Supplied By www.heating spares.co Tel. 0161 620 6677

23

23

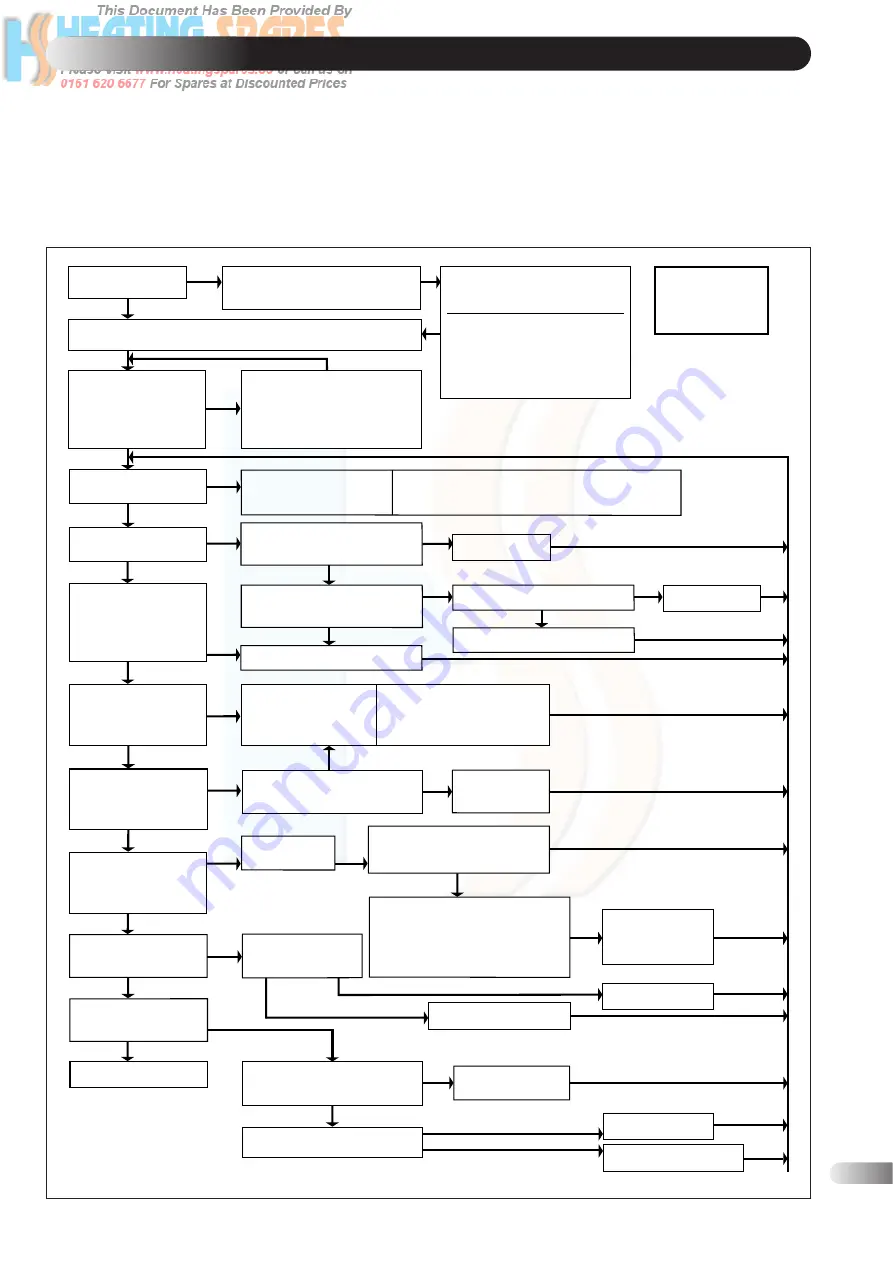

FAULT FINDING

9

Before proceeding through this fault finding guide, ensure all

connections to the electronic circuit board and the 12 way

connector to the ignition device are correctly fitted.

Carry out preliminary electrical safety checks in accordance with

‘Regulations for Electrical Installations’.

a)

Position the temperature control to 0.

b)

Turn ON external gas and electricity supplies.

c)

Ensure there is 230V at the permanent live ‘L’ on the

installation terminal block.

d)

Ensure there is 230V at the switched live ‘1’ on the installation

terminal block. This is the feed from the external controls,

they should be set to ON or MAXIMUM. A link between

terminals ‘L’ and ‘1’ will simulate the external controls

being ON.

Is the overheat

LED illuminated

Check 2Amp in-line fuse and replace if necessary.

If fuse continues to blow, check fan and pump for failure.

NO

YES

Switch off the permanent

supply to terminal "L" for 5

seconds minimum then back on.

The LED will now be out.

Investigate the cause of the

overheat situation and rectify.

Possible causes:

Lack of water

Lack of water flow

Faulty overheat thermostat

Faulty thermistor

Faulty aquastat

Turn the temperature

control knob to 6.

Is there 10vdc or 1vdc

at terminal 1 of the

igition control

connection

NOTE: The

Control System

incorporates an

Anti-cycle device

of 3 minutes.

The Thermistor, Potentiometer

or Aquastat PCB is faulty

re-place each in turn

separately to find and

rectify the fault.

1Vdc

Is the ignition Lock-out

neon illuminated.

Allow 15 seconds

minimum then depress

the ignition reset button

In the event of ignition lockout, turn thermostat

to maximum setting and ensure programmer

is switched on before pressing reset button.

YES

NO

Replace the fan

Is there 230V at the fan motor.

Replace the fan

YES

NO

Check the wiring and rectify.

Does the fan start

to run.

NO

NO

Disconnect fan leads from fan

motor. Is there between 40-50

ohms across fan motor.

YES

YES

Is there 230V at terminal

'8' on the ignition control

connection.

NO

Replace the ignition device.

Is there 230V at

terminal '7' on the

ignition control

connection.

YES

NO

Is there 230V at

terminal '5' on the

ignition control

connection.

YES

YES

Air pressure switch

has not changed over,

investigate and rectify.

Possible causes:

Air pressure switch faulty

Fan performance poor

Flue/Air duct blocked

Is there 230V at

terminal '6' on the

ignition control

connection.

NO

NO

Replace the

overheat

thermostat

YES

NO

Replace the

ignition device.

Does the gas valve open

and allow gas to the

main burner injector.

YES

Does the gas valve

open and allow gas

to the main burner

injector.

YES

NO

Is there a spark

between the ignitor

and the burner.

YES

Check the condition

of the electrode

and its lead.

NO

NO

Check the adjustment of the

gas valve. If this does not rectify

the fault replace the gas valve.

The original ignition device should

be used on the new valve.

It is unlikely both will be faulty.

Does the boiler ignite

and continue to

operate satisfactorily.

YES

Operation normal.

YES

SATISFACTORY

FAULTY

Replace ignition device.

Replace assembly.

Does the gas valve

open and allow

gas to the main

burner injector.

Is there 230V at terminal

N/O on the air pressure

switch.

YES

Does the burner ignite and

extinguish after approximately

10 seconds.

NO

Check the condition of the

flame sensor and its lead.

YES

Check the spark

gap and rectify.

Replace assembly.

Replace ignition device.

FAULTY

SATISFACTORY