowered.

2. Remove the top cover plate and clean the surrounding area of the oil filler plug and remove

ensuring that no dirt etc falls into the unit (see Fig.1).

3. Oil should be filled to level indicated in the diagram. If low, add hydraulic oil as required.

Maintenance and inspection:

The owner and/ or user must maintain and inspect the jack in

accordance with the manufacturer’s instructions.

SPECIFICATIONS

max.505mm

min.75mm

430mm

36

0m

m

16

0m

m

800

mm

Ja

ck w

ill

not

ho

ld l

oa

d

or

handle

ris

es

Ja

ck

will n

ot

lift

loa

d

PRO

BLE

MS

Ja

ck

will n

ot

lift

to

its

full

he

ight

Ja

ck

will

no

t lowe

r

co

mp

let

ely

Jack

wil

l n

ot

lift

sm

oot

hly

or

ja

ck

feels s

po

ng

y

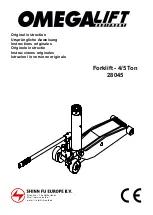

Trouble Shooting Check List

The release valve is not closed.

Turn the valve clockwise tightly.

Low on oil.

Refill the jack to the correct level of oil.

The hydraulic system is filled with air.Open the

release valve,pump handle rapidly (4) full strokes to

purge air, close release valve.

Return spring is broken or linkages binding.

Repace spring if broken.Grease pivot shaft,oil all

lift arm linkages.

Discharge ball is not sealing hydraulic system and oil

may be dirty.Manually flush hydraulic system by

raising and lowering lift arm by hand.Open the release

valve,as required to raise and lower the lift

arm.Manually raise and lower lift arm.

Fig.1

max.505mm

min.75mm

430mm

36

0m

m

16

0m

m

800

mm

Low height...........................................................7.5cm

High height........................................................ 50.5cm

Saddle diameter................................................... 11cm

Handle length...................................................112.5cm

Base length.......................................................... 80cm

Chassis width....................................................... 36cm

All dimensions are approximate.