Supplied By www.heating spares.co Tel. 0161 620 6677

20

7.1

OVERHEAT CUT OFF DEVICE

a)

Pull off the two electrical connections.

b)

Unscrew the overheat cut off device from the flow (upper)

manifold.

c)

Fit the replacement overheat cut off device, do not overtighten

connect the electrical wires (polarity is not important), and

re-assemble the appliance in reverse order.

7.2

FLOW TEMPERATURE THERMISTOR

a)

Pull off the two electrical connections.

b)

Unscrew the thermistor from the flow (upper) manifold.

c)

Fit the replacement overheat cut off device ensuring a small

amount of thermal paste is applied to the end of the

thermistor, do not overtighten connect the electrical wires

(polarity is not important), and re-assemble the appliance in

reverse order.

7.3

AIR PRESSURE SWITCH

a)

Pull off the three electrical connections, noting their positions

on the switch.

b)

Unscrew the two screws retaining the switch.

c)

Remove the switch, carefully pulling off the silicon tubes.

d)

Fit the replacement switch, connect the silicon tubes and

connect the electrical wires, ensuring they are in the correct

position. Re-assemble the appliance in reverse order.

7.4

IGNITION PCB

(FULLY ENCLOSED)

a)

Pull off the 12 way plug on the front of the ignition device.

b)

Unscrew the single screw which retains the ignition box.

c)

Remove the box by pulling it forwards, the ignition and

detection leads should be pulled off the box at this stage.

d)

Fit a new ignition device. Re-assemble the appliance in

reverse order.

7.5

AQUASTAT PCB & HOUSING

a)

Unclip the aquastat housing from its mounting plate on the

top of the gas valve by slightly pressing the two sides of the

housing inwards and lifting the housing upwards and

forwards.

b)

Carefully turn this housing over, pull off the electrical

connections.

c)

Remove the potentiometer from the housing by undoing the

hexagonal nut.

d)

Fit a new Aquastat & housing. Re-assemble in reverse order.

PARTS REPLACEMENT

7

Before commencing any replacement operation, ISOLATE the

mains electrical supply, remove the front painted panel by sliding

up and then away from the boiler, remove the right hand portion

of the inner case by first pulling off the control knob, then

unscrewing the upper and lower right hand screws (Fig. 15) and

sliding the case away from the appliance. TURN OFF the gas

supply at the main service cock.

After any replacement operation, commission the boiler as follows:

a)

Turn on gas and check for gas soundness around boiler

components using leak detection fluid. DO NOT USE A

NAKED FLAME.

b)

Remove the outlet pressure test screw and fit pressure test

gauge (see Fig. 29).

c)

Ensure that all secondary controls (timer, room thermostat and

cylinder thermostat where fitted) are turned to maximum.

d)

Turn on the electrical supply and check the pump is working

and is circulating water through the system.

e)

Turn the boiler thermostat fully clockwise to its maximum

setting. After a few seconds the boiler will light. The burner

flame can be viewed through the viewing glass in the front of

the sealed door.

f)

If the boiler fails to light, and the ignition reset neon

illuminates, wait 15 seconds and reset the ignition by

depressing the reset button once.

g)

Allow the boiler to operate for 10 minutes

h)

The gas rate can now be set as required by adjusting the

governor on the gas valve. See Figure 29. Turn clockwise to

increase the flow. For heat output/pressure setting refer to

table 2.1.

i)

Turn off the boiler and remove the pressure test gauge and

refit the pressure test screw. Check for gas soundness with

leak detection fluid.

j)

Refit the painted right hand inner case with the two screws,

then refit the control knob.

k)

Make sure all secondary controls (e.g. timer, thermostat, etc.)

do control the boiler correctly.

l)

Turn the boiler thermostat and all external controls to the

required setting and refit the front panel.

