Supplied By www.heating spares.co Tel. 0161 620 6677

25

SUPPLEMENT 1

11

33

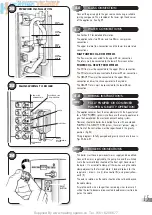

FLUE SYSTEM ASSEMBLY

AND DIMENSIONS

Supplementary instructions for flue systems with a vertical outlet.

a)

Read the installation requirements and flue specifications

described in section 3.

b)

Follow the installation procedure described in section 4 up to

section 4.7 (but making the necessary hole(s) in section 4.2 in

the ceiling/roof instead of the wall). Use the following

instructions in place of section 4.7.

c)

Measure the vertical distance from the top of the boiler case

to the roof line (Fig. 33). Use this length to calculate the

number of extension ducts required.

d)

Starting at the boiler, fit the vertical socket, standard duct and

extensions required. Then fit the adaptor.

e)

Now working from outside fit the Balanced flue roof terminal,

ensuring the roof flashing and sealing components are

secured to the roof.

f)

Ensure the inner and outer ducts are correctly fitted to the

adaptor.

Note: All the joints should be secured using the self-tapping screws supplied.

••

•

•

•

•

•

•

•

•

•

180mm

430mm

1046mm

max

30mm

767mm

767mm

767mm

425mm

50mm

See Figure 7 (page 6)

BALANCED FLUE

ROOF TERMINAL

•

ROOF LINE

•

100/60mm TO

118/80mm DIA

ADAPTOR

•

100/60mm DIA

EXTENSION DUCT

•

STANDARD DUCT

•

100/60mm DIA

EXTENSION DUCT

•

100/60mm DIA

EXTENSION DUCT

•

•

VERTICAL

SOCKET

•

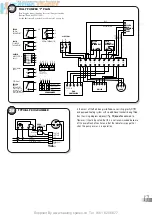

SUPPLEMENT 2

12

Supplementary instructions for flue systems incorporating

an additional 90° elbow.

a)

Read and follow the installation procedure described in the

main section of the installation instructions up to section 4.2.

b)

Using information given earlier in this booklet determine

where the boiler and flue are to be positioned and make the

necessary hole in the wall(s) for the air/flue duct as defined in

section 4.2.

c)

Install the boiler as described in section 4 with the exception

of the flue system (4.5)

d)

Using the information and dimensions in Figures 3 to 7 shown

earlier in this booklet calculate the lengths required for each

duct.

e)

Cut each duct to length, ensuring that each cut is square and

free from burrs.

f)

Starting at the terminal end assemble the ducts and elbows,

and work back towards the boiler.

IMPORTANT NOTE:

All flue joints must be secured by two self-tapping

screws through the air duct as illustrated.

For installations that require longer vertical or horizontal flue

lengths a twin pipe system is available. Refer to separate flue

booklet for further information.

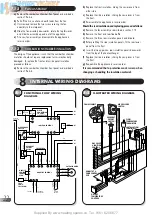

34

These supplementary instructions must be read in conjunction with the

Installation and Servicing Instructions supplied with the appliance.

The entry of the concentric air/flue duct should be as close to the

centre of the entry face of the SE-DUCT as possible. It is very

important that the concentric air/flue duct is not positioned in the

corner of the SE-DUCT.

The standard flue kit supplied with the appliance is suitable for

installation in a SE-DUCT application. The appliance Installation

and Servicing Instructions should be used for the complete

installation with the exception of the following.

1 The external wall sealing ring should not be fitted.

2 The end of the air duct should be fitted flush with the inside of

the SE-DUCT as shown in the diagram below.

3 Horizontal flue installations only are suitable for SE-DUCT

applications.

SE-DUCT APPLICATIONS

CONCENTRIC AIR/FLUE

DUCT POSITION FOR

SE-DUCT APPLICATION

Seal the gap between the

SE-DUCT wall and the

100mm Dia.

appliance

air inlet

duct.

SE-DUCT

•

•