Page 18

Diagnostics

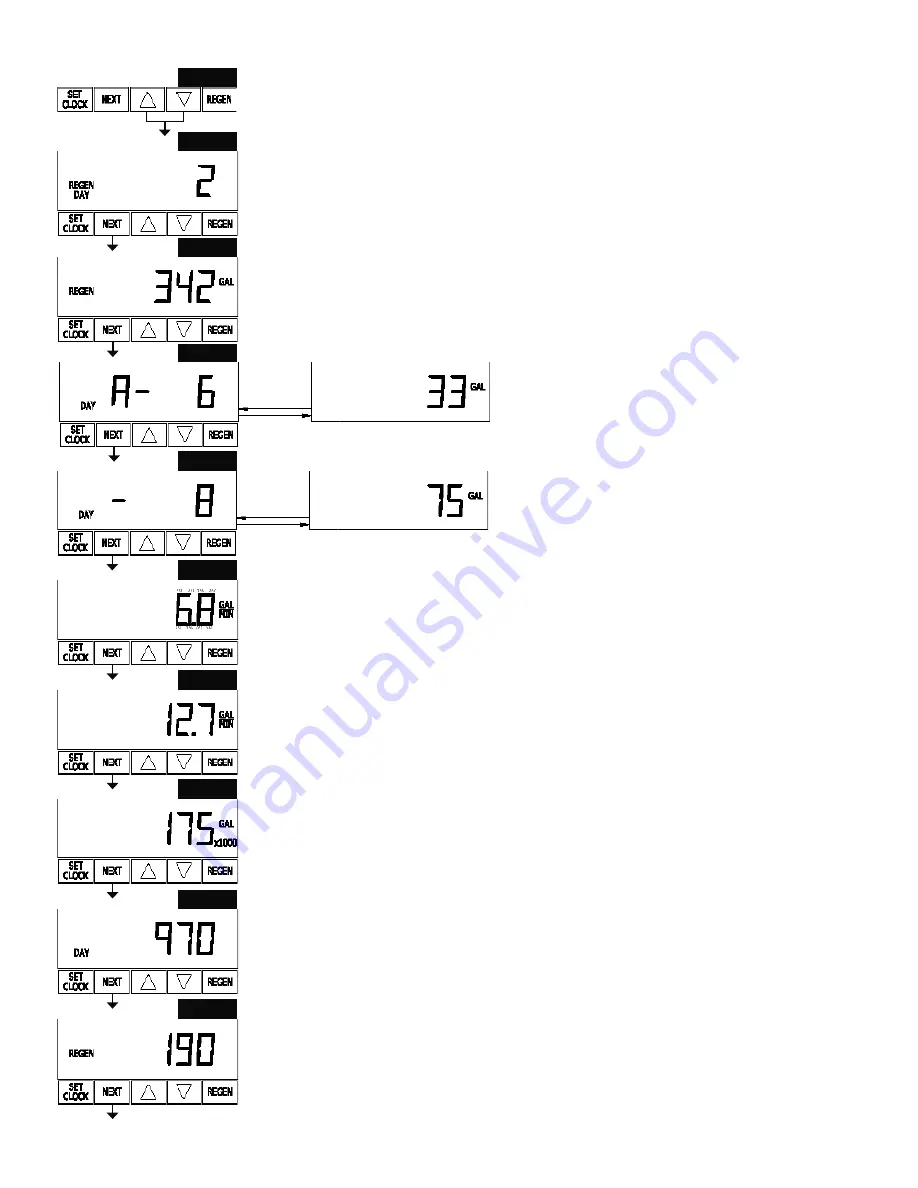

STEP 1D

– Press Down or Up simultaneously for three seconds. If screen in step 2D does not appear in

5 seconds the lock on the valve is activated. To unlock press

Down, NEXT, Up, and SET CLOCK in sequence, then press NEXT and Down simultaneously for 3

seconds.

STEP 2D

– Days, since last regeneration: This display shows the days since the last re gen er a tion

occurred. Press the NEXT button to go to Step 3D. Press REGEN to exit Diagnostics.

STEP 3D

– Gallons, since last regeneration: This display shows the number of gallons that have been

treated since the last re gen er a tion. This display will equal zero if a water meter is not installed. Press the

NEXT button to go to Step 4D. Press REGEN to return to previous step.

STEP 4D

– Gallons, reserve capacity used for last 7 days: If the valve is set up as a softener, a meter

is installed and Set Gallons Capacity is set to “Auto,” this display shows 0 day (for today) and fl ashes

the reserve capacity. Press ing the s button will show day 1 (which would be yesterday) and fl ashes the

reserve capacity used. Press ing the s button again will show day 2 (the day before yesterday) and the

reserve capacity. Keep pressing the s button to show the gallons for days 3, 4, 5 and 6. The Down button

can be pressed to move back wards in the day series. Press the NEXT button at any time to go to Step

5D. Press REGEN to return to previous step.

STEP 5D

- Gallons, 63 day usage history: This display shows

day 1 (for yesterday) and fl ashes the number of gallons treated

yesterday. Pressing the Up button will show day 2 (which would

be the day before yesterday) and fl ashes the number of gallons

treated on that day. Con tin ue to press the s button to show the

max i mum number of gallons treated for the last 63 days. This

display will show dashes if a water meter is not installed. Press

the NEXT button at any time to go to Step 6D. Press REGEN to

return to previous step.

STEP 6D

– Flow rate, current: Turn the water on at one or

more taps in the building. The fl ow rate in gallons per minute

will be displayed. If fl ow stops the value will fall to zero in a few

seconds. This display will equal zero if a water meter is not installed. Press the NEXT button to go to Step

7D. Press REGEN to return to previous step.

STEP 7D

– Flow rate, maximum last seven days: The maximum fl ow rate in gallons per minute that

occurred in the last seven days will be displayed. This display will equal zero if a water meter is not

installed. Press the NEXT button to go to Step 8D. Press REGEN to return to previous step.

STEP 8D

– Gallons, total used since last reset: The total number of gallons used since last reset will be

displayed. This display will equal zero if a water meter is not installed. Press the NEXT button to go to

Step 9D. Press REGEN to return to previous step.

STEP 9D

– Days, total number since last reset: The total number of days the control valve has been in

service since last reset will be displayed. Press the NEXT button to go to Step 10D. Press REGEN to

return to previous step.

STEP 10D

– Regenerations, total number since last reset: The total number of re gen er a tions that have

occurred since last reset will be displayed. Press the NEXT button to exit Di ag nos tics. Press REGEN to

return to previous step.

When desired, all information in Diagnostics may be reset to zero when the valve is

installed in a new location. To reset to zero, press NEXT and

t

buttons simultaneously to

go to the Service/OEM screen, and release. Press

Down

and

Up

simultaneously to reset

diagnostic values to zero. Screen will return to user display.

RETURN TO

NORMAL MODE

STEP 1D

STEP 2D

STEP 3D

STEP 4D

STEP 5D

STEP 6D

STEP 7D

STEP 8D

STEP 9D

STEP 10D