30

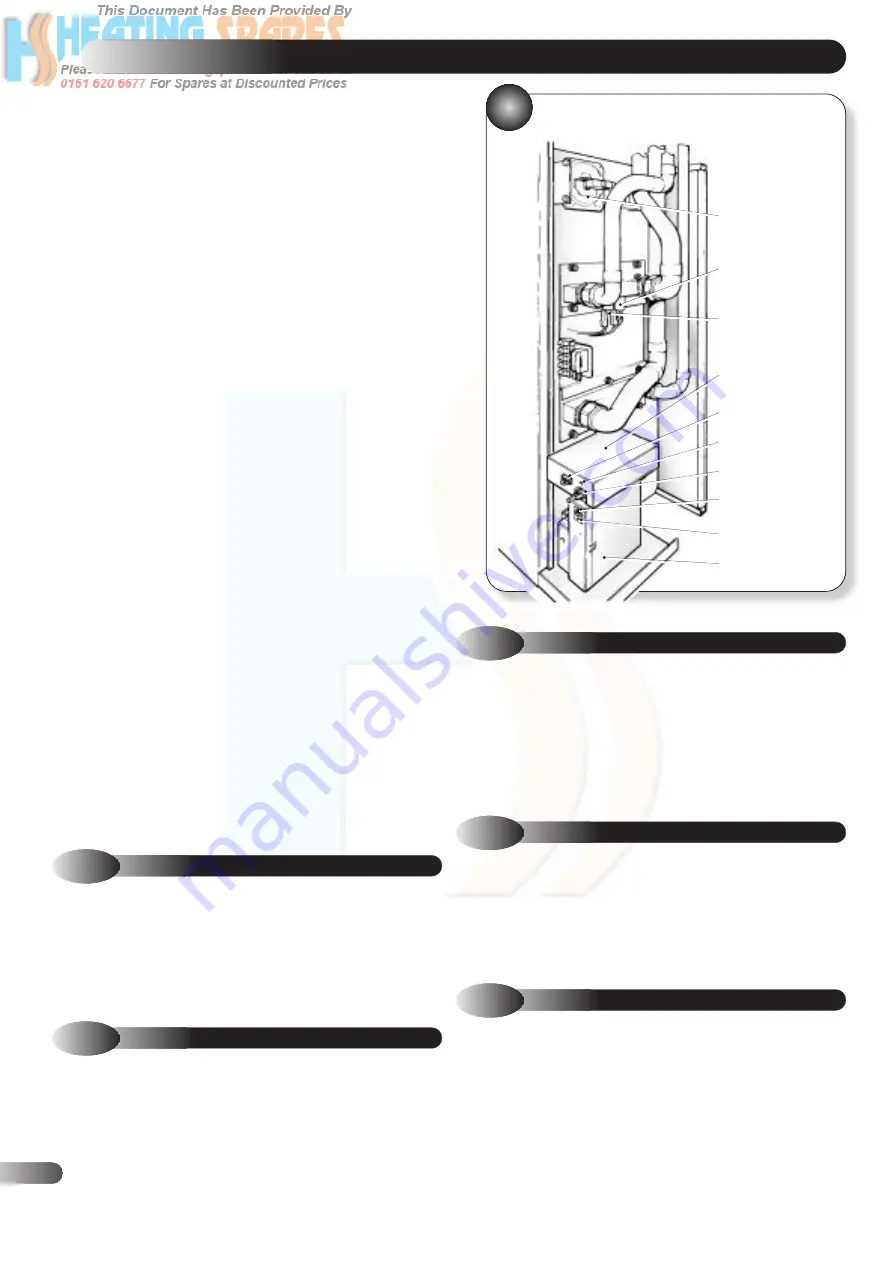

LOCATION OF SERVICEABLE

COMPONENTS

AIR PRESSURE

SWITCH

FLOW TEMPERATURE

THERMISTER

OVER HEAT

CUT OFF DEVICE

AQUASTAT PCB

(FULLY ENCLOSED)

JUMPER PLUG

OVERHEAT LOCKOUT

INDICATOR

TEMPERATURE CONTROL

POTENTIOMETER

IGNITION RESET

BUTTON

IGNITION LOCKOUT

INDICATOR

IGNITION DEVICE

(FULLY ENCLOSED)