Supplied By www.heating spares.co Tel. 0161 620 6677

7

INSTALLATION REQUIREMENTS

3

The following limitations MUST be observed when siting

the boiler:

a)

The boiler is not suitable for external installation. The position

selected for installation should be within the building, unless

otherwise protected by a suitable enclosure, and MUST allow

adequate space for installation, servicing, and operation of the

appliance, and for air circulation around it. (Section 2.4 and 3.4)

b)

This position MUST allow for a suitable flue system and

terminal position. (Section 2.5 and 3.3) The boiler must be

installed on a flat vertical wall which is capable of supporting

the weight of the appliance and any ancillary equipment.

c)

If the boiler is to be fitted in a timber framed building it

should be fitted in accordance with the British Gas publication

‘Guide for Gas Installations In Timber Frame Housing’,

Reference DM2. If in doubt, advice must be sought from the

Local Gas Region.

d)

If the appliance is to be installed in a room containing a bath

or a shower, any electrical switch or control utilising mains

electricity must be so situated that it cannot be touched by a

person using the bath or shower. Attention is drawn to the

requirements of the current I.E.E. Wiring Regulations, and in

Scotland the electrical provisions of the Building Regulations

applicable in Scotland.

e)

A compartment used to enclose the appliance MUST be

designed and constructed specifically for this purpose. An

existing cupboard, or compartment, may be used provided it

is modified accordingly. BS 5376:2 gives details of the

essential features of cupboard / compartment design,

including airing cupboards.

f

) Where installation will be in an unusual location, special

procedures may be necessary. BS 6798 gives detailed

guidance on this aspect.

Detailed recommendations for flue installation are given in

BS 5440:1. The following notes are for general guidance.

a)

The boiler MUST be installed so that the terminal is exposed to

the external air.

3.1

STATUTORY REQUIREMENTS

3.2

BOILER LOCATION

SAFETY (INSTALLATION AND USE) REGULATIONS 1984 (AS AMENDED).

It is the law that all gas appliances are installed by a registered

person, in accordance with the above regulations. Failure to install

appliances correctly could lead to prosecution. It is in your own

interest, and that of safety, to ensure that the law is complied with.

In addition to the above regulations, this appliance must be

installed in accordance with the current IEE Wiring Regulations for

electrical installation, local building regulations, the Building

Standards (Scotland) (Consolidation) Regulations, bye laws of the

local water undertaking and Health and Safety Document No.

635 The Electricity at Work Regulations 1989.

It should also be in accordance with the relevant recommenda-

tions in the current editions of the following British Standards and

Codes of Practice: BS5449:1, BS5546, BS5440:1, BS5440-.2,

BS6798, BS6891, BG.DM2 and BS7074

IMPORTANT NOTE:

Manufacturer instructions must NOT be

taken in any way as overriding statutory obligations.

