Operating Instructions: Single Action Escape Release Head & Handle

6

Tools and Fixings Required

Ø8.2mm Drill

Ø6.2mm Drill

3 x M8 screws

(Rear fixing)

3 x M8 Washers

3 x M6 Screws

3 x M6 Nuts

(Optional)

3 x M6 Washers

Mounting (Escape Release

Head)

1.

Locate the amGard

pro

unit containing the escape release head so it is in a suitable position for the accompanying

amGard

pro

stack and within reach for easy user operation.

2.

Remove the tongue assembly from the unit by removing the locking means (e.g. Solenoid, Key, etc.) and pulling the

tongue out of the head by means of the silver handle.

3.

Mount the enclosure assembly together with head assembly to a flat metal, static part of the machine. Use M8 screws from

the rear. The mounting surface should be flat.

4.

The head may be rotated in increments of 180° to suit the installation.

i.

Remove M5 pin hex screws from host (

pro

LOK /

pro

LOK+) lid.

ii.

Remove 2 x M4 screws retaining head and remove the M4 screws and clamp.

iii.

Turn to preferred orientation.

iv.

Replace clamp, 2 x M4 head fixing screws, lid and lid screws.

5.

Make sure that the gap around the perimeter of the guard, when closed (Safety Circuits Closed), does not exceed the limits

specified in the relevant standards.

6.

All fixing screws must be permanently prevented from removal,either by vibration or by personnel using standard tools.

7. Ensure each of the three M8 head fixings are used to guarantee correct operation and maximum head

retention force.

8.

The installation and operation of the complete guard interlocking device must take into account the requirements of EN

ISO 14119; in particular Section 7 – Design for minimising defeat possibilities.

9.

The complete guard interlocking device must not be used as a mechanical stop. Where applicable, precautions must be

made to ensure the door or gate of any guarded area has sufficient support and stops to prevent the impact on the guard

interlocking device.

10.

The complete guard interlocking device must be mounted in the correctly assembled condition so that the escape

release action is only possible from within the guarded area (danger zone).

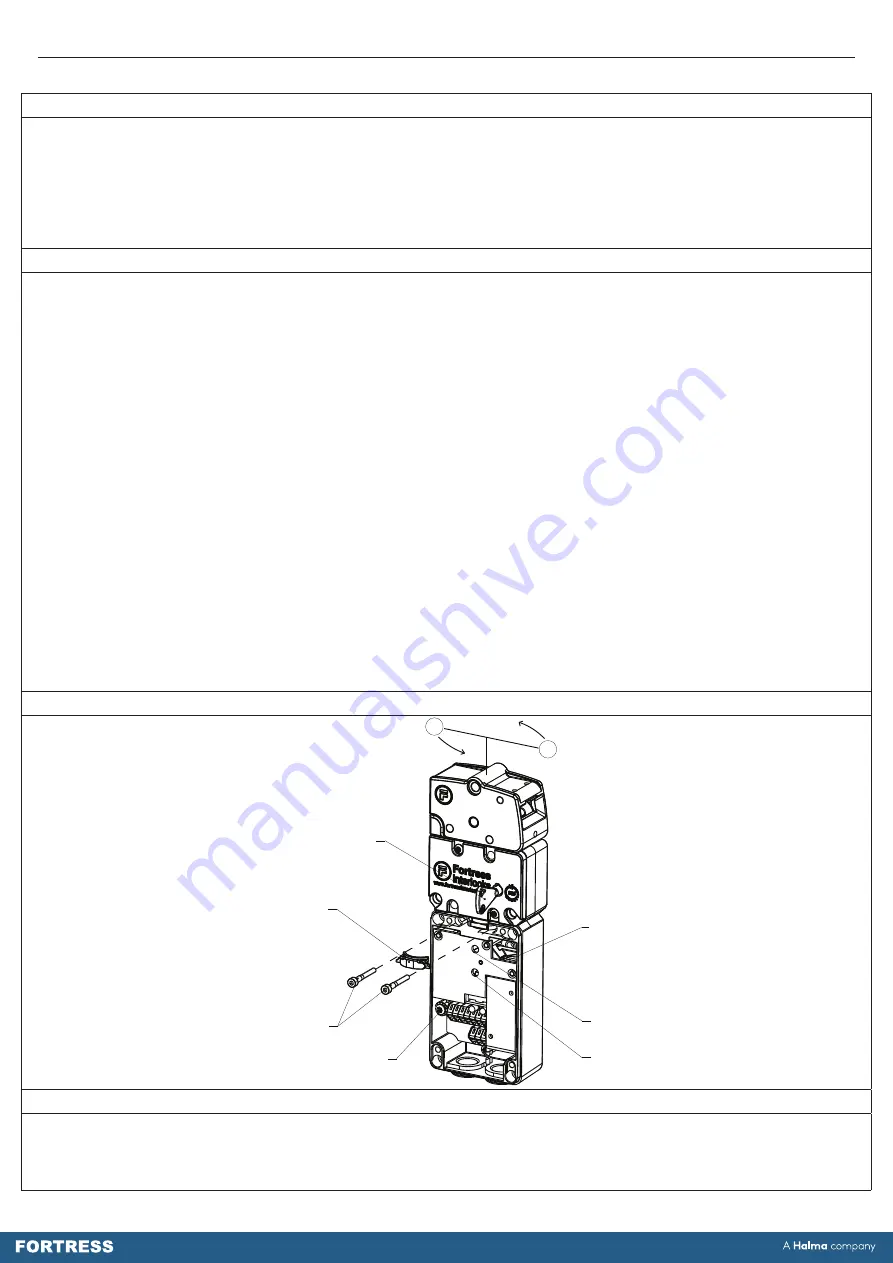

Figure 6:

Mounting (Escape Release Handle)

1.

Mount the unit only in its correctly assembled condition: i.e. Ensure unit is assembled for the correct handing required for

the particular installation.

2.

Locate the handle so that it is within easy reach. Locate the interlock so that operation of the auxiliary unlocking

mechanism, and inspection and replacement of the interlock are possible.

www.fortressinterlocks.com

Fortress

Interlocks

NEW STLYE I6 HEAD CAN BE ROTATED WHILST STILL ATTACHED TO LOK

2

4

Escape Release

Reset Key for I6 & I7

Versions Only

M4 x 30 Cap

Head Screws

Solenoid

Plunger

Upper

Plunger Hole

Earth Point

Lower

Plunger Hole

Clamp