23

2000225116B

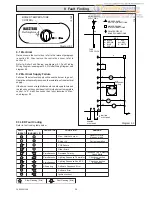

IMPORTANT. On completion of the Fault Finding task which has required the breaking and remaking of the electrical connections,

the continuity, polarity, short circuit and resistance to earth checks must be repeated using a suitable multimeter.

WARNING. The multifunctional control and fan operate on mains voltage, the terminal will be live.

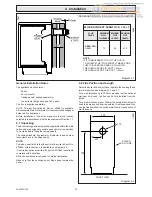

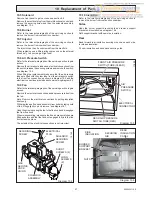

Diagram 9.1

ELECTRICAL FAULT FINDING

12062

9 Fault Finding

Diagram 8.12

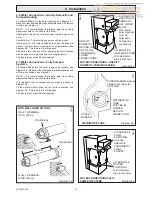

ELECTRODE

0000

SECURING

SCREW

+

-

SPARK GAP

= 3.6 1.1

Diagram 8.11

BURNER

INJECTOR

GRAPHITE

COATED

NUT(2)

0939

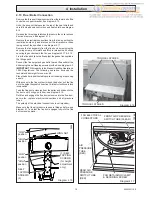

8 Servicing

No

No

No

Before carrying out fault finding, ensure that gas, electricity and water are available to the boiler.

Ensure that any external controls are calling for heat and circuit water is cold.

If Reset LED is lit - check water system for overheating, reset by turning temperature control knob

off and on. If the LED coding is showing an ignition failure, reset the boiler by turning the control

knob off and on. Do not operate the boiler without combustion chamber front fitted.

Control Knob at '0'

Apply heating demand

(turn potentiometer clockwise)

Power ON at isolation switch

Does the fan run for 10 seconds with RESET LED lit

Replace fuse

Does the unit begin to spark

Replace PCB

Does the fan start

Is there an LED sequence

Turn Gas ON

Is there an LED sequence

Is the Gas turned ON

Replace PCB

Replace PCB

Correct Operation

Does the burner light

Refer to table

Refer to table

Switch OFF

Remake connections

Restart diagnosis

Are the HT & Earth

connections made

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

Refer to table

Yes

Yes

Yes

Yes

No

No

No