9

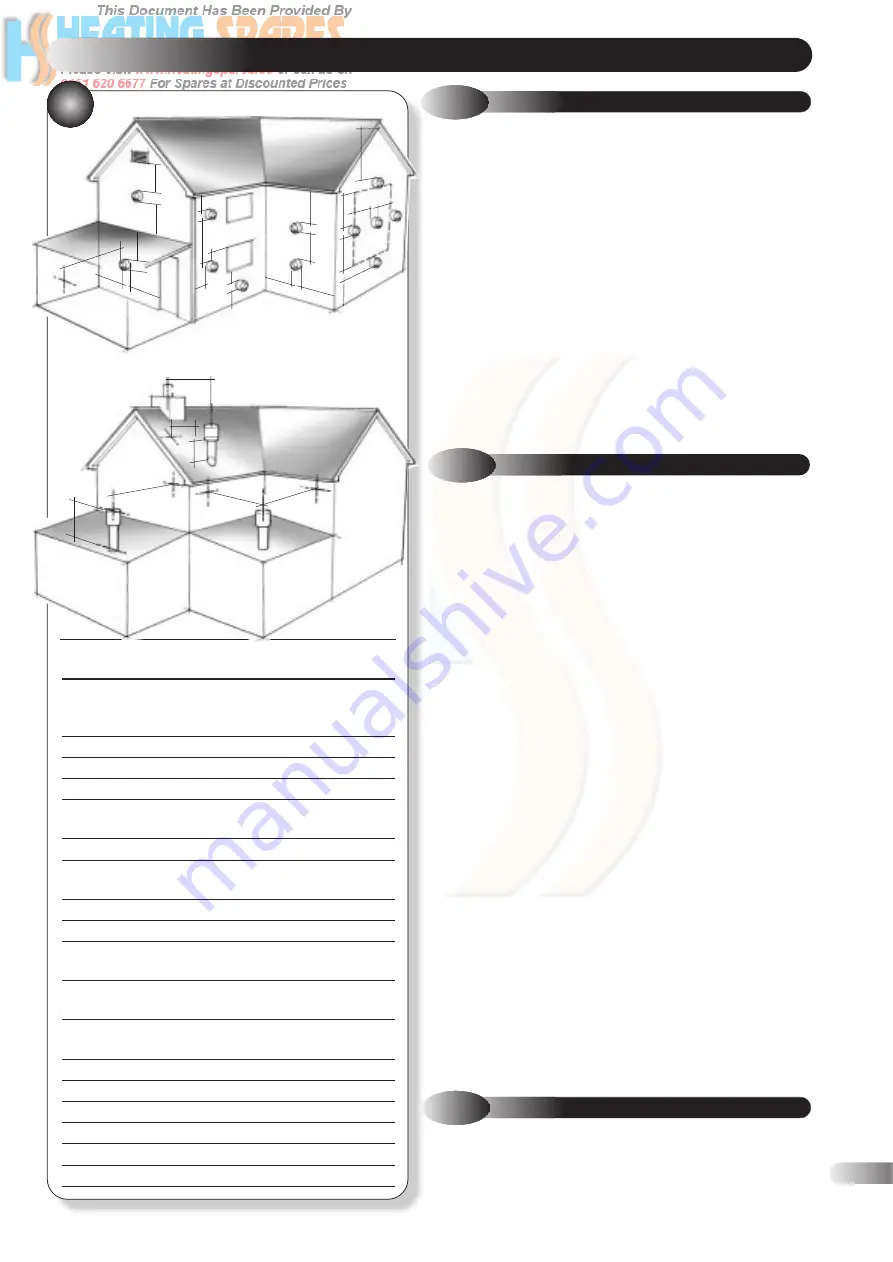

FLUE TERMINAL POSITION

Position Minimum

spacing

A

Directly below an openable window, 300mm

12in

air vent, or any other ventilation

opening

B

Below gutter, drain/soil pipe

75mm

3in

C

Below eaves

200mm

8in

D

Below a balcony

200mm

8in

E

From vertical drain pipes and

75mm

3in

soil pipes

F

From internal or external corners

300mm

12in

G

Above adjacent ground or

balcony level

300mm

12in

H

From a surface facing the terminal

600mm

24in

I

Facing terminals

1200mm

48in

J

From opening (door/window) in

1200mm

48in

carport into dwelling

K

Vertically from a terminal on the

1500mm

60in

same wall

L

Horizontally from a terminal on the

300mm

12in

same wall

M

Adjacent to opening

300mm

12in

N

Below carport

600mm

24in

O

From adjacent wall

300mm

12in

P

From adjacent opening window

1000mm

40in

Q

From another terminal

600mm

24in

R

Minimum height

300mm

12in

•

A

•

•

G

•

•

D,N

•

•

H,I

•

•

F

••

•

J

•

•

B,C

•

•

K

•

•

M

•

•

E

•

•

A

•

•

G

•

•

B,C

•

•

K

•

•

F

•

•

F

•

•

C

•

•

K

•

•

K

•

•

G

• •

L

• •

L

•

•

P

•

•

300mm

MIN.

•

•

•

•

Q

•

•

R

•

O

430 mm

MIN.

•

•

O

SPECIAL REQUIREMENTS FOR A

VERTICALLY BALANCED FLUE

FLUE TERMINAL POSITION

3.3