Supplied By www.heating spares.co Tel. 0161 620 6677

14

21

20

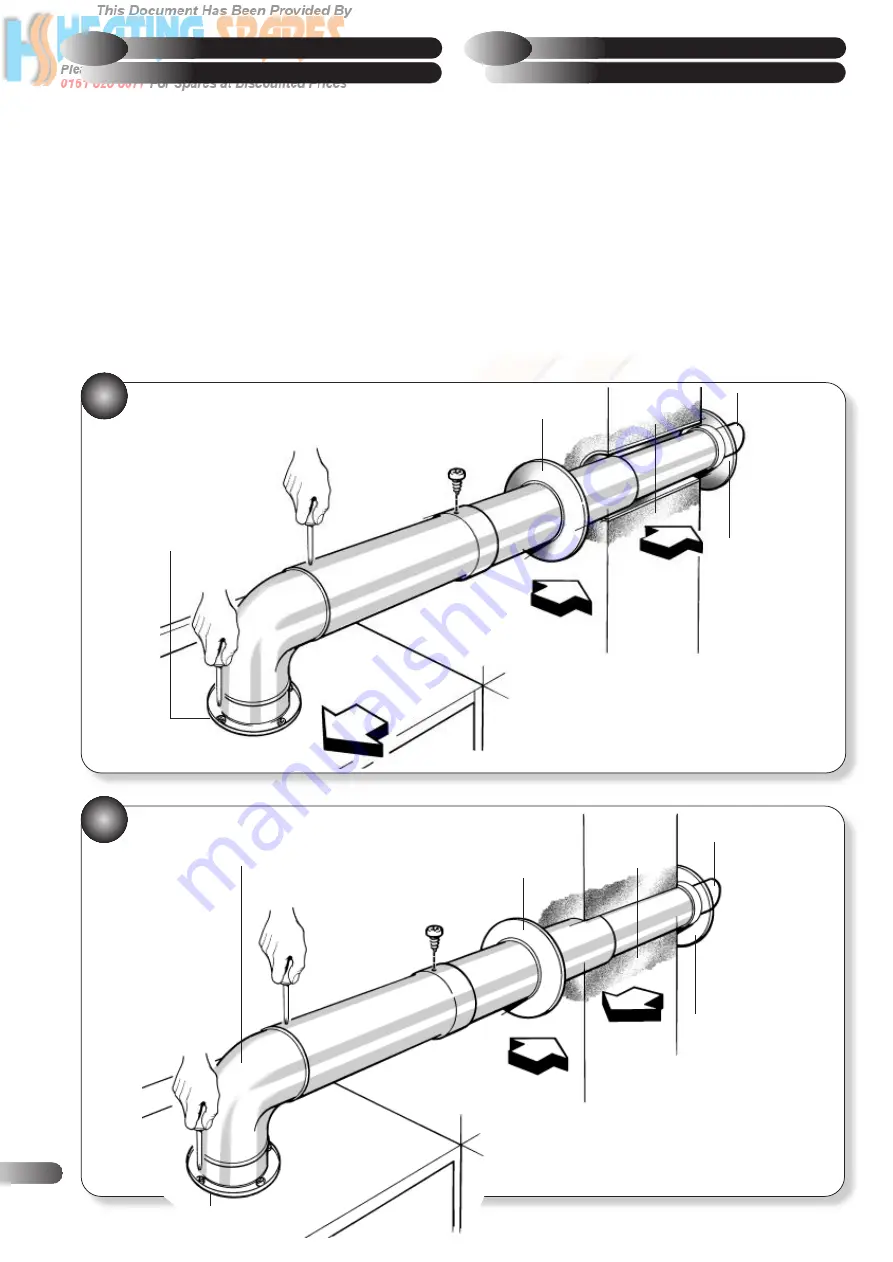

INSTALLING THE FLUE SYSTEM

FROM INSIDE THE ROOM

4.5.2

INSTALLING THE AIR/FLUE DUCT

FROM INSIDE THE ROOM

Wall thickness up to 800mm (31in) only.

a)

Push the terminal through the wall liner taking care to ensure

that the terminal is the correct way round and the external

wall sealing ring does not become dislodged.

b)

Pull the flue system towards the boiler to seat the external

sealing ring against the outside wall and secure the elbow to

the boiler using the screws provided.

c)

Finally use the internal sealing ring to make good the internal

hole, and check that the terminal is correctly located on the

outside wall (Where possible this should be visually checked

from outside the building.) Figure 20 shows a view of the flue

system, correctly installed.

d)

Assemble as shown in Figure 20

•

•

•

2

ALIGN ASSEMBLED

FLUE SYSTEM ELBOW TO

APPLIANCE AND SECURE

3

SLIDE INTERNAL

WALL SEALING RING

TO WALL TO FORM

A GOOD SEAL

1

INSERT

ASSEMBLED FLUE

SYSTEM FROM

INSIDE THE ROOM.

EXTERNAL WALL

SEALING RING

OPENS

130mm Dia.

HOLE WITH

WALL LINER

INTERNAL WALL

SEALING RING

•

FIBRE

SEAL FITTED

4.5.3

INSTALLING THE AIR/FLUE DUCT

FROM OUTSIDE THE BUILDING

(Flue hole diameter 100mm - wall liner not necessary)

a)

Secure the flue elbow with seal to the appliance using 4 screws.

b)

From outside the building, push the flue system through the wall

taking care to ensure that the terminal is the correct way around.

c)

Fit the internal wall sealing ring over the inside end of the flue,

then fit the air duct to the elbow, drill and secure with the two screws.

d)

Pull the flue system towards the boiler to seat the external

sealing ring against the outside wall.

e)

Finally use the internal sealing ring to make good the internal

hole. Check that the external wall sealing ring is correctly

located, on the outside wall from outside the building.

Figure 21 shows a view of the flue system, correctly installed.

•

•

•

•

•

4

REFIT AND SECURE

ELBOW TO AIR DUCT,

THEN TO APPLIANCE

1

FIT ELBOW

(AFTER SETTING CORRECT

LENGTH AND ALIGNMENT)

3

SLIDE INTERNAL

WALL SEALING RING

OVER AIRDUCT. PUSH

AGAINST THE WALL TO

FORM A GOOD SEAL

2

INSERT FLUE

LENGTHS FROM

OUTSIDE THE

ROOM. ENSURE

EXTERNAL WALL

SEALING RING

FORMS A GOOD

SEAL

•

EXTERNAL

WALL

SEALING

RING

TOP

100mm

Dia. HOLE

INTERNAL WALL

SEALING RING

•

FIBRE SEAL FITTED

INSTALLING THE FLUE SYSTEM

FROM OUTSIDE THE BUILDING

•

TOP

•

EXTERNAL

WALL

SEALING

RING