With all clearance reduction systems using ventilated air space there shall be at least 1” clearance

between the reduction systems using ventilated air space.

Mineral wool batts, blanket or board shall have a minimum density of 8lb/ft

3

and a minimum melting

temperature of 1500

0

F.

Insulation material used as part of a clearance reduction system shall have a thermal conductivity of

1.0(Btu/In)/ (Ft

2

/Hr/

0

F).

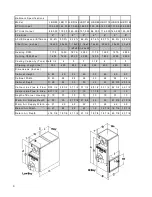

Table 2 Allowable Clearances with Specified Protection

Where the Specified Clearance with No Protection from the Appliance or

Chimney Connector

18” 12” 9” 6”

Type of protection applied to and

covering all surfaces within the distance

specified as the required clearance with

no protection

Above Rear

&

Sides

Above Rear

&

Sides

Above Rear

&

Sides

Above Rear

&

Sides

3½” thick masonry wall without

ventilated air space

N/A

12”

N/A

9”

N/A

6”

N/A

5”

½” insulation board over 1” glass fiber

or mineral wool batts

12” 9” 9” 6” 6” 5” 4” 3”

24 gauge sheet metal over 1” glass fiber

or mineral wool batts reinforced with

wire on rear face with ventilated air

space

9”

6”

6”

4”

5’

3”

3”

3”

3½” thick masonry wall with ventilated

air space

N/A 6” N/A 6” N/A 6” N/A 6”

24 gauge sheet metal with ventilated air

space

9”

6”

6”

4”

5”

3”

3”

2”

½” insulation board with ventilated air

space

9” 6” 6” 4” 5” 3” 3” 3”

24 gauge sheet metal with ventilated air

space over 24 gauge sheet metal with

ventilated air space

9”

6”

6”

4”

5”

3”

3”

3”

1” glass fiber or mineral wool batts

sandwiched between 2 sheets 24 gauge

sheet metal with ventilated air space

6” 6” 6” 4” 5” 3” 3” 3”

If the furnace is to be installed in a residential garage, the furnace must be a minimum of 18” above

the garage floor and located so it cannot be damaged by a moving vehicle

6

Summary of Contents for HBD1 15

Page 17: ...17 17...

Page 31: ...31...